Method for preparing large-area beta-phase indium selenide single crystal film

A single-crystal thin-film, large-area technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of impurity phase, low crystal quality, small film area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

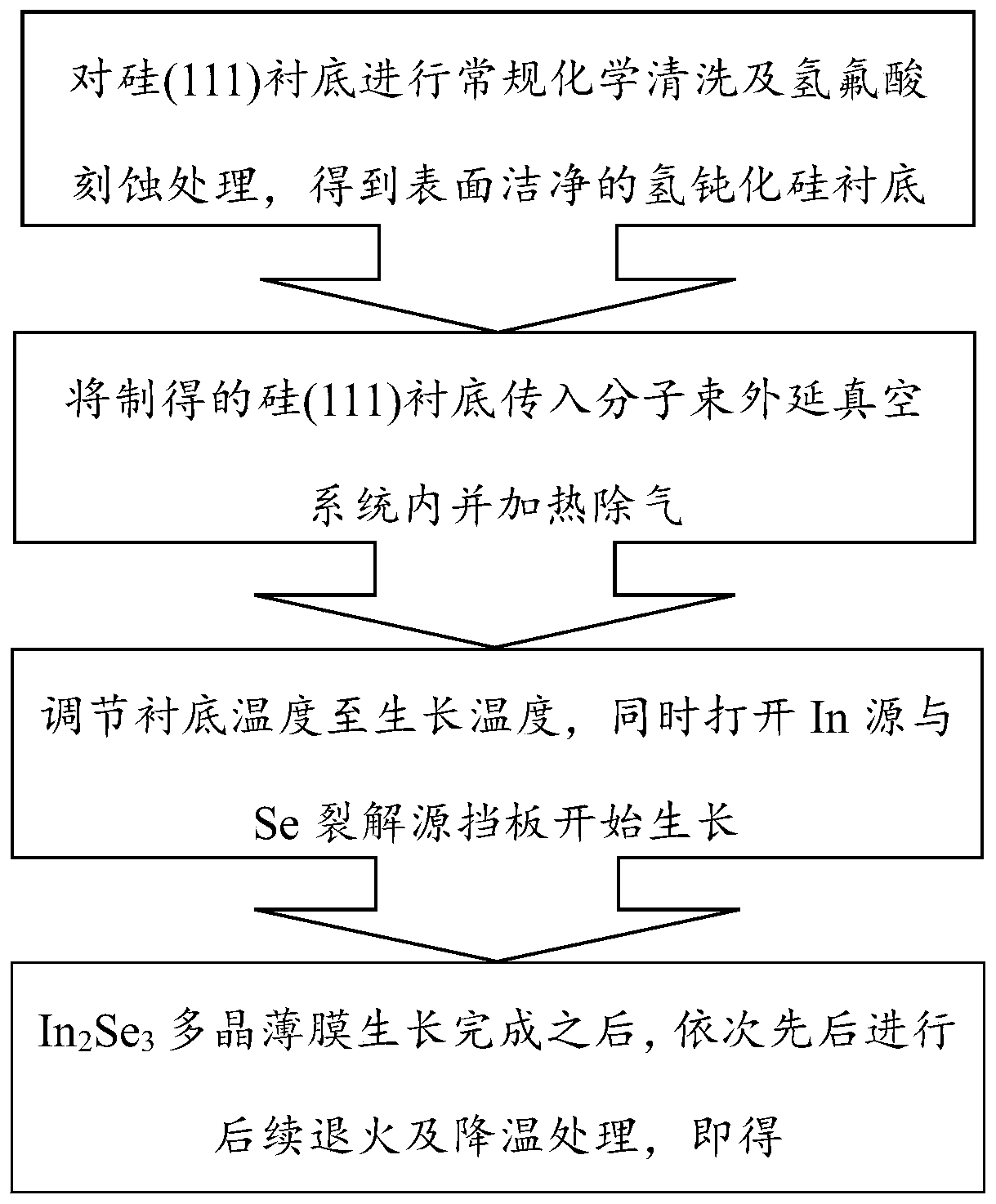

[0035] Such as figure 1 As shown, the present invention is a method for growing large-area high-quality β-phase single crystal In on a silicon substrate. 2 Se 3 The method for thin film specifically comprises the following steps:

[0036] 1): The silicon (111) substrate is placed before the ultra-high vacuum molecular beam epitaxy system, and the single crystal silicon substrate is chemically cleaned and chemically etched to obtain a flat silicon substrate with clean surface and hydrogen passivation. In the example, Acetone ultrasonic cleaning was performed for 3 minutes, alcohol ultrasonic cleaning was performed for 3 minutes, and ultrasonic cleaning was repeated for 3 rounds; then the substrate surface was chemically etched with 49% hydrofluoric acid solution for 1 minute.

[0037] 2): Put the silicon substrate prepared in step 1) into the molecular beam epitaxy vacuum system and heat it for degassing. When the maximum degassing temperature is 180°C, stop heating and degas...

Embodiment 2

[0049] The invention is a low-temperature growth of large-area single-crystal β-phase In on a silicon substrate. 2 Se 3 The method for thin film specifically comprises the following steps:

[0050] 1): Chemically clean the monocrystalline silicon (111) substrate and passivate the surface layer with hydrofluoric acid to obtain a flat silicon substrate with a clean surface. In the example, use acetone ultrasonic cleaning for 4 minutes, alcohol ultrasonic cleaning for 4 minutes, and repeat ultrasonic cleaning. Cleaning for 3 rounds; then corroding the substrate with a hydrogen fluoride reagent with a concentration of 49% for 2 minutes, then cleaning the residual chemical reagents on the surface with high-purity water, and then drying with high-purity nitrogen.

[0051] 2): Put the silicon substrate prepared in step 1) into the molecular beam epitaxy vacuum system and heat it for degassing. When the maximum degassing temperature is 180°C, stop heating and degas until the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com