Chemical waste gas spraying and washing treatment tower

A technology for treating towers and exhaust gas, which is applied in gas treatment, chemical instruments and methods, and dispersed particle filtration, etc. It can solve problems such as inability to prescribe the right medicine, complex physical and chemical properties, and human health effects, so as to achieve better treatment effect and increase By area, the effect of increasing the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

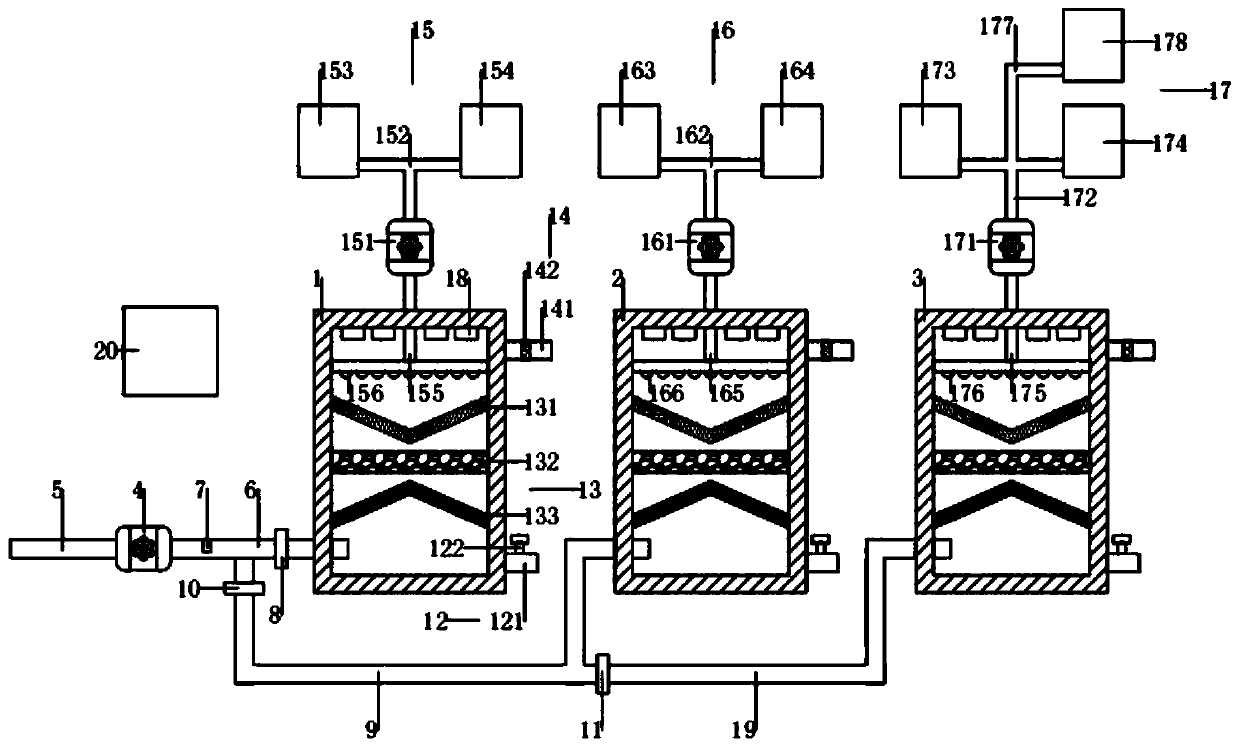

[0031] see figure 1, a chemical waste gas spray washing treatment tower, including the first treatment tower 1, the second treatment tower 2, the third treatment tower 3 and PLC controller 20, the first treatment tower 1, the second treatment tower 2 and the third treatment tower The lower right end of the tower 3 is provided with a third electromagnetic valve 12, the upper right end of the first processing tower 1, the second processing tower 2 and the third processing tower 3 are all provided with a particle filter layer 14, the left side of the first processing tower 1 An air pump 4 is provided, and the air pump 4 is electrically connected to the PLC controller 20. The suction port of the air pump 4 is fixed with a suction pipe 5, and the exhaust port of the air pump 4 is fixed with a first exhaust pipe 6, and the first exhaust pipe 6 The other end extends into the first treatment tower 1, the inner wall of the first exhaust pipe 6 is fixed with a pH sensor 7, and the pH se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com