Porous carbon modified waterborne polyurethane material and preparation method thereof

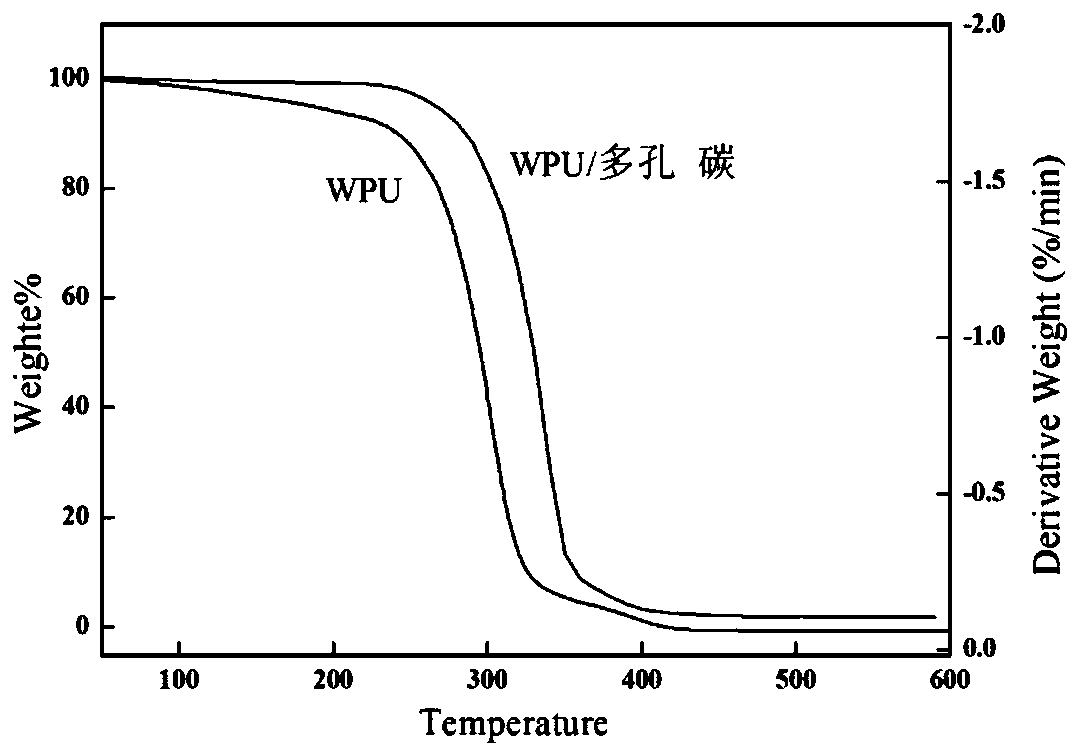

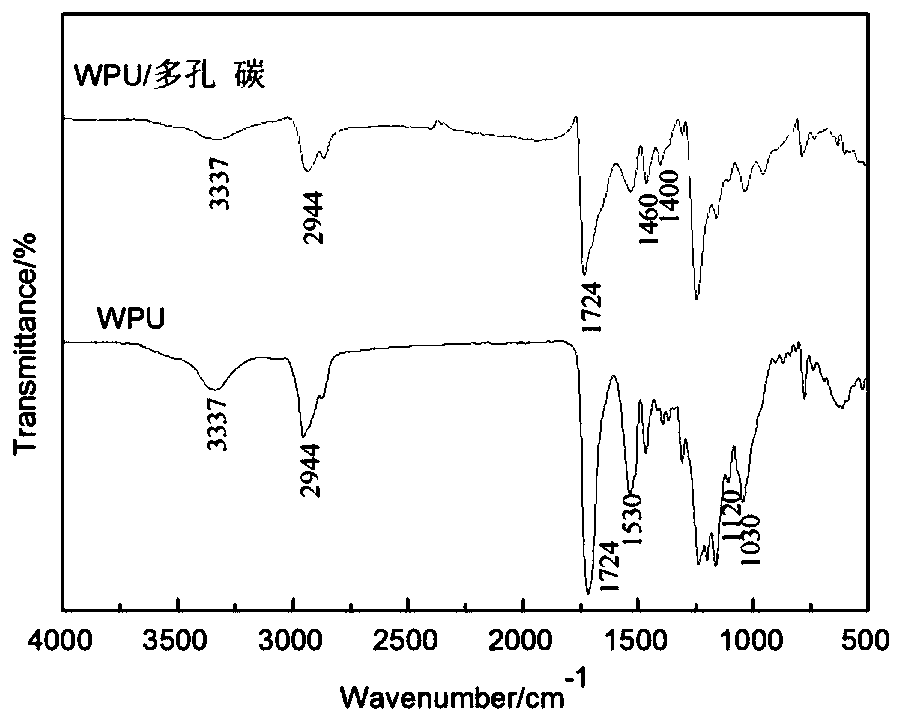

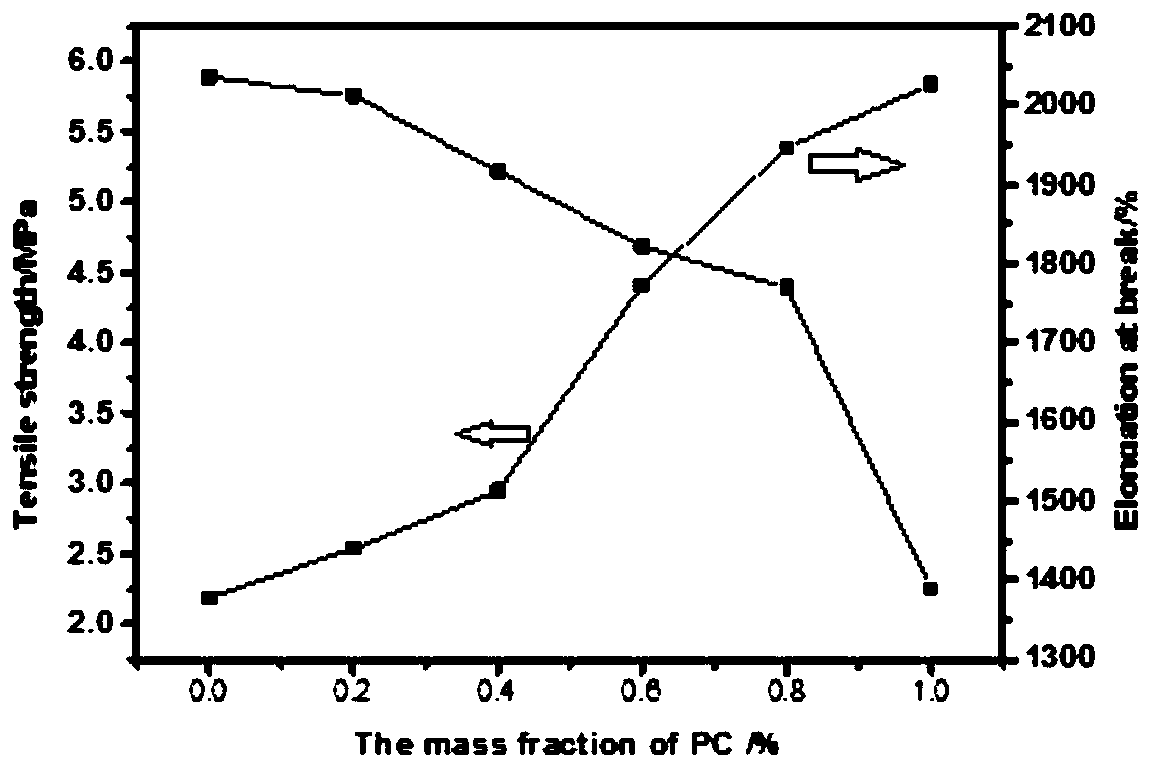

A technology of water-based polyurethane and porous carbon, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of poor thermal performance, mechanical properties and adsorption performance of water-based polyurethane, and achieve improved thermal stability and mechanical properties. The effects of stability and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 15.34g of polycaprolactone diol (PCL2000), 6.25g of isophore diisocyanate (IPDI), 1.0g of 2-2 dihydroxymethane into a 250mL three-necked flask equipped with a reflux condenser, a thermometer and an electric stirrer Propionic acid hydrophilic chain extender is dissolved in the solvent, and a small amount of catalyst dibutyltin dilaurate (DBTDL) is added, and the water bath is heated to 80°C for reaction. The reaction time is 2h; then add 0.5g trimethylolpropane , the reaction time is 1h; the temperature of the water bath is lowered to 40°C, then add 0.8g triethylamine, and react for 0.7h; finally add 64.77mL of water, disperse into the polymer under high-speed stirring, the reaction time is 1h, and finally get Waterborne polyurethane prepolymer (WPU).

[0038] Preparation of oxidized porous carbon: put 5g of porous carbon into a beaker, then add 90mL of sulfuric acid and 10mL of phosphoric acid, slowly add 25g of potassium permanganate while stirring in an ice-water ...

Embodiment 2

