Stone pretreatment method for stone reverse beating process

A pretreatment and stone technology, applied in the field of stone treatment, can solve the problems of uneven interface agent on the back of stone, interface agent scraping, interface agent efflorescence, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

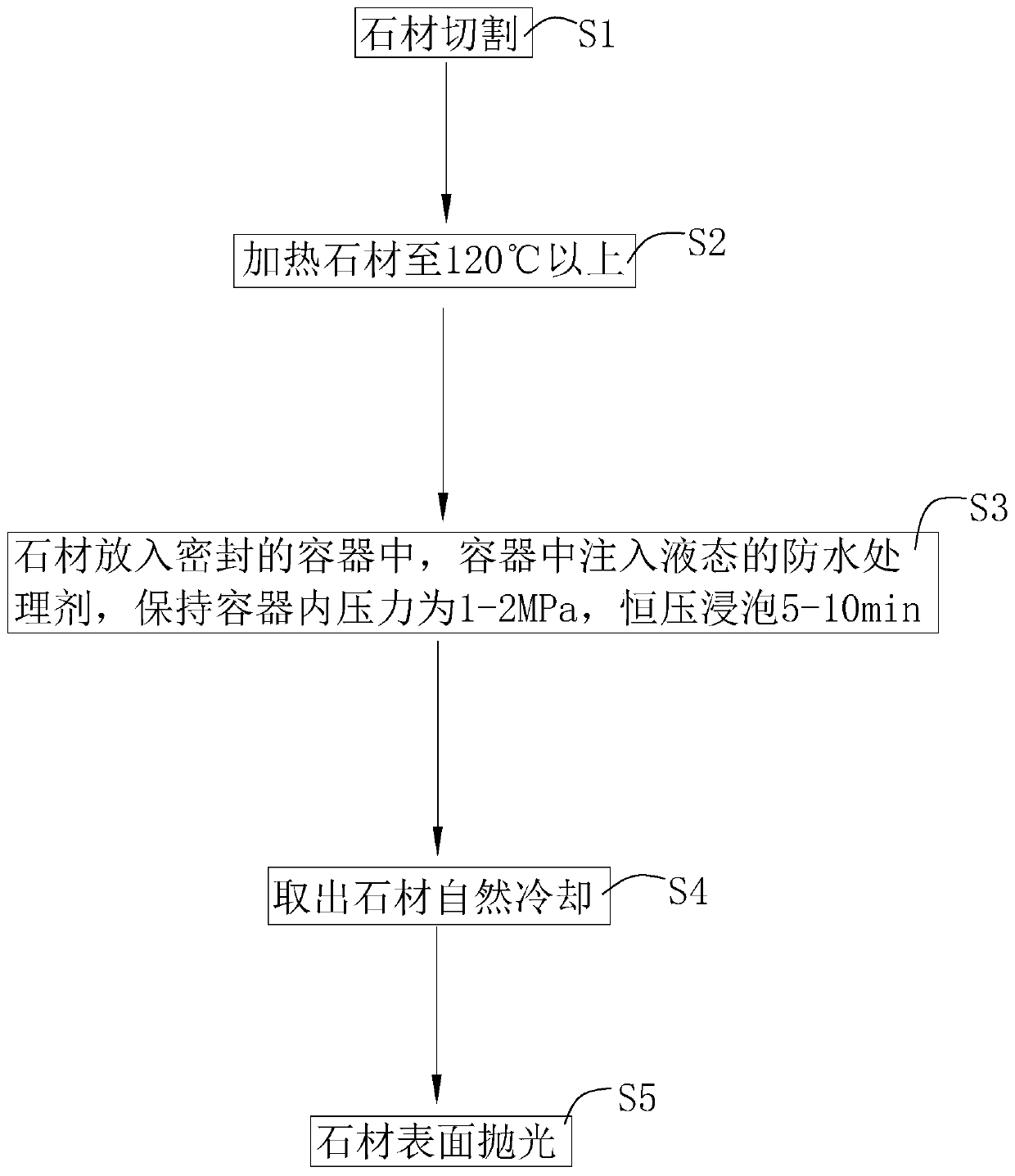

[0067] refer to figure 1 , is a kind of stone material pretreatment method that is used for stone material anti-beating process disclosed by the present invention, comprises the following steps:

[0068] S1. Stone cutting, cut the stone according to the need to form a regular stone.

