Soybean oligopeptide powder and preparation method thereof

A soybean oligopeptide and powder technology, applied in food science and other directions, can solve problems such as low health care function, achieve good physiological activity, good absorption effect, and prevent the generation of a large number of free amino acids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

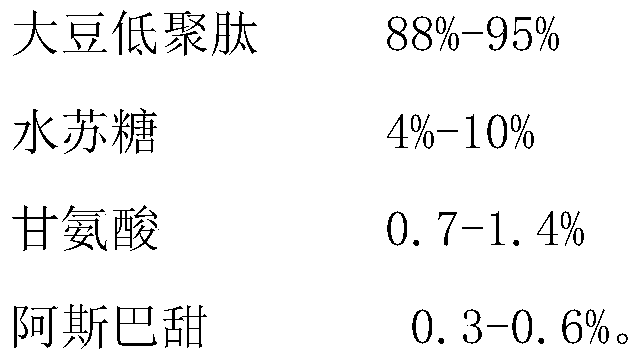

[0028] A soybean oligopeptide powder, comprising the following raw materials in parts by mass:

[0029] Soy oligopeptide 88%-95%

[0030] Stachyose 4%-10%

[0031] Glycine 0.7-1.4%

[0032] Aspartame 0.3-0.6%.

[0033] The preparation method of soybean oligopeptide powder comprises the steps:

[0034] Step 1, dispersion and hydration of soybean protein isolate powder: the soybean protein isolate powder is prepared as protein slurry with deionized water, and the soybean protein isolate slurry is dispersed and hydrated by shearing;

[0035] Step 2, enzymatic hydrolysis while ultrafiltration: adjust the pH value of the protein slurry to 8-9, add a compound protease equivalent to 1-4% of the mass of soybean protein isolate powder, stir and hydrolyze at 50°C-55°C for 3-4h, the whole enzyme The solution process is carried out in a stirred ultrafiltration device, the cut-off flow of the filter membrane in the stirred ultrafiltration device is above 1000Da, and small molecules wit...

Embodiment 2

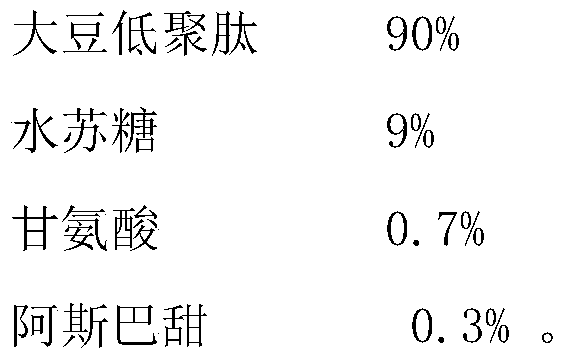

[0041] A soybean oligopeptide powder, comprising the following raw materials in parts by mass:

[0042] Soy Oligopeptides 90%

[0043] Stachyose 9%

[0044] Glycine 0.7%

[0045] Aspartame 0.3%.

[0046] The preparation method of soybean oligopeptide powder comprises the steps:

[0047] Step 1, dispersion and hydration of soybean protein isolate powder: the soybean protein isolate powder is prepared as protein slurry with deionized water, and the soybean protein isolate slurry is dispersed and hydrated by shearing;

[0048] Step 2, enzymatic hydrolysis while ultrafiltration: adjust the pH value of the protein slurry to 8-9, add a compound protease equivalent to 1-4% of the mass of soybean protein isolate powder, stir and hydrolyze at 50°C-55°C for 3-4h, the whole enzyme The solution process is carried out in a stirred ultrafiltration device, the cut-off flow of the filter membrane in the stirred ultrafiltration device is above 1000Da, and small molecules with a molecular w...

Embodiment 3

[0054] A soybean oligopeptide powder, comprising the following raw materials in parts by mass:

[0055] Soy Oligopeptides 92%

[0056] Stachyose 6%

[0057] Glycine 1.2%

[0058] Aspartame 0.6%.

[0059] The preparation method of soybean oligopeptide powder comprises the steps:

[0060] Step 1, dispersion and hydration of soybean protein isolate powder: the soybean protein isolate powder is prepared as protein slurry with deionized water, and the soybean protein isolate slurry is dispersed and hydrated by shearing;

[0061] Step 2, enzymatic hydrolysis while ultrafiltration: adjust the pH value of the protein slurry to 8-9, add a compound protease equivalent to 1-4% of the mass of soybean protein isolate powder, stir and hydrolyze at 50°C-55°C for 3-4h, the whole enzyme The solution process is carried out in a stirred ultrafiltration device, the cut-off flow of the filter membrane in the stirred ultrafiltration device is above 1000Da, and small molecules with a molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com