Preparation method of neodymium oxide-doped composite film material

A composite film, neodymium oxide technology, applied in rare earth metal oxides/hydroxides, devices for coating liquids on surfaces, coatings, etc., to achieve the effects of small grain size, high crystallinity, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

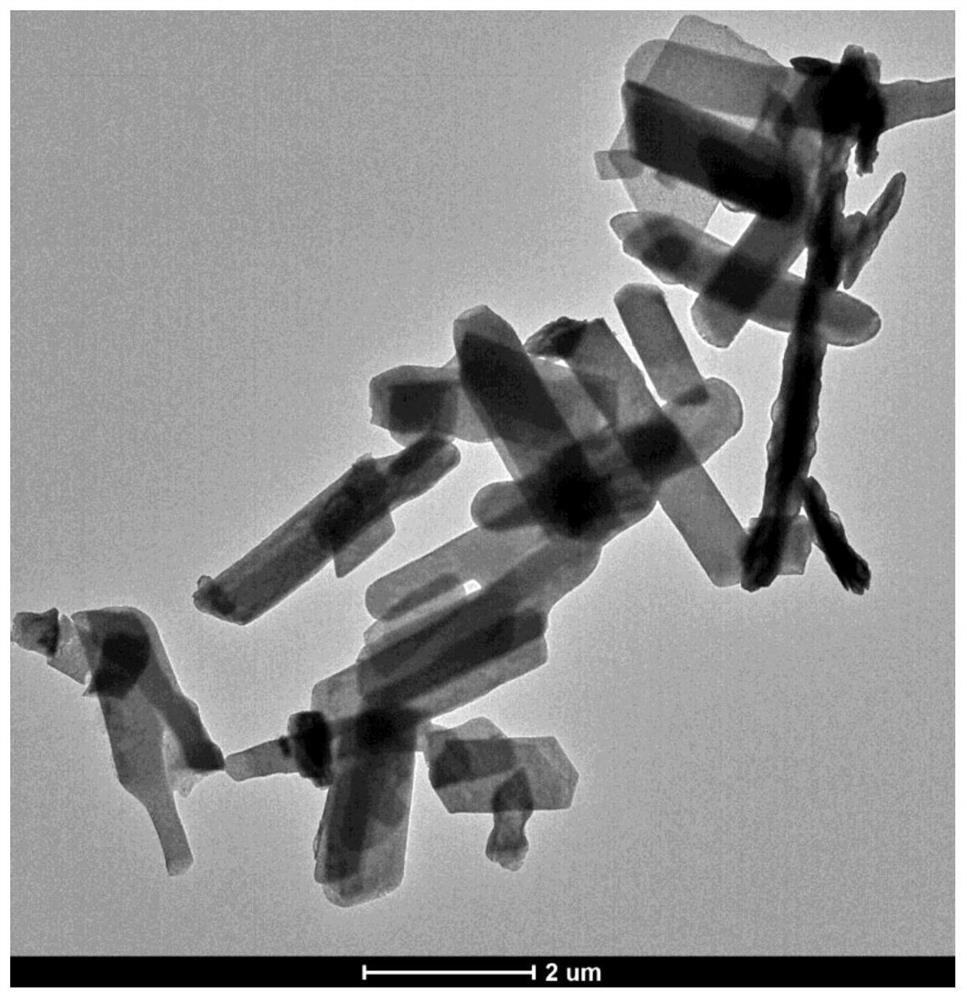

[0033] Firstly, neodymium oxide nanocrystals are prepared, and the specific steps include:

[0034] 1) Mix cyclohexane, neodymium nitrate aqueous solution, nonylphenol polyoxyethylene pentaether and nonylphenol polyoxyethylene nonather at a ratio of 16:5:2:1, and stir at room temperature for 1-1.5 hours to obtain a solution 1;

[0035] 2) Mix cyclohexane, oxalic acid aqueous solution, nonylphenol polyoxyethylene pentaether and nonylphenol polyoxyethylene nonather at a ratio of 16:5:2:1, and stir at room temperature for 1-1.5 hours to obtain solution 2;

[0036] 3) After mixing solution 1 and solution 2, place it at room temperature and stir for 10-20 minutes, then let it stand for 8-12 hours to obtain a mixed microemulsion;

[0037] 4) After the mixed microemulsion obtained in step (S3) is centrifuged at 9000 rpm for 30 minutes in a centrifuge, washed with absolute ethanol and dried to obtain neodymium oxalate powder;

Embodiment 2

[0048] Firstly, neodymium oxide nanocrystals are prepared, and the specific steps include:

[0049] 1) Mix cyclohexane, neodymium nitrate aqueous solution, nonylphenol polyoxyethylene pentaether and nonylphenol polyoxyethylene nonather at a ratio of 16:5:2:1, and stir at room temperature for 1-1.5 hours to obtain a solution 1;

[0050] 2) Mix cyclohexane, oxalic acid aqueous solution, nonylphenol polyoxyethylene pentaether and nonylphenol polyoxyethylene nonather at a ratio of 16:5:2:1, and stir at room temperature for 1-1.5 hours to obtain solution 2;

[0051] 3) After mixing solution 1 and solution 2, place it at room temperature and stir for 10-20 minutes, then let it stand for 8-12 hours to obtain a mixed microemulsion;

[0052] 4) After the mixed microemulsion obtained in step (S3) is centrifuged at 9000 rpm for 30 minutes in a centrifuge, washed with absolute ethanol and dried to obtain neodymium oxalate powder;

[0053] 5) Calcining the neodymium oxalate powder obtaine...

Embodiment 3

[0063] Firstly, neodymium oxide nanocrystals are prepared, and the specific steps include:

[0064] 1) Mix cyclohexane, neodymium nitrate aqueous solution, nonylphenol polyoxyethylene pentaether and nonylphenol polyoxyethylene nonather at a ratio of 16:5:2:1, and stir at room temperature for 1-1.5 hours to obtain a solution 1;

[0065] 2) Mix cyclohexane, oxalic acid aqueous solution, nonylphenol polyoxyethylene pentaether and nonylphenol polyoxyethylene nonather at a ratio of 16:5:2:1, and stir at room temperature for 1-1.5 hours to obtain solution 2;

[0066] 3) After mixing solution 1 and solution 2, place it at room temperature and stir for 10-20 minutes, then let it stand for 8-12 hours to obtain a mixed microemulsion;

[0067] 4) After the mixed microemulsion obtained in step (S3) is centrifuged at 9000 rpm for 30 minutes in a centrifuge, washed with absolute ethanol and dried to obtain neodymium oxalate powder;

[0068] 5) Calcining the neodymium oxalate powder obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com