Environment-friendly high-temperature-resistant conveying belt binder and preparation method thereof

A binder and high temperature resistant technology, used in non-polymer adhesive additives, adhesives, grafted polymer adhesives, etc., can solve problems such as poor performance, achieve excellent viscosity, and improve the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 4.5g of chloroprene rubber in 40ml of ethyl acetate at a temperature of 60°C, stir evenly, add 5mg of BPO, continue stirring for 15min, then add 3ml of methyl methacrylate dropwise to the mixed liquid system, and dissolve the remaining 10mg of BPO into ethyl acetate, then heat the mixture to 75°C, continue to stir for 5-6 hours, and finally add 6 mg of 2,4,6-trinitrophenol, and continue to stir for 1 hour; to obtain a grafted chloroprene rubber copolymer;

[0018] Pour 35g of trichlorethylene, 2g of tert-butyl phenolic resin and 40mg of active magnesium oxide into 3ml of water, stir at high speed for 7-9h to obtain an aqueous solution; then pour the grafted neoprene copolymer and 40mg of anti-aging agent D50 into the above aqueous solution , continue to stir at a high speed for 15-25 hours to obtain the mixed solution 1; mix the mixed solution 1 with 0.4 g of tetraisocyanate and stir evenly to obtain the binder.

Embodiment 2

[0020] Dissolve 5.5g of neoprene in 40ml of ethyl acetate at a temperature of 70°C, stir evenly, add 6mg of BPO, continue stirring for 20min, then add 4.0ml of methyl methacrylate dropwise to the mixed liquid system, and dissolve the remaining 12mg of BPO Dissolve in ethyl acetate, then heat the mixture to 85°C, continue to stir for 6h, finally add 6mg of 2,4,6-trinitrophenol, continue to stir for 1h; obtain grafted chloroprene rubber copolymer;

[0021] Pour 45g of trichlorethylene, 4g of tert-butyl phenolic resin and 90mg of active magnesium oxide into 5ml of water, stir at high speed for 9h to obtain an aqueous solution; then pour the grafted neoprene copolymer and 40mg of anti-aging agent D50 into the above aqueous solution, Continue to stir at a high speed for 25 hours to obtain the mixed solution 1; mix the mixed solution 1 with 0.5 g of tetraisocyanate and stir evenly to obtain the binder.

Embodiment 3

[0023] Dissolve 4.8g of chloroprene rubber in 35ml of ethyl acetate at a temperature of 65°C, stir evenly, add 4mg of BPO, continue stirring for 15min, then add 3.4ml of methyl methacrylate dropwise to the mixed liquid system, and dissolve the remaining 8mg of BPO Dissolve in ethyl acetate, then heat the mixture to 80°C, continue to stir for 5.5 hours, finally add 6 mg of 2,4,6-trinitrophenol, and continue to stir for 1 hour to obtain a grafted chloroprene rubber copolymer;

[0024] Pour 40g of trichlorethylene, 3g of tert-butyl phenolic resin and 60mg of active magnesium oxide into 4ml of water, stir at high speed for 8h to obtain an aqueous solution; then pour the grafted neoprene copolymer and 50mg of anti-aging agent D50 into the above aqueous solution, Continue high-speed stirring for 15-25 hours to obtain the mixed solution 1; mix the mixed solution 1 with 0.45 g of tetraisocyanate and stir evenly to obtain the binder.

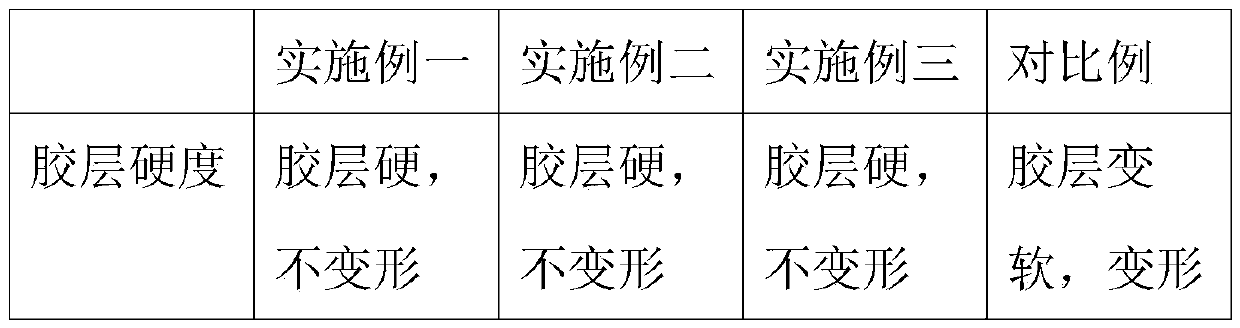

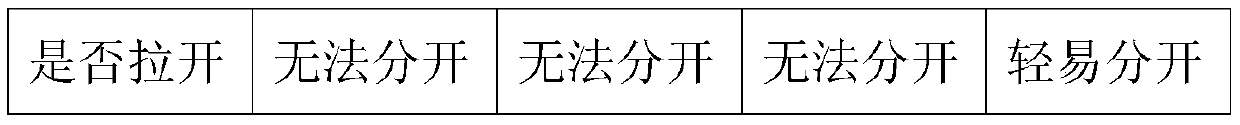

[0025] Cut the polyester canvas into 8 squares of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com