Protein adsorption material and preparation and application thereof

A technology for adsorbing materials and proteins, which is applied in the fields of analyzing materials, material inspection products, and material analysis by electromagnetic means. Effective separation, rapid capture and adsorption, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

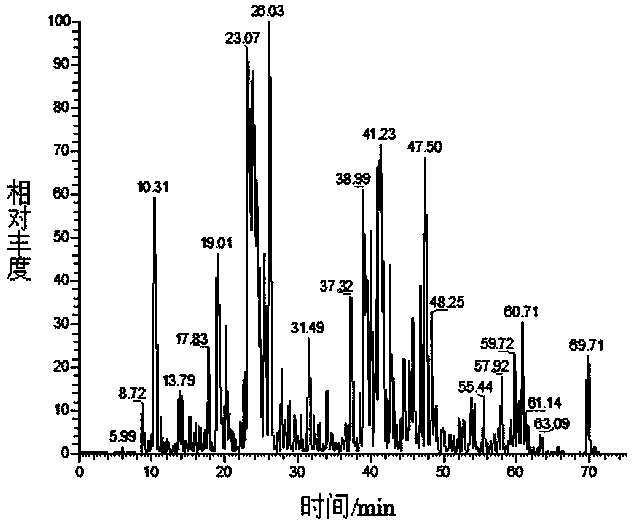

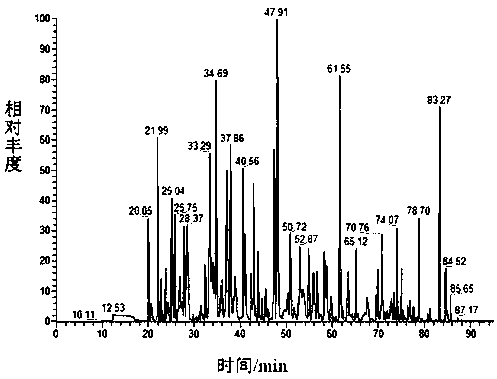

Image

Examples

Embodiment 1

[0030] 1. Modification of GO: Weigh 10mg GO, add 10mL water and ultrasonically disperse evenly without obvious deposition of insoluble matter, then dilute the obtained solution ten times with water to obtain a solution with a concentration of 0.1mg / mL; take 1mL solution for each portion , that is, 0.1 mg of GO, each added with 300 μL of 100 mg / mL PEI, shaken overnight at 25 ° C at a speed of 1400 rpm to ensure that there is no particle deposition;

[0031] 2. Introduction of Au: After the reaction of the above solution, centrifuge at 14000rpm for 15min to remove PEI that has not reacted on GO. After removing the supernatant, add 1mL water, 1μL 100mg / mL PEI, 4μL 100mg / mL HAuCl 4 , react in a water bath at 70°C for 1 h; after the reaction, centrifuge at 14,000 rpm for 15 min to remove the supernatant, then wash with water three times to remove unbonded Au;

[0032] 3. Introduction of polymeric spheres: Weigh 75mg of polymeric spheres, add 10mL of water to ultrasonically disperse...

Embodiment 2

[0034] Take 20 μL of Hela cell protein (concentration measured by BCA method: 2 mg / mL) extracted by 4% SDS, add 0.5 mL of 50 mM phosphate buffer (PB) with a pH of 8, mix well, add 5 μL of 1M TCEP, and React at 1500rpm in a shaker at 95°C for 10min. After cooling, place at room temperature, add 1mg of protein adsorption material PM@GO / PEI / Au (take 100μL from a solution with a concentration of 10mg / mL dissolved in water), mix well, and mix well at 40 Under ℃, 1000rpm shaking reaction 0.5h, then centrifuge at 14000rpm for 5min to remove the supernatant; wash the material 5 times with 50% methanol and 50mM phosphate buffer saline (PB) with a pH of 8, each wash is carried out at 14000rpm centrifugation conditions, Finally, add 100 μL of ammonium bicarbonate solution with a pH of 8 to the material to keep the whole system uniform, then add 1 μg of trypsin to the solution for enzymatic hydrolysis (37°C, 1000 rpm) for 12 hours, after the reaction is complete, centrifuge at 14000 rpm fo...

Embodiment 3

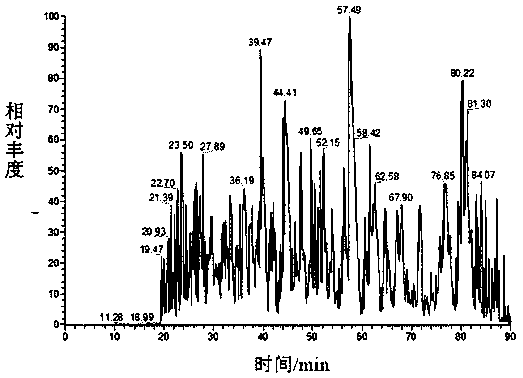

[0036]Weigh 1 mg of BSA, make a solution with a concentration of 1 mg / mL with 4% SDS, then take 20 μL, add 200 μL of 50 mM phosphate buffer (PB) with a pH of 8, and 5 μL of 1M DTT, cook at 95 ° C for 30 min, After cooling, add 0.5 mg of PM@GO / PEI / Au (1 mg / mL takes 500 μL), shake the reaction at 1000 rpm for 1 h at 25 ° C, then centrifuge at 14000 rpm for 5 min to remove the supernatant; use 80% methanol and 25 mM ammonium bicarbonate After washing the solution 5 times, add 200 μL of 50 mM ammonium bicarbonate solution with a pH of 8, add 0.8 μg trypsin at 37°C, oscillate at 1500 rpm for 12 hours, centrifuge at 10000 rpm for 3 minutes, take the supernatant, and wash the material with 80% ACN Afterwards, the supernatants were combined, freeze-dried and reconstituted, and analyzed by LC-MS. By matching the database, the sequence coverage rate of BSA was measured to be 82%. The result diagram is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com