Organic disintegrated sludge carbon source recycling method

A technology of organic sludge and sludge carbon, which is applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc. mud activity and other issues, to achieve the effect of reducing operating costs, achieving weight reduction, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

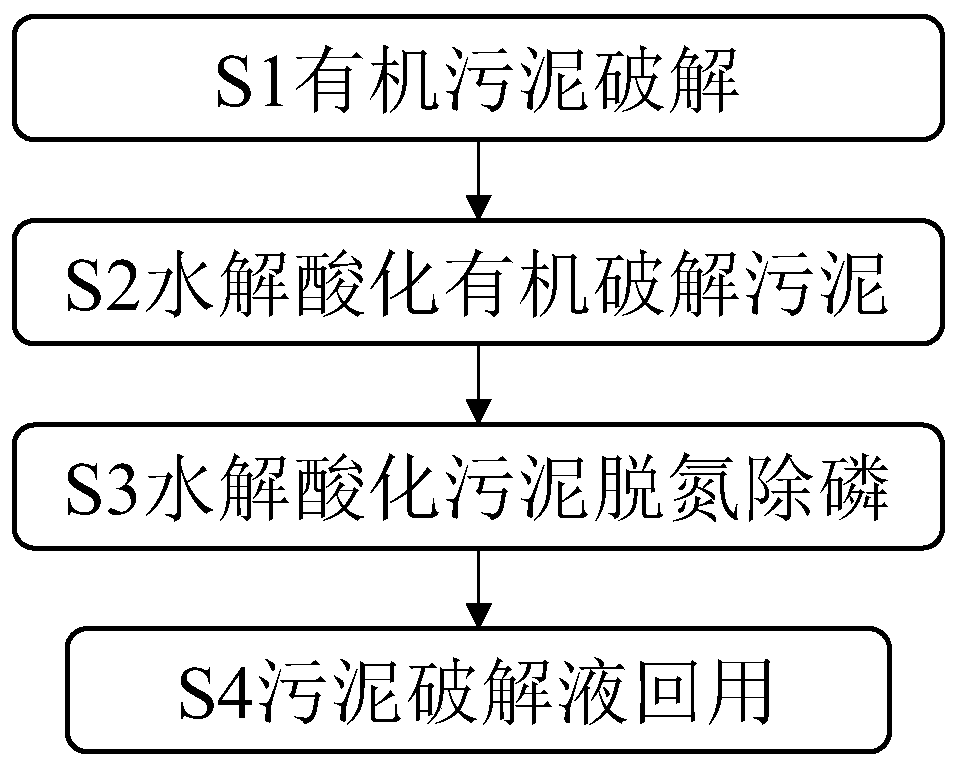

[0025] In this embodiment, the method for reusing organically decomposed sludge carbon sources comprises the following steps:

[0026] S1 Organic sludge cracking: The organic matter content of the organic sludge is 75%. The water content of the organic sludge is adjusted to 94% by using sewage. After adding lysozyme, perform high-pressure homogenization. The pressure of high-pressure homogenization is 35MPa, and the homogenization is performed once.

[0027] S2 hydrolyzed and acidified organic cracked sludge: Add 20 mg / g dry sludge of sodium persulfate and 12.8 mg / g dry sludge of ferrous sulfate to the organic cracked sludge obtained in S1, stir for 2 hours; inoculate and cultivate mature hydrolyzed acidified sludge Sludge, the inoculation amount is 1% of the volume of the organic decomposed sludge, continuously adjust the pH value of the sludge to 8, control the heating temperature to 45°C, and stir for 12 hours.

[0028] S3 denitrification and dephosphorization of hydrolyzed...

Embodiment 2

[0032] In this embodiment, the method for reusing organically decomposed sludge carbon sources comprises the following steps:

[0033] S1 Organic sludge cracking: The organic matter content of organic sludge is 75%, and the water content of organic sludge is adjusted to 92% by using sewage. After adding protease, perform high-pressure homogenization. The pressure of high-pressure homogenization is 60MPa, and homogenize once.

[0034] S2 Hydrolysis and acidification of organic decomposed sludge: add sodium persulfate 7mg / g dry sludge and calcium peroxide 12mg / g dry sludge to the organic decomposed sludge obtained in S1, stir for 1 hour; inoculate and cultivate mature hydrolyzed acidified sludge , the inoculation amount is 2% of the volume of the organic decomposed sludge, the pH value of the sludge is continuously adjusted to 6.5, the heating temperature is controlled at 50° C., and the stirring is carried out for 12 hours.

[0035] S3 hydrolysis and acidification sludge denitr...

Embodiment 3

[0039] In this embodiment, the method for reusing organically decomposed sludge carbon sources comprises the following steps:

[0040] S1 organic sludge cracking: the organic matter content of organic sludge is 75%, the water content of organic sludge is adjusted to 94% by sewage, and after adding protease and magnesium oxide 10mg / g dry sludge, perform high-pressure homogenization, and the pressure of high-pressure homogenization is 70MPa, homogenized once.

[0041] S2 hydrolyzed and acidified organic cracked sludge: Add 20 mg / g dry sludge of sodium persulfate and 12.8 mg / g dry sludge of ferrous sulfate to the organic cracked sludge obtained in S1, stir for 2 hours; inoculate and cultivate mature hydrolyzed acidified sludge Sludge, the inoculation amount is 1% of the volume of the organic decomposed sludge, continuously adjust the pH value of the sludge to 8, control the heating temperature to 45°C, and stir for 12 hours.

[0042] S3 denitrification and dephosphorization of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com