A kind of eggshell silver catalyst and its preparation method and application

A silver catalyst and eggshell technology, applied in the field of eggshell silver catalyst and preparation thereof, can solve the problems of complex catalyst preparation technology, decreased catalyst activity, complicated preparation of silver solution, etc., and achieve good economic benefits and industrial application prospects, The effect of reducing dosage and catalyst cost, and controllable catalyst structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

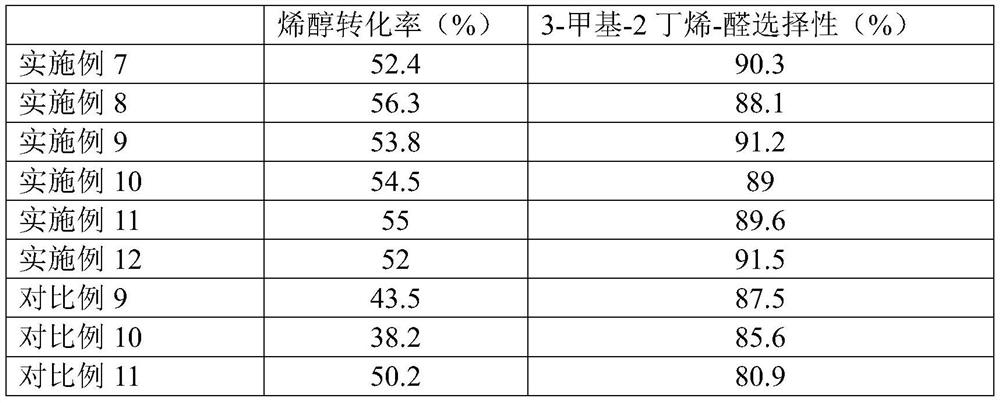

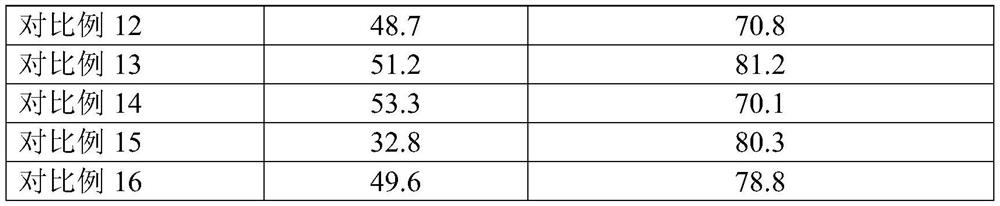

Examples

Embodiment 1

[0044] A preparation method of eggshell silver catalyst, the steps are:

[0045] 1) Dissolve 44g of silver nitrate in 50g of deionized water, then add 0.31g of magnesium nitrate and 0.05g of glycerol, and stir to obtain immersion solution 1; dissolve 20g of oxalic acid in 180g of deionized water, and stir to obtain dipping solution 2.

[0046] 2) Weigh 50g of α-alumina (spherical, with a diameter of 3mm and a specific surface area of 0.72m) 2 / g, pore volume 0.52mL / g, water absorption 50.2%, lateral pressure strength 130N / grain, α-alumina carrier purity 80wt%) placed in a round-bottomed flask, and the impregnation solution was introduced into the flask to soak the carrier, usually Press and soak for 60min, take out the carrier and drain to remove excess solution, vacuumize at 70°C to an absolute pressure of 6.67KPa for spin drying to obtain the first impregnated product.

[0047] 3) Place the first impregnation in a round-bottomed flask, evacuate to an absolute pressure of ...

Embodiment 2

[0050] A preparation method of an eggshell silver catalyst is different from Example 1 in that step 1) dissolves 150g of silver nitrate in 50g of deionized water, then adds 1.31g of potassium nitrate and 0.2g of glycerol, and stirs to obtain a dipping solution. Liquid 1: Dissolve 20 g of oxalic acid in 180 g of deionized water, and stir evenly to obtain impregnation liquid 2.

[0051] Finally, an eggshell-type silver catalyst with a silver loading of 24.7 wt%, a potassium content of 0.27% of the silver mass, an eggshell thickness of about 0.5 mm and good dispersibility was obtained.

Embodiment 3

[0053] A kind of preparation method of eggshell type silver catalyst, the difference with embodiment 1 is:

[0054] Step 1) Dissolve 44g of silver nitrate in 50g of deionized water, then add 0.31g of magnesium nitrate and 0.05g of polyethylene glycol, stir evenly to obtain dipping solution 1; dissolve 20g of oxalic acid in 80g of deionized water, stir evenly to obtain dipping solution two.

[0055] Finally, an eggshell-type silver catalyst with a silver loading of 15.2 wt%, a magnesium content of 0.17% of the silver mass, an eggshell thickness of about 0.6 mm and good dispersibility was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com