Mechanical cutting fluid high in stability

A technology of mechanical cutting and stability, applied in the petroleum industry, thickeners, additives, etc., can solve the problems of poor cooling and cleaning performance, weakened lubrication function, reduced cooling function, etc., to achieve excellent permeability and cleaning performance, Excellent lubricity and rust resistance, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

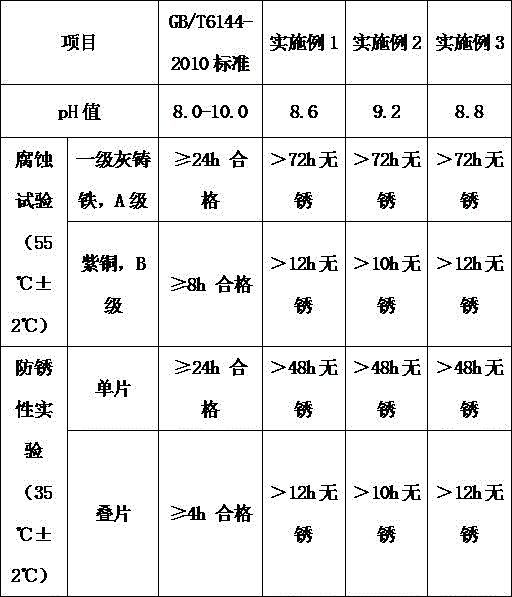

Examples

Embodiment 1

[0012] A kind of mechanical cutting fluid with better stability is made of the following raw materials in parts by weight: 20 parts of deionized water, 35 parts of sodium petroleum sulfonate, 20 parts of polyethylene glycol 400 monooleate, cocamidopropyl 3 parts of betaine, 2 parts of triethanolamine oleate, 2 parts of dibutyl sebacate, 2 parts of dicumyl peroxide, 0.5 parts of alkylphenol polyoxyethylene ether phosphate, 1 part of modified quartz powder, o 2 parts of phthalic acid, 0.5 part of potassium sorbate.

[0013] Wherein, the fineness of the modified quartz powder is 400 meshes; the modification method is: hydrolyze vinyltrimethoxysilane with acetic acid aqueous solution with a pH of 3.6, and add 1.42% of its weight in the quartz powder after hydrolysis; Vinyltrimethoxysilane was dispersed evenly with an ultrasonic dispersing device, and reacted in an oven at 120°C for 4.5 hours to obtain modified quartz powder.

[0014] A mechanical cutting fluid with good stability...

Embodiment 2

[0018] A kind of mechanical cutting fluid with better stability is made from the following raw materials in parts by weight: 30 parts of deionized water, 32 parts of sodium petroleum sulfonate, 16 parts of polyethylene glycol 400 monooleate, cocamidopropyl 3 parts of betaine, 2 parts of triethanolamine oleate, 1 part of dibutyl sebacate, 3 parts of dicumyl peroxide, 0.4 parts of alkylphenol polyoxyethylene ether phosphate, 0.9 parts of modified quartz powder, o 2 parts of phthalic acid, 0.7 parts of potassium sorbate.

Embodiment 3

[0020] A mechanical cutting fluid with good stability is made of the following raw materials in parts by weight: 40 parts of deionized water, 30 parts of sodium petroleum sulfonate, 15 parts of polyethylene glycol 400 monooleate, cocamidopropyl 3 parts of betaine, 2 parts of triethanolamine oleate, 2 parts of dibutyl sebacate, 2 parts of dicumyl peroxide, 0.4 parts of alkylphenol polyoxyethylene ether phosphate, 1.2 parts of modified quartz powder, o 1 part of phthalic acid, 0.4 part of potassium sorbate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com