[0069] S2. Put the stone into the oven and heat it to 180°C, and keep the temperature at 180°C for 30min.

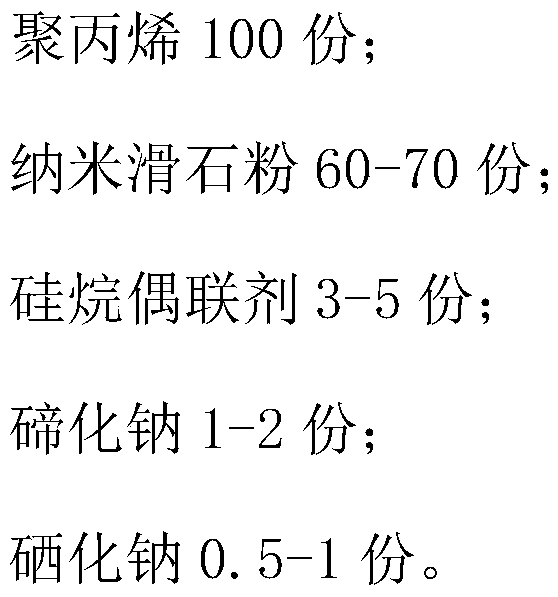

[0070] S3. Take the stone out of the oven, put the box in a sealable box with a heating device, and the box is connected with an air outlet pipe and a liquid injection pipe. There is an air outlet valve connected to the air pipe. After the air outlet valve on the pipe wall, the waterproof treatment agent heated to 180°C is injected into the box through the liquid pump through the liquid injection pipe. The liquid injection pipe is equipped with a pressure gauge and a liquid injection valve. The gauge pressure is 1MPa, close the liquid injection valve, start the wall heating device, contro...

Embodiment 2

[0078] refer to figure 1 , is a kind of stone material pretreatment method that is used for stone material anti-beating process disclosed by the present invention, comprises the following steps:

[0079] S1. Stone cutting, cut the stone according to the need to form a regular stone.

[0080] S2. Put the stone into an oven and heat it to 190°C, and keep the temperature at 190°C for 30 minutes.

[0081] S3. Take the stone out of the oven, put the box in a sealable box with a heating device, and the box is connected with an air outlet pipe and a liquid injection pipe. There is an air outlet valve connected to the air pipe. After the air outlet valve on the pipe wall, the waterproof treatment agent heated to 185°C is injected into the box through the liquid pump through the liquid injection pipe. The liquid injection pipe is equipped with a pressure gauge and a liquid injection valve. The gauge pressure is 1.5MPa, close the liquid injection valve, start the wall heating device, ...

Embodiment 3

[0089] refer to figure 1 , is a kind of stone material pretreatment method that is used for stone material anti-beating process disclosed by the present invention, comprises the following steps:

[0090] S1. Stone cutting, cut the stone according to the need to form a regular stone.

[0091] S2. Put the stone into an oven and heat it to 200°C, and keep the temperature at 200°C for 30 minutes.

[0092] S3. Take the stone out of the oven, put the box in a sealable box with a heating device, and the box is connected with an air outlet pipe and a liquid injection pipe. There is an air outlet valve connected to the air pipe. After the air outlet valve on the pipe wall, the waterproof treatment agent heated to 190°C is injected into the box through the liquid pump through the liquid injection pipe. The liquid injection pipe is equipped with a pressure gauge and a liquid injection valve. The gauge pressure is 2MPa, close the liquid injection valve, start the wall heating device, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com