Fiber preform with double wave-transparent ceramic coating layer and preparation method of fiber preform

A technology of ceramic coating and prefabricated body is applied in the field of preparation of high-temperature electromagnetic wave-transmitting composite materials, which can solve the problems of oxidation, limited temperature resistance of quartz fiber, easy moisture absorption of boron nitride coating, etc. The effect of improving poor oxidation resistance and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

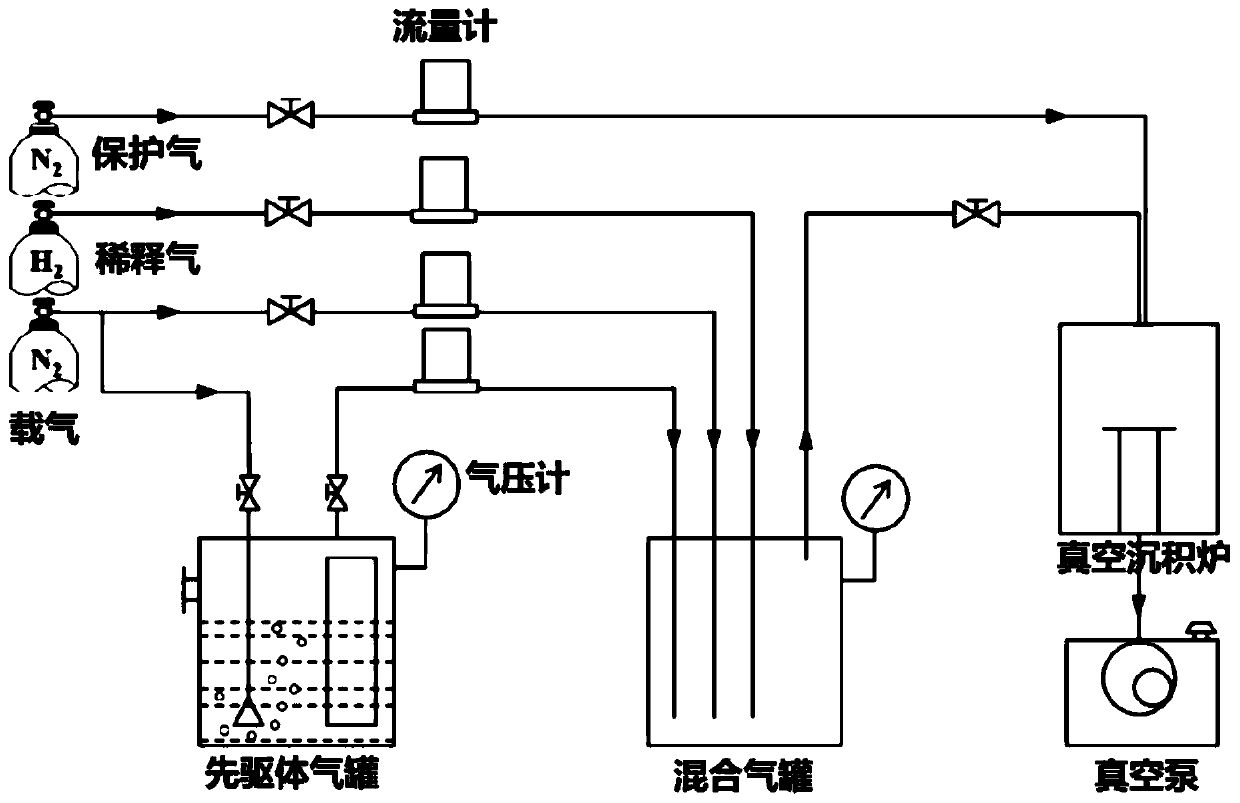

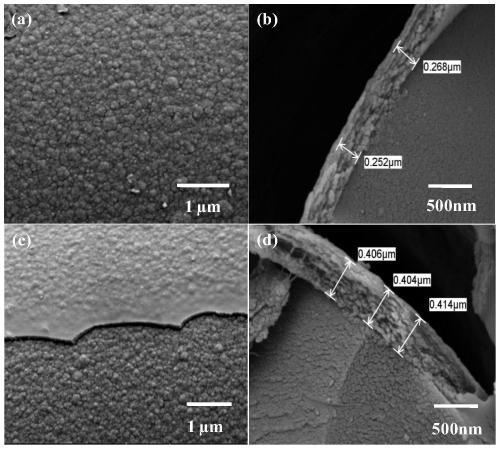

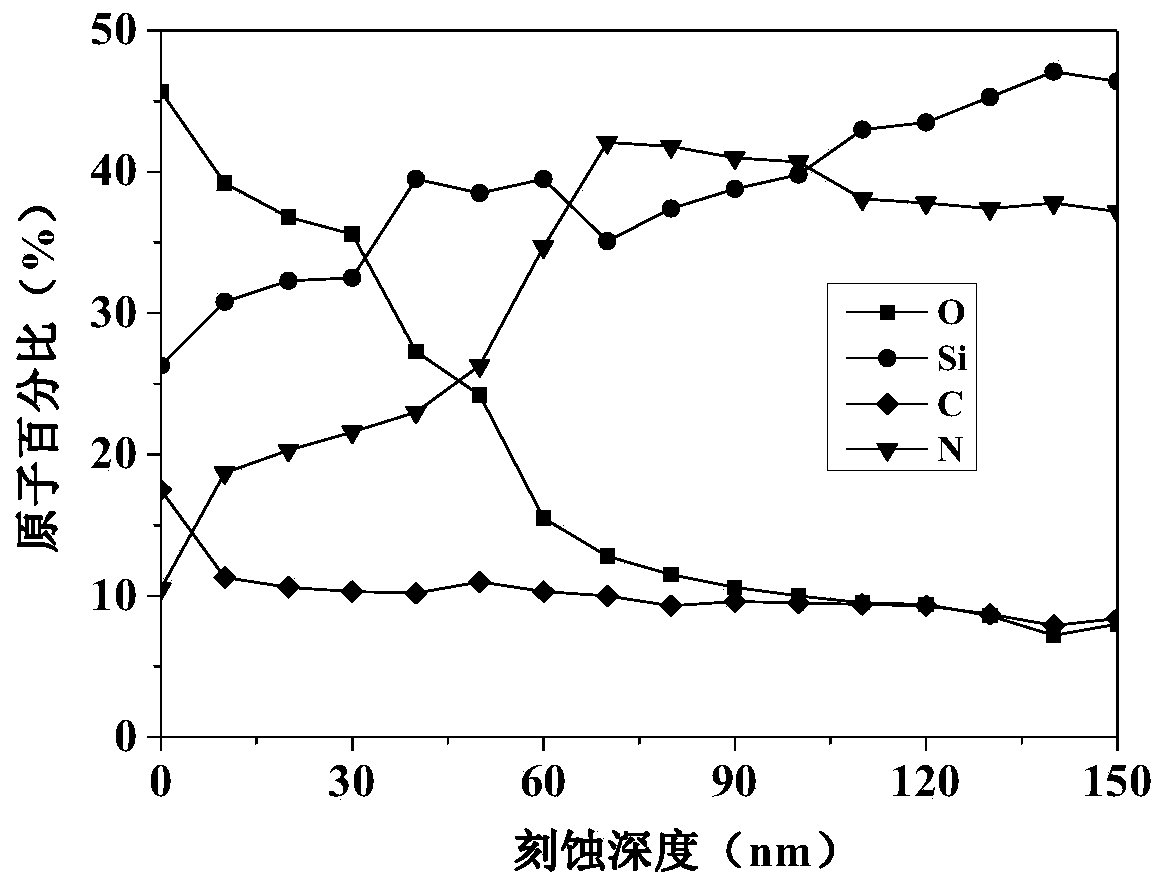

[0043] A method for preparing a fiber preform with a double transparent wave ceramic coating in this embodiment comprises the following steps:

[0044] (1) Put the silicon nitride fiber into the deposition furnace, heat it to 1100°C at a heating rate of 10°C / min under the protection of nitrogen atmosphere, then vacuumize, and use the carrier gas and diluent gas (both nitrogen) to move the precursor The liquid borazine (concentration is 3.1vol.%) is brought into the deposition furnace; at the same time, adjust the working state of the vacuum pump to keep it in balance with the flow rate of the carrier gas to achieve the pressure required for deposition and keep it stable. When stable, the corresponding The flow rate of the carrier gas is 0.2L / min, the flow rate of the dilution gas is 1.0L / min, the pressure of the precursor gas tank is 0.16MPa, the pressure of the mixing tank is 0.3MPa, and the deposition time is 60min. After the deposition is completed, turn off the carrier gas ...

Embodiment 2

[0056] A method for preparing a fiber preform with a double transparent wave ceramic coating in this embodiment comprises the following steps:

[0057] (1) Put the silicon nitride fiber into the deposition furnace, heat it to 1300°C at a heating rate of 10°C / min under the protection of nitrogen atmosphere, then vacuumize, and use the carrier gas and dilution gas (both nitrogen) to move the precursor The liquid borazine (concentration is 3.1vol.%) is brought into the deposition chamber; at the same time, adjust the working state of the vacuum pump to keep it in balance with the flow rate of the carrier gas to achieve the pressure required for deposition and keep it stable. When stable, the corresponding The flow rate of the carrier gas is 0.2L / min, the flow rate of the dilution gas is 1.0L / min, the pressure of the precursor gas tank is 0.16MPa, the pressure of the mixing tank is 0.3MPa, and the deposition time is 30min. After the deposition is completed, turn off the carrier gas...

Embodiment 3

[0061] A method for preparing a fiber preform with a double transparent wave ceramic coating in this embodiment comprises the following steps:

[0062](1) Put the silicon nitride fiber into the deposition furnace, heat it to 1200°C at a heating rate of 10°C / min under the protection of nitrogen atmosphere, then vacuumize, and use the carrier gas and diluent gas (both nitrogen) to move the precursor to 1200°C. The liquid borazine (concentration is 3.1vol.%) is brought into the deposition chamber; at the same time, adjust the working state of the vacuum pump to keep it in balance with the flow rate of the carrier gas to achieve the pressure required for deposition and keep it stable. When stable, the corresponding The flow rate of the carrier gas is 0.6L / min, the flow rate of the dilution gas is 1.3L / min, the pressure of the precursor gas tank is 0.16MPa, the pressure of the mixing tank is 0.3MPa, and the deposition time is 60min. After the deposition is completed, turn off the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com