Preparation method of biomedical magnesium alloy wire

A biomedical and magnesium alloy technology is applied in the field of preparation of biomedical magnesium alloy wire, which can solve the problems of limited size of magnesium wire, unsuitable for large-scale production, large material processing loss, etc., and achieves improvement of microstructure, strength and plasticity. and corrosion resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the composition of the Mg-2Zn-0.5Nd alloy is by weight percentage: 2% Zn, 0.5% Nd, and the balance is Mg.

[0032] Preparation method: by weight percentage, pure magnesium, 2% Zn, 0.5% Nd are smelted into liquid metal, cast into slabs, surface defects and impurities are removed, the slabs are subjected to homogenization heat treatment at 300°C for 5 hours, and passed through hot rolling ( The furnace temperature is 480°C, the heating time is 4h), processed into a magnesium alloy plate with a thickness of 70mm, a width of 540mm, and a length of 400mm; 400mm magnesium alloy sheet; then the sheet is processed into a magnesium alloy sheet with a thickness of 2mm, a width of 540mm, and a length of 400mm by hot rolling (out of furnace temperature 440°C, heating time 2h).

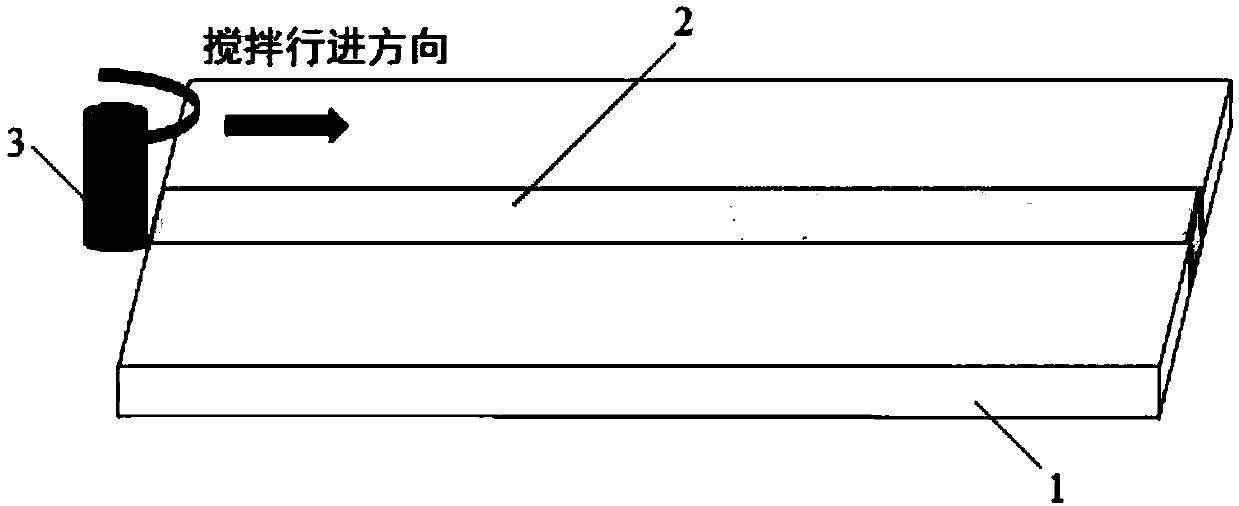

[0033] Such as figure 1 As shown, the magnesium alloy plate 1 is processed by a mechanical stirring process, the direction of the mechanical stirring is along the rolling direction of t...

Embodiment 2

[0039] In this embodiment, the composition of the Mg-0.2Zn-2.0Nd alloy is by weight percentage: 0.2% Zn, 2.0% Nd, and the balance is Mg.

[0040] Preparation method: by weight percentage, pure magnesium, 0.2% Zn, 2.0% Nd are smelted into liquid metal, cast into a flat ingot, surface defects and impurities are removed, the flat ingot is subjected to homogenization heat treatment at 320 ° C for 5 hours, and passed through hot rolling ( The furnace temperature is 480°C, the heating time is 4h), processed into a magnesium alloy plate with a thickness of 70mm, a width of 540mm, and a length of 400mm; 400mm magnesium alloy sheet; then the sheet is processed into a magnesium alloy sheet with a thickness of 2mm, a width of 540mm, and a length of 400mm by hot rolling (out of furnace temperature 440°C, heating time 2h).

[0041] Such as figure 1 As shown, the magnesium alloy plate 1 is processed by a mechanical stirring process, the direction of the mechanical stirring is along the rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com