Efficient boiling enhanced heat exchange tube and manufacturing method thereof

A heat exchange tube, high-efficiency technology, applied in the field of high-efficiency boiling enhanced heat exchange tubes and its production, can solve the problems of ignoring the characteristics of two-phase flow, destroying the development of the boundary layer, and high cost, achieving high economic value and market prospects, strengthening Energy transfer performance, effect of reducing heat exchanger area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

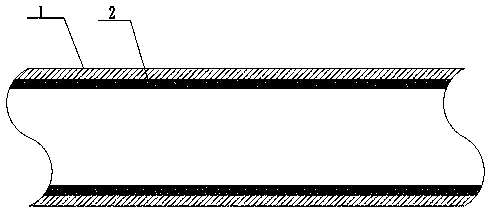

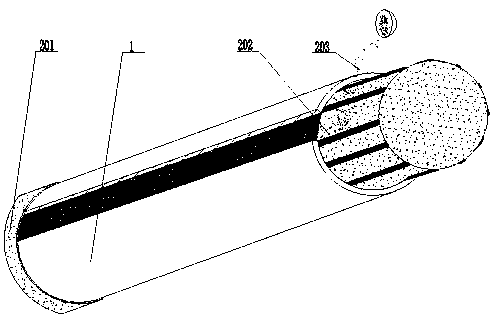

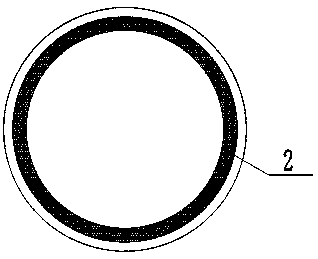

[0036] In this embodiment, the base tube is circular, and the inner diameter of the base tube is 20mm. First, a graphite rod abrasive tool is inserted into the base tube. It is equal to the inner diameter of the base tube. After the graphite rod abrasive tool and the base tube are fastened and installed, it can effectively avoid the leakage of the injected copper powder. There are several small grooves in the middle of the graphite rod abrasive tool. The space is divided into several subspaces, and copper particles of different particle sizes are filled according to the determined capillary gradient direction of the heterogeneous surface, and the particle diameter is gradually reduced along the opposite direction of gravity with a certain gradient for sintering to form the surface morphology of multi-scale heterogeneous copper particles, and then Pull out the partition plate, put it into the sintering furnace for sintering at 600°C, and put it into H 2 o 2Chemical oxidation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com