Wall fixing agent modified resin polymer for drilling fluid

A technology of modified resin and wall-bonding agent, which is applied in the field of petroleum drilling aids, wall-bonding agent-modified resin polymers for drilling fluids, and resin polymers modified by wall-bonding agents for drilling fluids, and can solve the problem of strengthening rock Insufficient cementation effect, reduced fluid loss, material toxicity, etc., to avoid wellbore collapse, enhance wellbore stability, and reduce fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

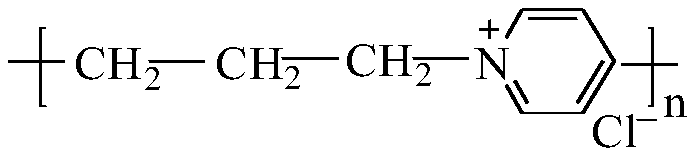

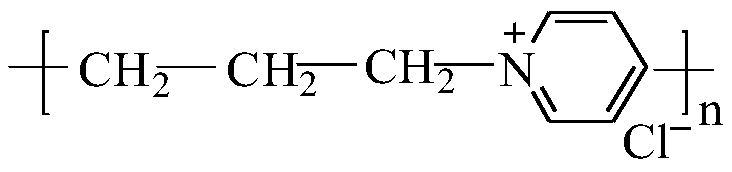

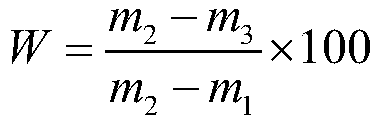

Image

Examples

Embodiment 1

[0022] Embodiment 1: The wall-solidifying agent modified resin polymer for drilling fluid of the present invention is made of the raw materials of the following mass ratio: 200 parts of clear water, 20 parts of starch, and the mass percent concentration is 40% hydrogen 9 parts of sodium aqueous solution, 7 parts of 2-chloroethyltrimethylammonium chloride, 25 parts of acrylamide, 15 parts of methacryloyloxyethyltrimethylammonium chloride, 0.5 parts of initiator, nitrohumic acid 10 parts of potassium, 15 parts of pseudo-boehmite, 25 parts of auxiliary agent; the starch is corn flour; the particle size of the pseudo-boehmite is 120 mesh; the auxiliary agent is MgO, Al 2 o 3 Combination of two raw materials, MgO and Al 2 o 3 The mass ratio of potassium permanganate and potassium vanadate is 1.5:1. The initiator is a combination of potassium permanganate and potassium vanadate. The preparation method of the described wall-solidifying agent-modified resin polymer for drilling flu...

Embodiment 2

[0023] Embodiment 2: The wall-solidifying agent modified resin polymer for drilling fluid of the present invention is made of the raw materials of the following mass ratio: 210 parts of clear water, 25 parts of starch, and the mass percent concentration is 40% hydrogen 8 parts of sodium aqueous solution, 7 parts of 2-chloroethyltrimethylammonium chloride, 30 parts of acrylamide, 10 parts of methacryloyloxyethyltrimethylammonium chloride, 0.75 parts of initiator, nitrohumic acid 15 parts of potassium, 20 parts of pseudo-boehmite, 30 parts of auxiliary agent; the starch is sweet potato powder; the particle size of the pseudo-boehmite is 140 mesh; the auxiliary agent is MgO, Al 2 o 3 Combination of two raw materials, MgO and Al 2 o 3 The mass ratio of potassium permanganate and potassium vanadate is 1.5:1; the initiator is a combination of two raw materials, potassium permanganate and potassium vanadate, and the mass ratio of potassium permanganate and potassium vanadate is 1:1...

Embodiment 3

[0024] Embodiment 3: The wall-solidifying agent modified resin polymer for drilling fluid according to the present invention is made from the raw materials of the following mass ratio: 220 parts of clear water, 30 parts of starch, and a mass percent concentration of 40% hydrogen 10 parts of sodium aqueous solution, 9 parts of 2-chloroethyltrimethylammonium chloride, 25 parts of acrylamide, 20 parts of methacryloyloxyethyltrimethylammonium chloride, 0.9 parts of initiator, nitrohumic acid 15 parts of potassium, 15 parts of pseudo-boehmite, 30 parts of auxiliary agents; the starch is tapioca flour; the particle size of the pseudo-boehmite is 160 mesh; the auxiliary agents are MgO, Al 2 o 3 Combination of two raw materials, MgO and Al 2 o 3 The mass ratio of potassium permanganate and potassium vanadate is 1:2. The initiator is a combination of two raw materials, potassium permanganate and potassium vanadate. The preparation method of the described wall-solidifying agent-modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com