Fingerprint acquisition device and manufacturing method thereof

A fingerprint collection and production method technology, applied in the direction of instruments, character and pattern recognition, computer components, etc., can solve the problems of high cost, thick modules, complex structure, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and beneficial effects of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Each embodiment in this specification is described in a progressive manner, each embodiment focuses on the difference from other embodiments, and the same or similar parts of each embodiment can be referred to each other.

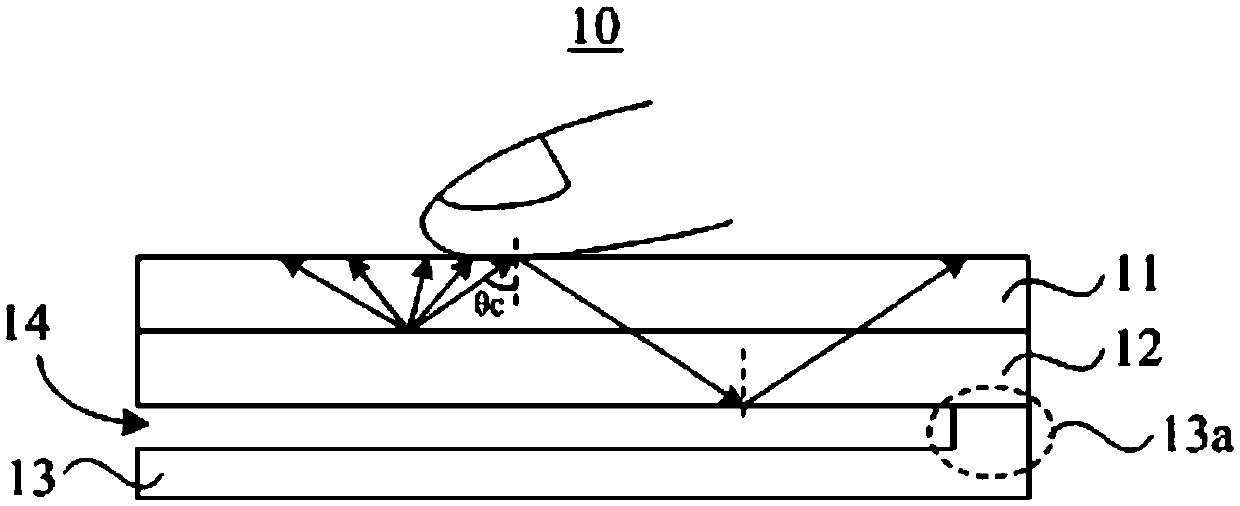

[0038] refer to figure 1 , figure 1 It is a schematic structural diagram of a fingerprint collection device 10 . The fingerprint collection device 10 is an off-screen optical fingerprint recognition technology that utilizes the total reflection imaging principle of physical optics to realize lightless collimation (for example: no lens). The fingerprint collection device 10 sequentially includes along its thickness direction: a light-transmitting cover plate 11 , a display layer 12 , and a sensing module 13 . Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com