[0041] Add 14.84g polycaprolactone diol (PCL1000), 6.75g isophore diisocyanate (IPDI), 1.0g dimethylolpropionic acid to a 250mL three-necked flask equipped with a reflux condenser, a thermometer and an electric stirrer The hydrophilic chain extender is dissolved in the solvent, and a small amount of catalyst dibutyltin dilaurate (DBTDL) is added, and the water bath is heated to 75°C for reaction. The reaction time is 1h; then add 0.5g trimethylolpropane, and the reaction time is 2h; the temperature of the water bath was lowered to 40°C, then 0.8g of triethylamine was added, and reacted for 0.5h; finally, 65mL of water was added and dispersed into the polymer under high-speed stirring, and the reaction time was 1h, and finally a water-based polyurethane prepolymer was obtained. body.

[0042] Preparation of oxidized porous carbon: put 3g of porous carbon into a beaker, then add 30mL of sulfuric acid and 10mL of phosphoric acid, slowly add 10g of potassium permanganate while sti...

Embodiment 3

[0045] Add 10.8g of diphenylmethane diisocyanate and 17.5g of polycarbonate diol into a 250mL three-necked flask equipped with a reflux condenser, a thermometer, and an electric stirrer, and then add 3.0g of dimethylol butyric acid to make it hydrophilic The chain extender is dissolved in the solvent, and a small amount of catalyst dibutyltin dilaurate (DBTDL) is added, and the water bath is heated to 85°C for reaction, and the reaction time is 3h; then 0.5g of trimethylolpropane is added, and the reaction time is 1.5h The temperature of the water bath was lowered to 45°C, then 0.86g of triethylamine was added, and reacted for 1h; finally, 84.9mL of water was added, dispersed into the polymer under high-speed stirring, and the reaction time was 1h, and finally a waterborne polyurethane prepolymer was obtained.

[0046] Preparation of oxidized porous carbon: put 10g of porous carbon into a beaker, add 100mL of sulfuric acid and 15mL of phosphoric acid, slowly add 60g of potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com