Pressure-sensitive adhesive tape capable of being repeatedly adhered and preparation method thereof

A technology of pressure-sensitive tape and pressure-sensitive adhesive, which is applied in the field of pressure-sensitive adhesive and can solve problems such as loss of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The embodiment of the present invention also provides the preparation method of the pressure-sensitive tape that can be pasted repeatedly, comprising the following steps:

[0045]1) Preparation of the dispersed phase: weigh isooctyl acrylate, methyl methacrylate, acrylic acid, hydroxyethyl acrylate, acetoacetoxyethyl methacrylate, glycidyl methacrylate and initiator , stirring and mixing uniformly to obtain the dispersed phase;

[0046] 2) Preparation of the continuous phase: Weigh the non-ionic surfactant, anionic surfactant and polymer dispersant in proportion, add deionized water and control the oil-water ratio to 1:1.5-3, stir and mix evenly, A continuous phase is produced;

[0047] 3) Preparation of emulsion: add the dispersed phase into the storage tank of the SPG membrane emulsification device, and extrude to the continuous phase through the through hole on the SPG membrane under the pressure of nitrogen to form the emulsion. 0.02~0.08Mpa; Stirring keeps the em...

Embodiment 1

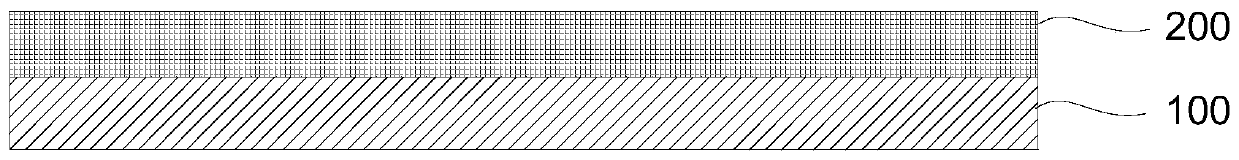

[0060] A pressure-sensitive adhesive tape that can be pasted repeatedly in this embodiment includes a substrate 100 and a microsphere pressure-sensitive adhesive coating 200 disposed on the surface of the substrate 100 . The microspherical pressure-sensitive adhesive coating 200 includes the following raw materials by mass percentage: 75kg of isooctyl acrylate; 6kg of methyl methacrylate; 2kg of acrylic acid; 6kg of hydroxyethyl acrylate; 3kg of methyl Acetoacetoxyethyl acrylate; 1.5kg of nonionic surfactant; 4.5kg of anionic surfactant; 1kg of polymer dispersant; 1kg of initiator.

[0061] The initiator includes the following raw materials: benzoyl peroxide and 2,2-azobisisobutyronitrile, the mass ratio of which is 1:0.8. The base material 100 is a polyethylene foam plastic base material 100, and its density is 60kg / m 3 .

[0062] The embodiment of the present invention also provides the preparation method of the pressure-sensitive tape that can be pasted repeatedly, compri...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that the microspherical pressure-sensitive adhesive coating 200 includes the following raw materials in terms of mass percentage: 79kg of isooctyl acrylate; 4kg of methyl methacrylate; 2kg of Acrylic acid; 4kg of hydroxyethyl acrylate; 2kg of acetoacetoxyethyl methacrylate; 1.2kg of nonionic surfactants; 2.2kg of anionic surfactants; 0.5kg of polymer dispersants; 0.3kg The initiator of; The thickener of 3kg, the plasticizer of 0.8kg, the glycidyl methacrylate of 0.5kg and the antifungal agent of 0.5kg.

[0073] In the preparation method of the described re-pastable pressure-sensitive adhesive tape provided in this embodiment:

[0074] 3) Preparation of the dispersed phase: weigh isooctyl acrylate, methyl methacrylate, acrylic acid, hydroxyethyl acrylate, acetoacetoxyethyl methacrylate, glycidyl methacrylate and initiator , stirring and mixing uniformly to obtain the dispersed phase.

[0075] 7) Glue compoundin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com