AgZrB2-Gr contact material with excellent material transfer resistance property and preparing method thereof

A contact material, zrb22.0 technology, applied in the direction of contacts, electrical components, circuits, etc., can solve the problems of rising surface temperature, increasing contact resistance, affecting the stability and service life of electrical appliances, and achieving excellent corrosion resistance Effects of high performance and welding resistance, lower sintering temperature, and excellent material transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

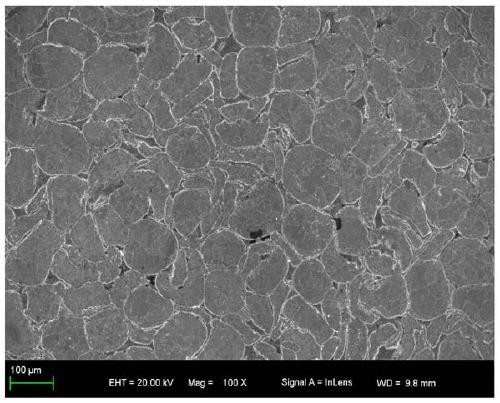

[0030] Example 1. As figure 1 , figure 2 and Figure 4 , Figure 5 As shown, a AgZrB with excellent material transfer resistance 2 -Gr contact material, consisting of the following components by mass percentage:

[0031] Ag 95.8wt.%;

[0032] ZrB 2 4.0wt.%;

[0033] Gr 0.2wt.%;

[0034] The sum of the mass percentages of the above components is 100%.

[0035] The purity of raw materials is greater than 99.99%, and the particle size of Ag powder is 72 μm; ZrB 2 Powder size 50nm;

