A negative pressure dehydration and harmless treatment process for dead animals

A technology for harmless treatment of dead animals, applied in waste treatment, chemical instruments and methods, solid waste removal, etc., can solve the problems of environment and equipment impact, high energy consumption, etc., and achieve low cost, high dehydration efficiency, and energy efficiency. consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

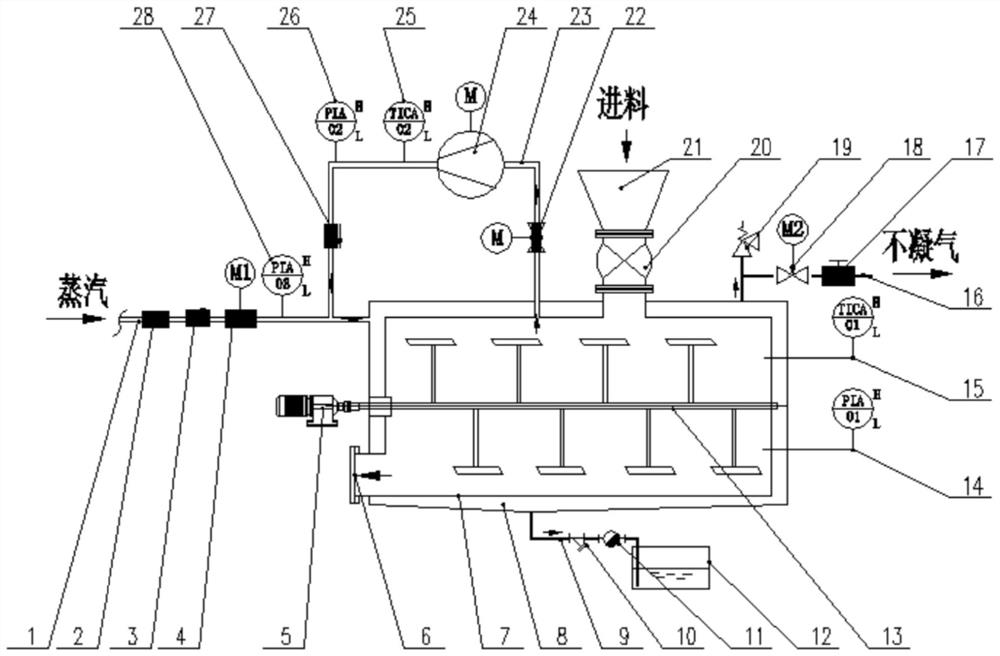

[0037] Refer to attached figure 1 , In the harmless treatment process of negative pressure evaporation system for dehydration of sick and dead animals, the process equipment includes: chemical dehydration chamber, steam pipeline system, secondary steam compression recovery pipeline system, condensate collection system, non-condensable gas exhaust systems, control systems, etc.;

[0038] Further, the chemical dehydration chamber includes a stirring motor (5), a stirring shaft (13), a tank inner cavity (7), a tank heating chamber (8), a feed inlet (21), a feed ball valve (20) , outlet (6) and other components;

[0039] The steam pipeline system includes steam gas supply pipeline (1), pressure reducing valve (2), one-way valve 1 (3), electric regulating valve (4) and other components;

[0040] The secondary vapor compression reuse pipeline system includes components such as a vapor compression pipeline (23), an electric ball valve (22), a vapor compressor (24), and a one-way va...

Embodiment 2

[0048] A negative pressure dehydration and harmless treatment device for dead animals, comprising: a tank body cavity 7, a tank body heating cavity 8; the top of the tank body cavity 7 is connected to the inlet of a vapor compression pipeline 23; the tank body heating cavity One side of 8 is connected with the steam gas supply pipeline 1; the bottom of the tank heating chamber 8 is connected with the condensate pipe 9, and the top is connected with the non-condensable gas exhaust pipe 16; the steam compression pipeline 23 is connected with the electric ball valve 22, The steam compressor 24 and the one-way valve (2) 27 are connected in sequence, and the outlet is connected to the end of the steam supply pipeline 1 .

[0049] The invention adopts negative pressure low-temperature evaporation and vapor compression recycling technology to realize low-temperature dehydration to avoid evaporation of low-boiling oil with water, and at the same time, the secondary vapor generated by d...

Embodiment 3

[0051] A negative pressure dehydration and harmless treatment device for dead animals, comprising: a tank body cavity 7, a tank body heating cavity 8; the top of the tank body cavity 7 is connected to the inlet of a vapor compression pipeline 23; the tank body heating cavity One side of 8 is connected with the steam gas supply pipeline 1; the bottom of the tank heating chamber 8 is connected with the condensate pipe 9, and the top is connected with the non-condensable gas exhaust pipe 16; the steam compression pipeline 23 is connected with the electric ball valve 22, The steam compressor 24 and the one-way valve (2) 27 are connected in sequence, and the outlet is connected to the end of the steam supply pipeline 1 .

[0052] The upper part of the tank inner cavity 7 is provided with a feed inlet 21, and the lower part is provided with a discharge port 6, and a stirring device 13 is provided in the tank body; a tank heating chamber 8 is provided at the bottom of the tank body; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com