Hydrate generation and sample preparation reaction kettle component

A technology for hydrate generation and sample preparation, applied in chemical/physical/physical-chemical mobile reactors, mixers, chemical/physical processes, etc. The effect of promoting heat transfer, ensuring uniformity and density, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

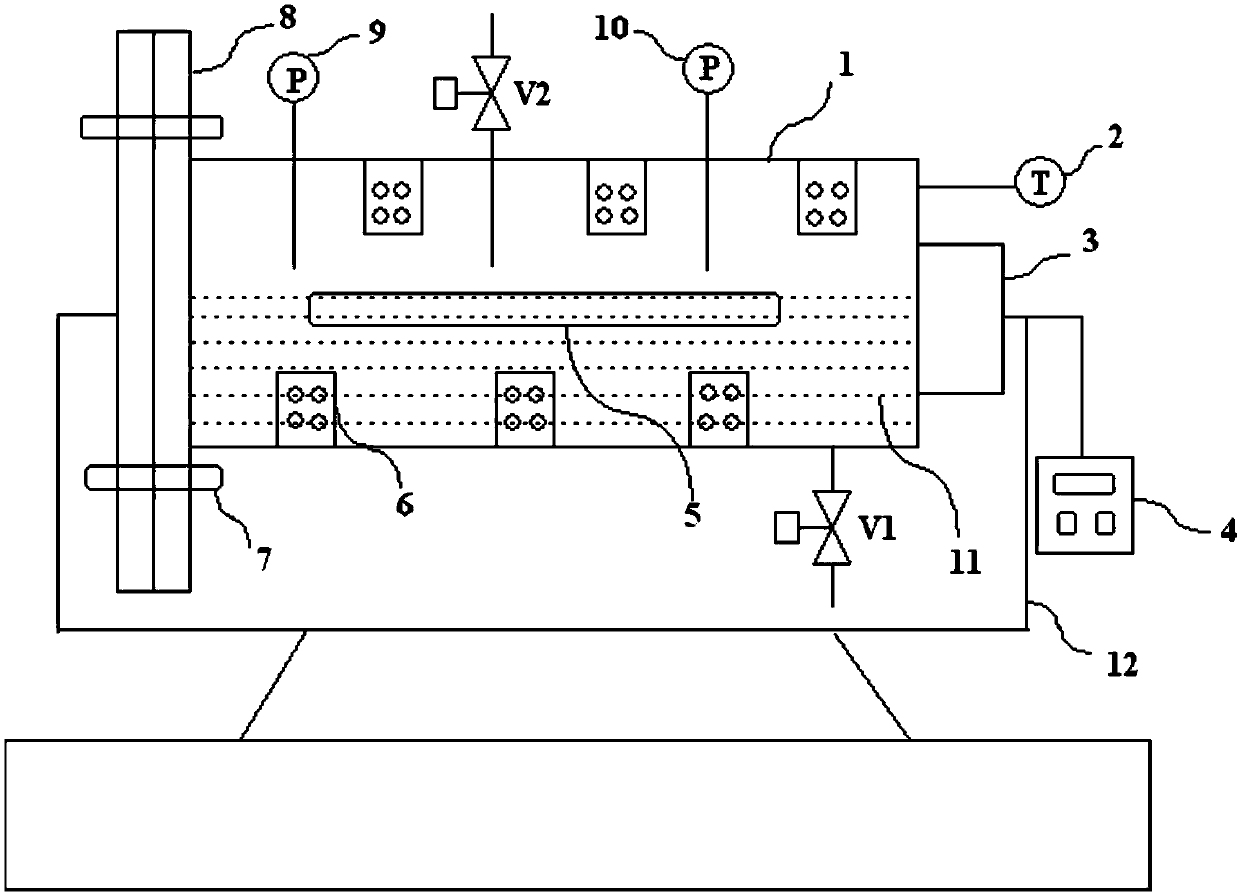

[0017] refer to figure 1 , is a component of hydrate formation and sample preparation reactor 1, including reactor 1, kettle cover 8, pressure and temperature monitoring device, and frequency-adjustable rotating motor; one side of reactor 1 is equipped with an air inlet pipe and an air inlet valve V2 , the other side is equipped with a liquid inlet pipe and a liquid inlet valve V1; the wall of the inlet pipe located inside the reactor 1 is densely covered with small holes; the inner and outer sides of the reactor 1 are coated with nano-titanium composite coating; the kettle cover 8 and The reaction kettle 1 is connected by a buckle, and the kettle cover 8 and the reaction kettle 1 are threaded and sealed by a rubber ring; the pressure and temperature monitoring device includes a pressure monitoring instrument 10 and a temperature monitoring instrument 2; The rotating forward and reverse rotating motor 3 and the motor frequency regulator 4 connected to it; the side wall of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com