Polytetrafluoroethylene composite material

A technology of polytetrafluoroethylene and polytetrafluoroethylene resin, which is applied in the field of polytetrafluoroethylene composite materials, can solve the problems of reducing density and increasing material water absorption, so as to increase steric hindrance and increase compatibility sex, avoiding reunion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

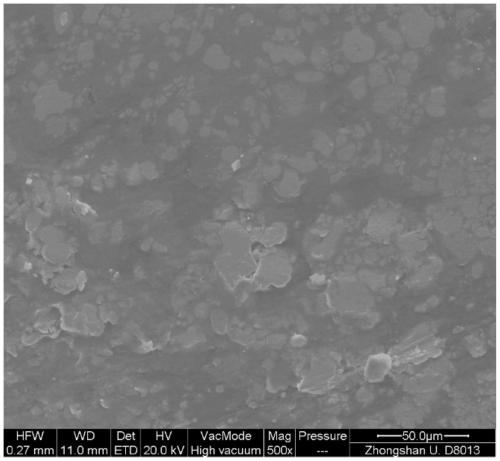

Embodiment 1

[0032] As a polytetrafluoroethylene composite material of an embodiment of the present invention, the polytetrafluoroethylene composite material is composed of the following components by weight: 80 parts of polytetrafluoroethylene resin, 5 parts of fluorinated graphene, 0.1 1 part of glass fiber and 1 part of antimony trioxide. The preparation method of the present embodiment polytetrafluoroethylene composite material comprises the following steps:

[0033] (I) Disperse the polytetrafluoroethylene resin, fluorinated graphene, glass fiber and antimony trioxide in the carboxylic acid modified macromolecular dispersant solution according to the weight ratio, stir at 300r / min for 30min and then separate the solid from the liquid. Collect the solid and dry at 120°C for 2 hours, wherein the solvent of the carboxylic acid modified macromolecular dispersant solution is ethanol, and the mass concentration of the solute in the carboxylic acid modified macromolecular dispersant solution...

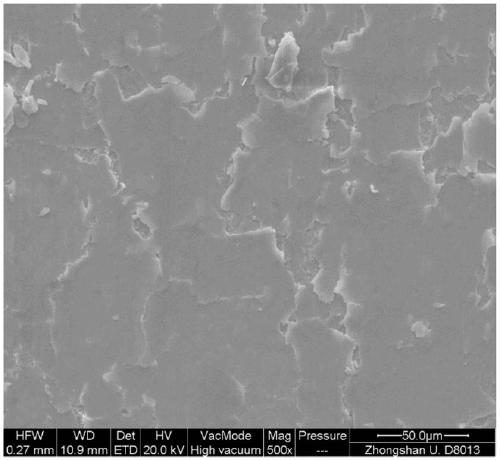

Embodiment 2

[0040] As a polytetrafluoroethylene composite material in an embodiment of the present invention, the polytetrafluoroethylene composite material is composed of the following components by weight: 99 parts of polytetrafluoroethylene resin, 0.1 part of fluorinated graphene, 19 Part glass fiber and 0.1 part antimony trioxide.

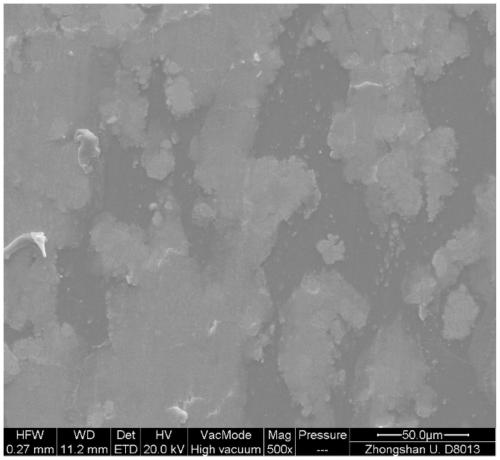

Embodiment 3

[0042] As a kind of polytetrafluoroethylene composite material of the embodiment of the present invention, described polytetrafluoroethylene composite material is made up of the following components by weight: 90 parts of polytetrafluoroethylene resin, 3 parts of fluorinated graphene, 15 parts Part glass fiber and 0.5 part antimony trioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com