Resin for two-piece can white ink, and two-piece can white ink and preparation method thereof

A two-piece can, white ink technology, used in applications, inks, household appliances, etc., can solve the problems of paste, poor dot restoration, etc., achieve good acid resistance, improve coverage and transfer, and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a kind of preparation method of resin for two-piece can white ink, specifically comprises the following steps:

[0048] Weigh saturated fatty acid, trimethylolpropane, phthalic anhydride, neopentyl glycol, glycol, isophthalic acid, antioxidant, catalyst, xylene,

[0049] Nitrogen is passed through the reaction kettle, then xylene, neopentyl glycol, trimethylolpropane and saturated fat are added into the reaction kettle, and heated to 75-85°C;

[0050] Then add phthalic anhydride, dibasic alcohol, isophthalic acid, antioxidant in turn under stirring, and then add the catalyst;

[0051] Raise the temperature to 148-152°C and keep it warm for 1H;

[0052] Heating up to 158~162℃, reflux with water for 2H;

[0053] Raise the temperature to 168-172°C and keep it warm for 0.5H;

[0054] Raise the temperature to 178~182℃, keep it warm for 2H;

[0055] Raise the temperature to 198-202°C and keep it warm for 1H;

[0056] When the system is carried out ...

Embodiment 1

[0061] The preparation method of hydroxyl short oil alkyd resin is as follows:

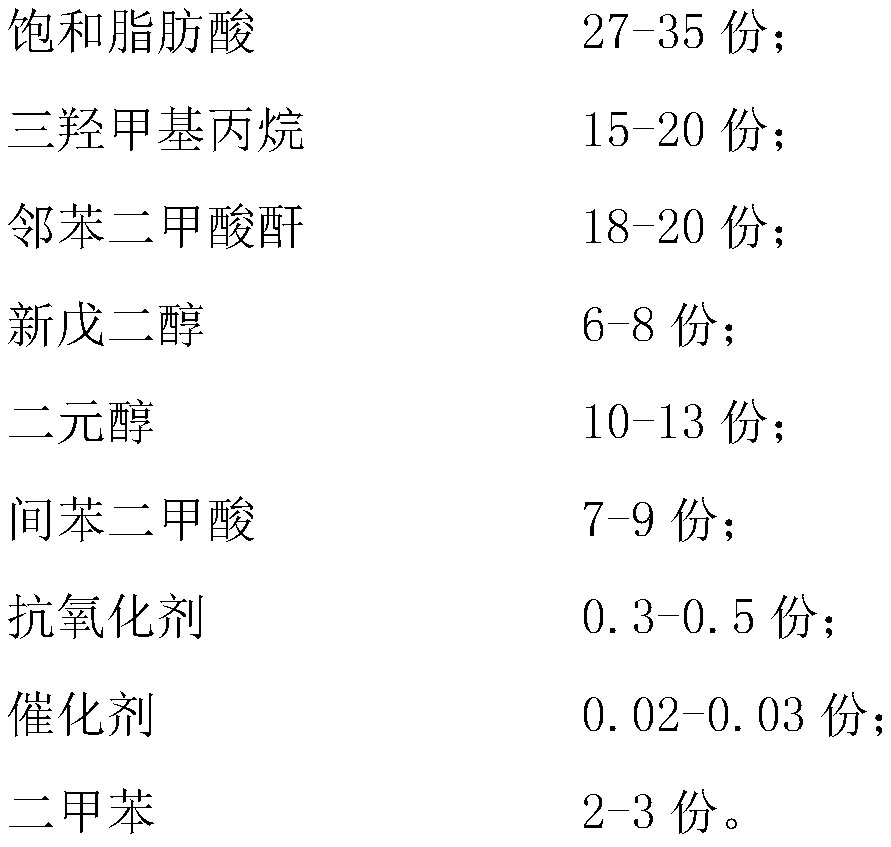

[0062] Prepare hydroxyl short oil alkyd resin, each component weight percent content is as follows:

[0063]

[0064]

[0065] Nitrogen is passed, then xylene, neopentyl glycol, trimethylolpropane, and coconut oil fatty acid are added to the reaction kettle, and heated to 75-85°C;

