Polyester resin for two-piece can printing ink, two-piece can printing ink and preparation method thereof

A technology of polyester resin and two-piece cans, applied in the field of polyester resin for two-piece can ink, two-piece can ink and its preparation, and ink field, which can solve poor transferability, poor scratch resistance, and two-piece can ink flying To solve the problem of serious ink and other problems, achieve the effect of obvious technical effect and good viscoelastic thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

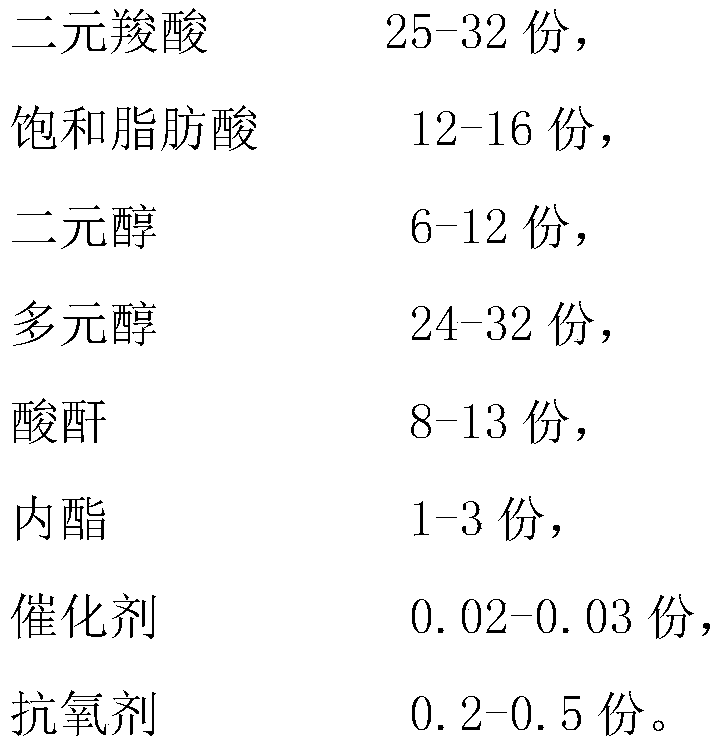

[0050] An embodiment of the present invention provides a method for preparing a polyester resin for two-piece cans, the method comprising:

[0051] Nitrogen, 25-32 parts of dicarboxylic acid, 12-16 parts of saturated fatty acid, 6-12 parts of dihydric alcohol, 24-32 parts of polyol, 8-13 parts of acid anhydride, 1-3 parts of lactone, catalyst 0.02 -0.03 parts, 0.2-0.5 parts of antioxidant and other materials were put into the reaction kettle, and the temperature was slowly raised to 130°C, and kept for 1H;

[0052] Raise the temperature to 148-152°C and keep it warm for 1H;

[0053] Raise the temperature to 158-162°C, divide the water by the water separator and keep it warm for 2 hours;

[0054] Raise the temperature to 168-172°C and keep it warm for 0.5H;

[0055] Raise the temperature to 178~182℃, keep it warm for 2H;

[0056] Raise the temperature to 188-192°C and keep it warm for 0.5H;

[0057] Raise the temperature to 198-200°C and keep it warm for 1H;

[0058] Raise t...

Embodiment 1

[0065] A method for preparing a polyester resin for two-piece cans, the method comprising:

[0066] Prepare polyester resin, each component weight percent content is as follows:

[0067] Isophthalic acid 29.67% Lauric acid 15.4% 2-Ethyl-2-butyl-1,3-propanediol 8.2% Trimethylolpropane 31.0% Phthalic anhydride 12.2% Caprolactone 3% Dibutyltin oxide 0.03% Butylated hydroxytoluene 0.5%

[0068] Nitrogen was passed, and all the materials in equal proportions were put into the reaction kettle, and the temperature was slowly raised to 130°C, and kept for 1H;

[0069] Raise the temperature to 148-152°C and keep it warm for 1H;

[0070] Raise the temperature to 158-162°C, divide the water by the water separator and keep it warm for 2 hours;

[0071] Raise the temperature to 168-172°C and keep it warm for 0.5H;

[0072] Raise the temperature to 178~182℃, keep it warm for 2H;

[0073] Raise the temperature to 188-192°C and keep ...

Embodiment 2

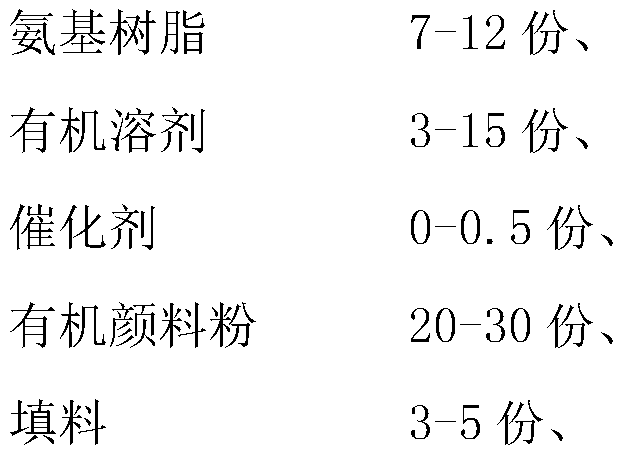

[0080] Prepare two cans of ink yellow primary color ink, and the weight percentage content of each component is as follows:

[0081] Polyester resin (made in embodiment 1) 45% Diethylene glycol monobutyl ether 4% Tripropylene glycol 8% Dispersant: sodium methylene bis-tetrasulfonate 3% fumed silica 2% C.I. Pigment Yellow 83 25% amino resin 12% p-Toluenesulfonic acid 1%

[0082] The preparation method is as follows: mix polyester resin (prepared in Example 2), diethylene glycol monobutyl ether, tripropylene glycol, wetting and dispersing agent, and amino resin, stir at high speed with a stirrer until the temperature of the mixture reaches 60°C, and then Add C.I. Pigment Yellow 83 and fumed silica while stirring, and then stir at high speed for 30 minutes after adding. Then pass through a three-roll mill to grind fineness. When the fineness is less than 5 μm, add p-toluenesulfonic acid catalyst and stir evenly. Then test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com