Ceramic slurry having high firing finished product rate and used for grouting and preparation method thereof

A technology for finished products and mud, which is applied in the field of ceramic mud for grouting with high firing yield and its preparation field, can solve the problems of uneven structure distribution, low firing power, complex product shape, etc., and achieves guaranteed carbonization. Silicon particle size, high melting point, and the effect of reducing the amount of quartz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

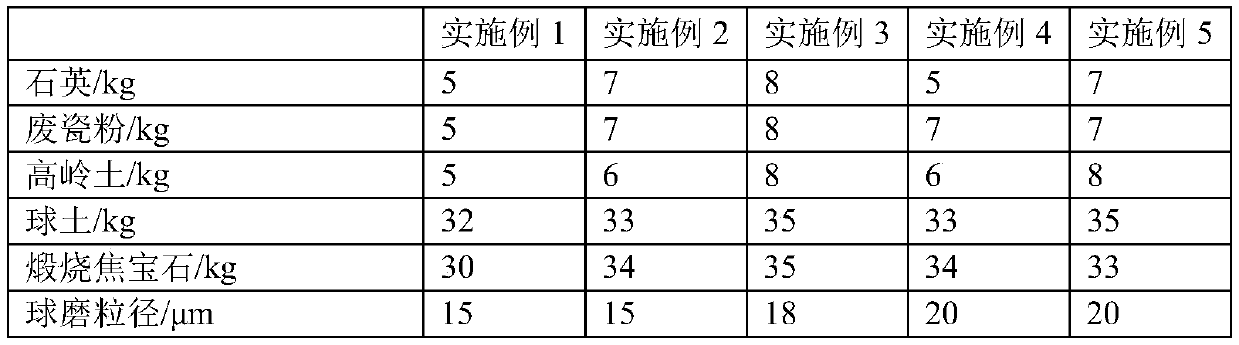

[0048] A method for preparing ceramic slurry for grouting with a high firing rate, comprising the following steps,

[0049] S1: 5 parts of quartz, 5 parts of waste porcelain powder, 5 parts of kaolin, 32 parts of ball clay, 30 parts of calcined coke gemstones, and 28 parts of water are mixed and ball-milled to obtain rough grinding mud;

[0050] S2: keep stirring the coarse grinding mud, and carry out aging. The aging time is 3 days. During the aging period, the coarse grinding mud is replenished with water according to the water evaporation of the coarse grinding mud, so as to keep the volume of the mud stable;

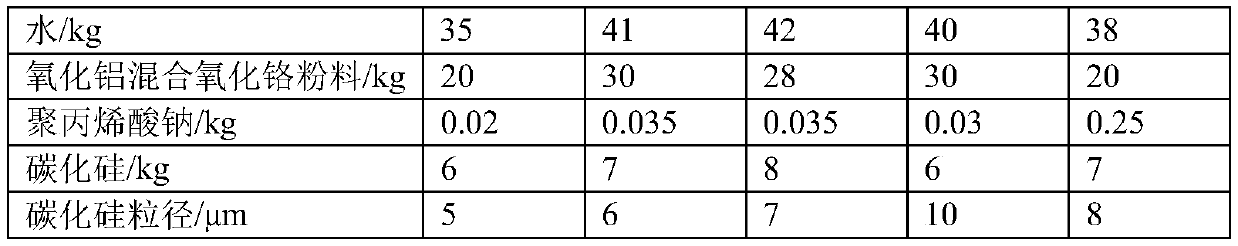

[0051] S3: Before grouting, add 20 parts of alumina mixed with chromium oxide powder, stir for 3 hours, add 0.02 parts of sodium polyacrylate, continue stirring for 1 hour, then add 6 parts of silicon carbide, and stir for 1 hour to obtain ceramic slurry for grouting.

[0052] Here, quartz, waste porcelain powder, kaolin, ball clay, and calcined coke are all powder m...

Embodiment 6

[0087] A preparation method of ceramic slurry for grouting with a high firing rate, based on Example 1, comprising the following steps, S1: 5 parts of quartz, 5 parts of waste porcelain powder, 5 parts of kaolin, and 32 parts of ball clay , 30 parts of calcined coke gemstones, 28 parts of water raw materials are mixed and ball milled to obtain rough grinding mud;

[0088] S2: keep stirring the coarse grinding mud, and carry out aging. The aging time is 3 days. During the aging period, the coarse grinding mud is replenished with water according to the water evaporation of the coarse grinding mud, so as to keep the volume of the mud stable;

[0089] S3: Before grouting, add 20 parts of alumina mixed with chromium oxide powder, stir for 4 hours, then add 6 parts of silicon carbide, stir for 1 hour, and obtain ceramic slurry for grouting.

Embodiment 7

[0091] A preparation method of ceramic slurry for grouting with a high firing rate, based on Example 1, comprising the following steps, S1: 5 parts of quartz, 5 parts of waste porcelain powder, 5 parts of kaolin, and 32 parts of ball clay , 30 parts of calcined coke gemstones, 28 parts of water raw materials are mixed and ball milled to obtain rough grinding mud;

[0092] S2: keep stirring the coarse grinding mud, and carry out aging. The aging time is 3 days. During the aging period, the coarse grinding mud is replenished with water according to the water evaporation of the coarse grinding mud, so as to keep the volume of the mud stable;

[0093] S3: Before grouting, add 20 parts of alumina mixed with chromium oxide powder, 0.02 part of sodium polyacrylate, and 6 parts of silicon carbide, and stir for 5 hours to obtain ceramic slurry for grouting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com