Piezoelectric MEMS ink-jet printing head and manufacturing method

An inkjet printing head and manufacturing method technology, applied in printing, inking devices, etc., can solve the problems of difficulty in ensuring the quality of the vibration plate, high potential risk of bonding, and many types of processes, so as to shorten the production cycle and improve the jetting performance , reducing the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

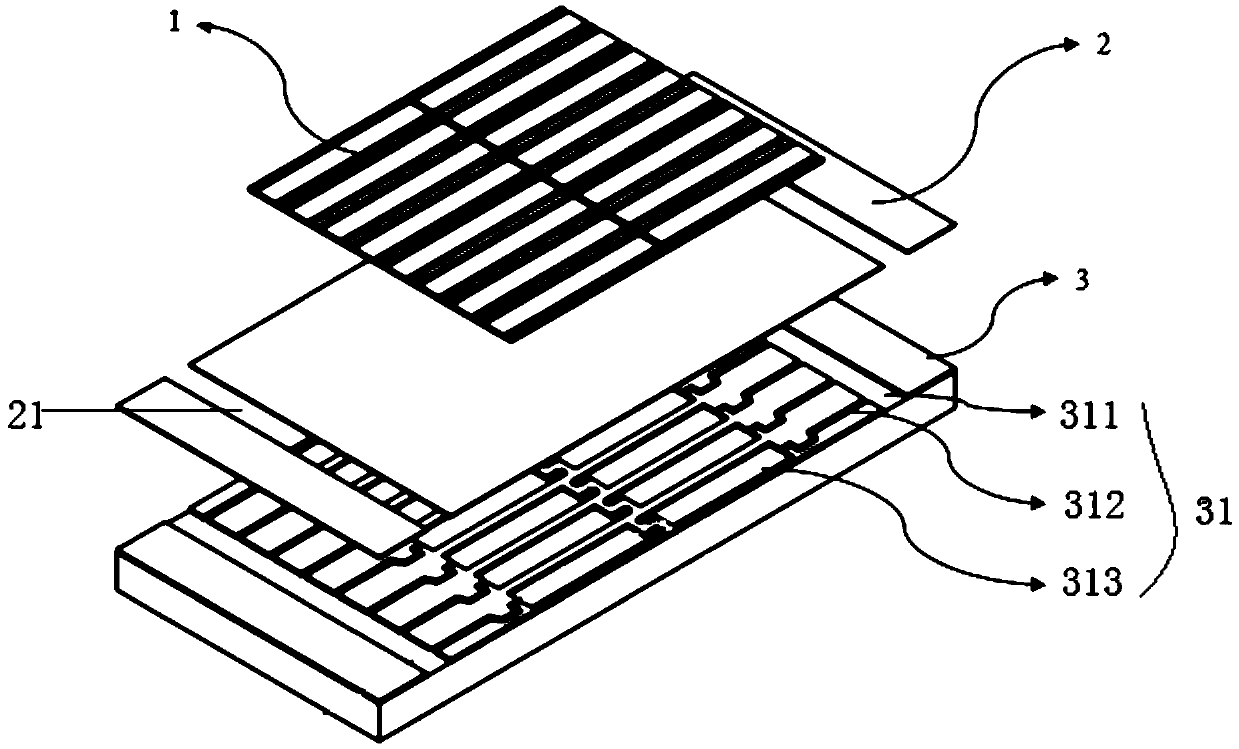

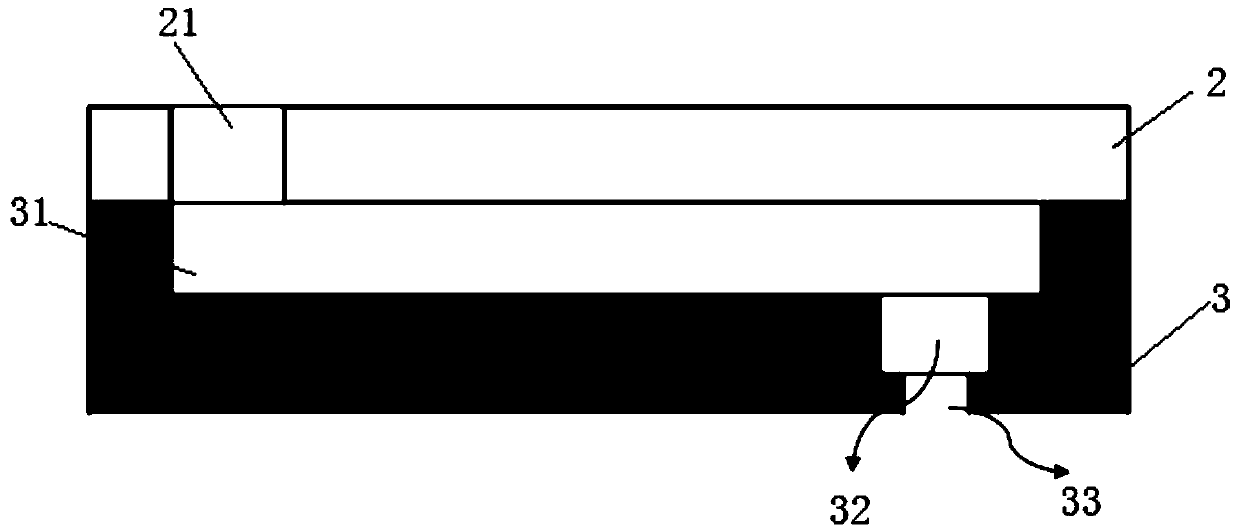

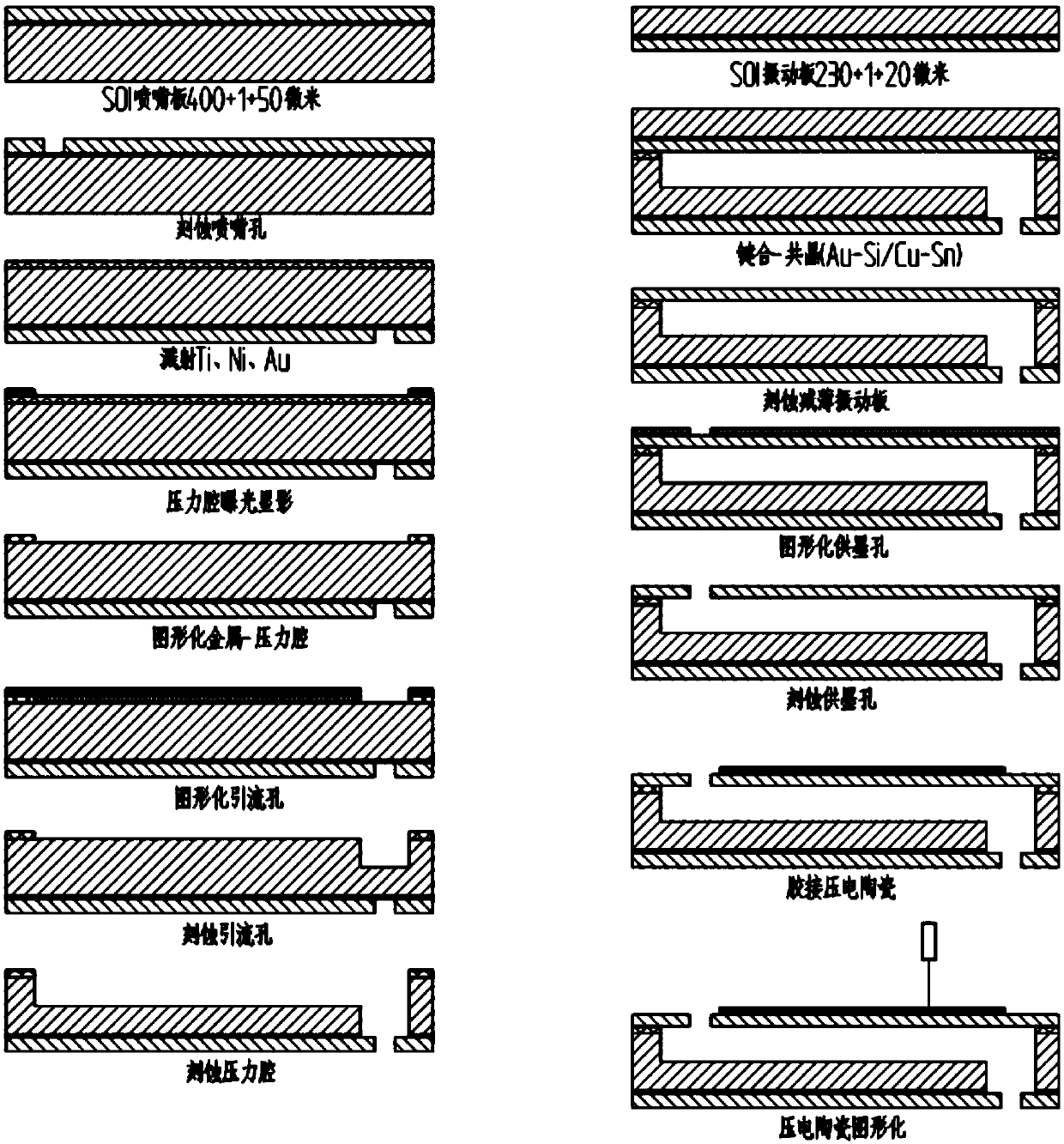

[0079] Such as figure 1 As shown, the piezoelectric inkjet printing head includes a piezoelectric ceramic layer 1, a vibrating plate 2, and a nozzle plate 3 from top to bottom, wherein both the vibrating plate 2 and the flow channel nozzle plate 3 are made of SOI silicon wafers. The vibration plate 2 is provided with an ink supply hole 21, and the nozzle plate 3 is provided with a pressure chamber 31, a drainage hole 32 and a nozzle hole 33 in sequence from top to bottom. The pressure chamber 31 includes two main ink channels arranged at the edge of the nozzle plate 3 311. Two groups of micro-channel structures arranged between the two main ink channels 311; the main ink channels 311 communicate with the ink supply holes 21, and each group of micro-channel structures includes connected filter channels 312 and flow channels 313, The filter c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com