[0066] Then add phthalic anhydride, diethylene glycol, isophthalic acid, dibutyl hydroxytoluene in turn under stirring, and then add dibutyltin oxide;

[0067] Raise the temperature to 148-152°C and keep it warm for 1H;

[0068] Heating up to 158~162℃, reflux with water for 2H;

[0069] Raise the temperature to 168-172°C and keep it warm for 0.5H;

[0070] Raise the temperature to 178~182℃, keep it warm for 2H;

[0071] Raise the temperature to 198-202°C and keep it warm for 1H;

[0072] When the system is carried out without water, take a sample to measure the acid value ≤ 25mgKOH / g, and stop the reaction; ...

Embodiment 2

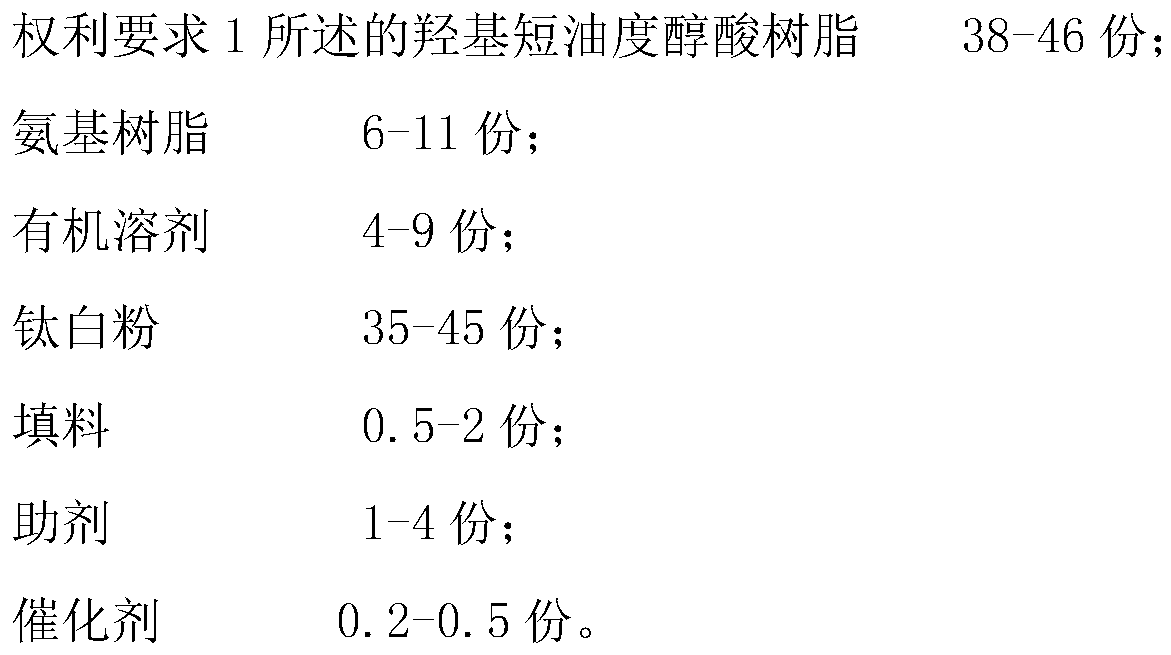

[0077] The present invention provides a method for preparing two-piece can white ink based on the special-purpose hydroxyl short oil alkyd resin of Example 1, and the weight percentage content of each component is as follows:

[0078]

[0079]

[0080] The preparation method is as follows:

[0081] Add hydroxyl short-oil alkyd resin (prepared in Example 1), amino resin, organic solvent, and additives into the stirring pot, stir evenly, and then add titanium dioxide and filler while stirring. Stir for another 30 minutes after adding the solid material, and then grind with a three-roll machine. Grind repeatedly four times first, and check the fineness. When the fineness is less than 3 μm, stop grinding; if it is greater than 3 μm, continue grinding until the detection is less than 3 μm. If the fineness is qualified, then add the catalyst to the ink and stir it evenly with a stirrer. Then test the viscosity, splash, hue, and dryness, and pack it after passing the test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com