A dry-process antistatic spandex spinning oil and preparation method thereof

A technology of spinning oil agent and composite antistatic agent, which is applied in the direction of textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of poor antistatic performance, slow unwinding speed, poor unwinding performance, etc., and achieve good smoothness , ensuring stability and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

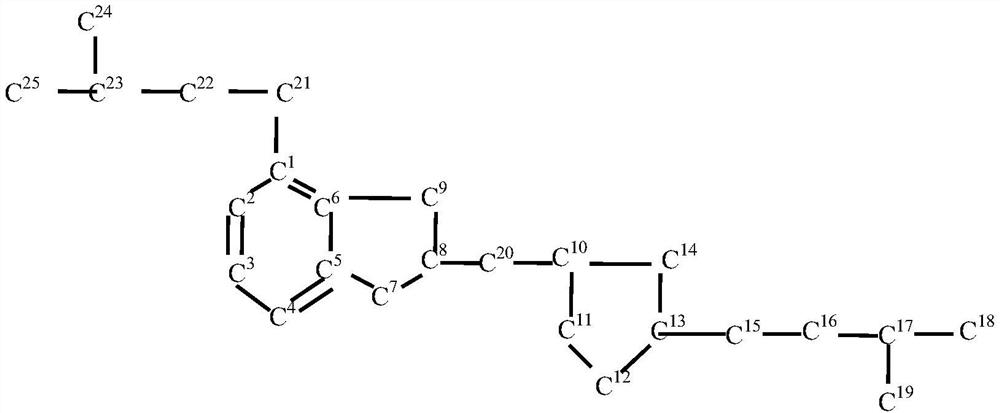

Method used

Image

Examples

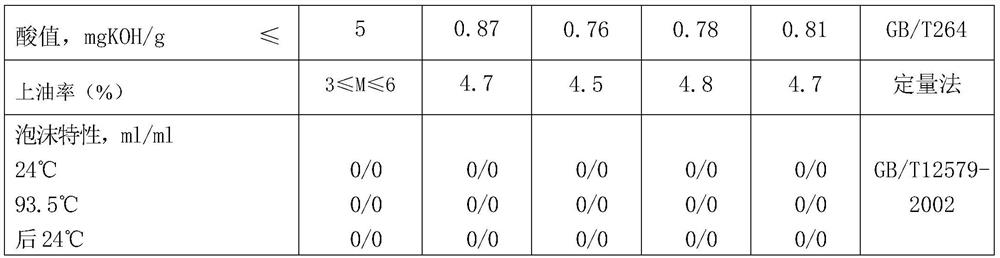

Embodiment 1

[0058]The present invention is a dry process antistatic spandex spinning oil, which is composed of a composite high temperature smoothing agent, a composite antistatic agent, a phenolic antioxidant, an aniline antioxidant, an alkene acid antioxidant, a high temperature dispersant, a softener, Environmentally friendly emulsifier, stearic acid metal salt, preservative and defoaming agent. In the dry antistatic spandex spinning oil, the weight percentage of the hydrogenated paraffin base oil is 51%, the weight percentage of the hydrogenated naphthenic base oil is 25%, and the weight percentage of the hydrogenated naphthenic base oil is 25%. The weight percentage of the methyl silicone oil is 8%, the weight percentage of the composite antistatic agent is 7%, the weight percentage of the phenolic antioxidant is 0.5%, and the weight percentage of the anilino antioxidant is 0.5%. The percentage is 0.5%, the weight percentage of the alkene acid antioxidant is 0.8%, the weight percenta...

Embodiment 2

[0074] The present invention is a dry process antistatic spandex spinning oil, which is composed of a composite high temperature smoothing agent, a composite antistatic agent, a phenolic antioxidant, an aniline antioxidant, an alkene acid antioxidant, a high temperature dispersant, a softener, Environmentally friendly emulsifier, stearic acid metal salt, preservative and defoaming agent. In the dry antistatic spandex spinning oil, the weight percentage of the hydrogenated paraffin base oil is 54%, the weight percentage of the hydrogenated naphthenic base oil is 21%, and the weight percentage of the hydrogenated naphthenic base oil is 21%. The weight percentage of the methyl silicone oil is 7%, the weight percentage of the composite antistatic agent is 8%, the weight percentage of the phenolic antioxidant is 0.6%, and the weight percentage of the anilino antioxidant is 0.6%. The percentage is 0.4%, the weight percentage of the alkenoic acid antioxidant is 0.3%, the weight perce...

Embodiment 3

[0090] The present invention is a dry process antistatic spandex spinning oil, which is composed of a composite high temperature smoothing agent, a composite antistatic agent, a phenolic antioxidant, an aniline antioxidant, an alkene acid antioxidant, a high temperature dispersant, a softener, Environmentally friendly emulsifier, stearic acid metal salt, preservative and defoaming agent. In the dry antistatic spandex spinning oil, the weight percentage of the hydrogenated paraffin base oil is 52%, the weight percentage of the hydrogenated naphthenic base oil is 22%, and the weight percentage of the hydrogenated naphthenic base oil is 22%. The weight percentage of the methyl silicone oil is 10%, the weight percentage of the composite antistatic agent is 6%, the weight percentage of the phenol-based antioxidant is 0.8%, and the weight percentage of the anilino antioxidant is 0.8%. The percentage is 0.3%, the weight percentage of the alkene acid antioxidant is 0.5%, the weight pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com