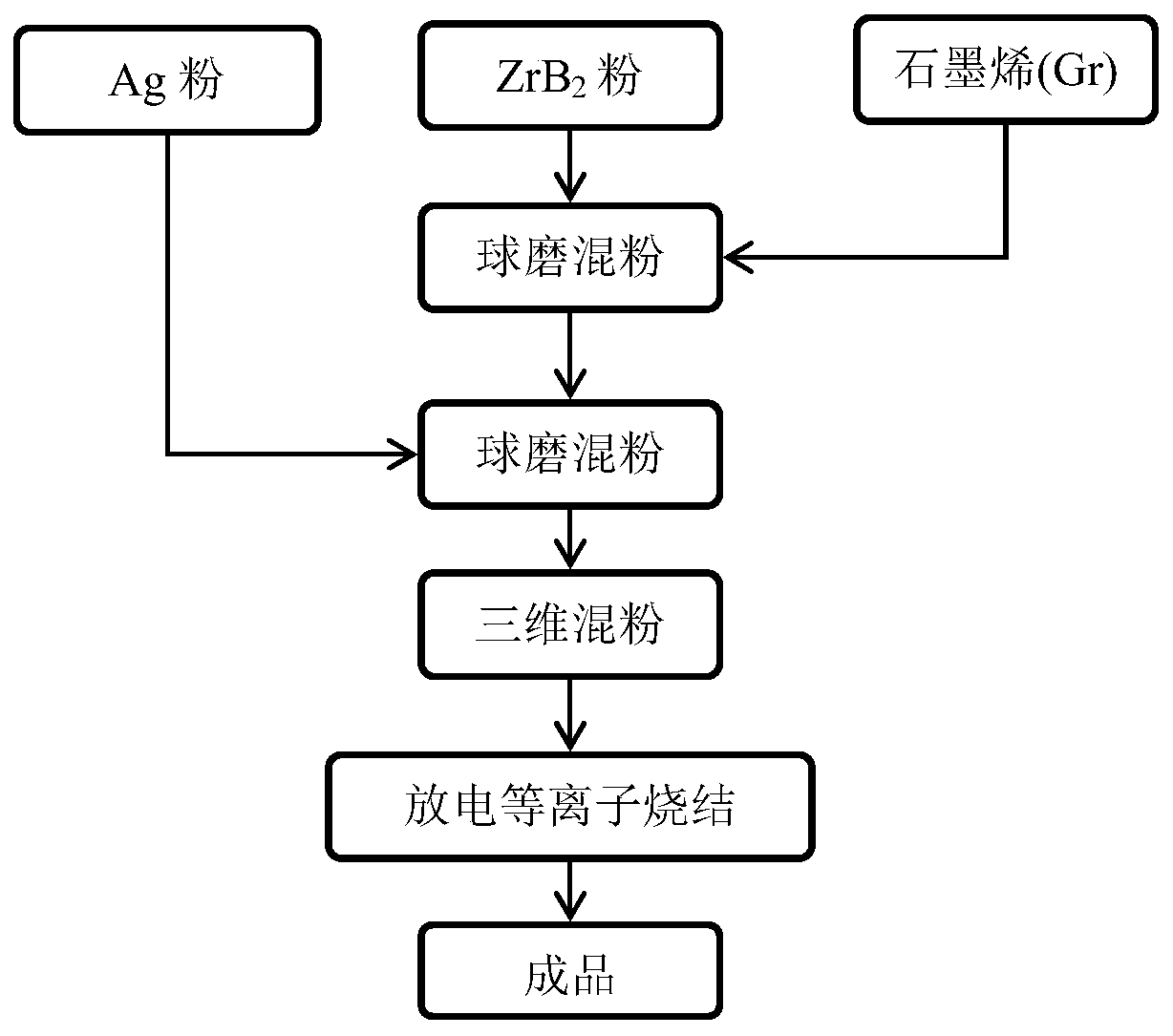

[0036] AgZrB with excellent material transfer resistance 2 -The preparation method of the Gr contact material, the specific operation steps are as follows:

[0037] Step 1. Follow AgZrB 2 - Ag powder, Gr powder and ZrB required for calculating the composition ratio of Gr contact material 2 The amount of powder is weighed for later use.

[0038] Step 2. The weighed ZrB 2 , Gr powder is mixed in a planetary ball mill;

[0039] Step 3. Add the weighed Ag powder to the planetary ball mil...

Embodiment 2

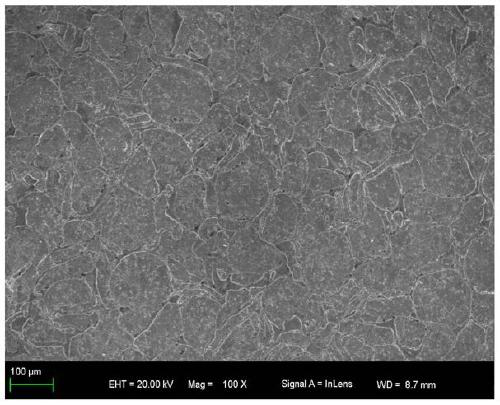

[0049] Example 2. If image 3 As shown, a AgZrB with excellent material transfer resistance 2 -Gr contact material, the difference between this example and Example 1 is:

[0050] It consists of the following components by mass percentage:

[0051] Ag 95.6wt.%;

[0052] ZrB 2 4.0wt.%;

[0053] Gr 0.4wt.%;

[0054] The sum of the mass percentages of the above components is 100%.

[0055] The purity of raw materials is greater than 99.99%, and the particle size of Ag powder is 72 μm; ZrB 2 Powder size 50nm;

[0056] AgZrB with excellent anti-material transfer performance in Example 1 2 - The difference in the preparation method of the Gr contact material is:

[0057] In step 1, Ag powder 286.8g, ZrB 2 Powder 12g and graphene 1.2g.

[0058] In step 2, the powder mixing time in the planetary ball mill is 28 hours, the rotating speed is 370rpm, and the ball-to-material ratio is 20:1.

[0059] The time to continue mixing powder in step 3 is 4h, the rotating speed is 300r...

Embodiment 3

[0064] Example 3. A kind of AgZrB with excellent material transfer resistance 2 -Gr contact material, the difference between this example and Example 1 is that it consists of the following components by mass percentage:

[0065] Ag 97.95wt.%;

[0066] ZrB 2 2.0wt.%;

[0067] Gr 0.05wt.%;

[0068] The sum of the mass percentages of the above components is 100%.

[0069] The purity of raw materials is greater than 99.99%, and the particle size of Ag powder is 72 μm; ZrB 2 Powder size 50nm;

[0070] AgZrB with excellent anti-material transfer performance in Example 1 2 - The difference in the preparation method of the Gr contact material is:

[0071] In step 1, Ag powder 293.85g, ZrB 2 powder 6g and graphene 0.15g.

[0072] In step 2, the powder mixing time in the planetary ball mill is 10 hours, the rotating speed is 300 rpm, and the ball-to-material ratio is 10:1.

[0073] The time to continue mixing powder in step 3 is 2h, the rotating speed is 200rpm, and the ball-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com