A kind of hybrid material of polybipyridine zinc complex modified mil-101 and preparation method and application of catalytic organophosphorus degradation

A technology of zinc polypyridine and hybrid material is applied in the application of catalytic organophosphorus degradation, and the field of hybrid material and preparation of MIL-101 modified by zinc polypyridine complex can solve the problem that the active species LM-OH cannot exist stably , the problem of low catalytic hydrolysis rate and efficiency, etc., to achieve the effect of good catalytic cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of each buffer solution involved in the present invention is as follows:

[0044] 50mM pH 7.0 N-ethylmorpholine buffer: Weigh 288 mg of N-ethylmorpholine into a beaker containing 45 ml of distilled water, adjust with 1mol / L hydrochloric acid or 1mol / L sodium hydroxide The pH of the solution was close to 7.0, transferred to a 50-ml volumetric flask, and a small amount of water from rinsing the flask was also added to the volumetric flask to make up to 50 ml. Then use a small amount of 1 mol / L hydrochloric acid or 1 mol / L sodium hydroxide to adjust the pH of the solution to 7.0.

[0045] 50mM pH 8.0 N-Ethylmorpholine buffer: Weigh 288 mg of N-Ethylmorpholine into a beaker containing 45 mL of distilled water, adjust with 1mol / L hydrochloric acid or 1mol / L sodium hydroxide The pH of the solution was close to 8.0, transferred to a 50-mL volumetric flask, and a small amount of water from rinsing the flask was also added to the volumetric flask to make ...

Embodiment 1

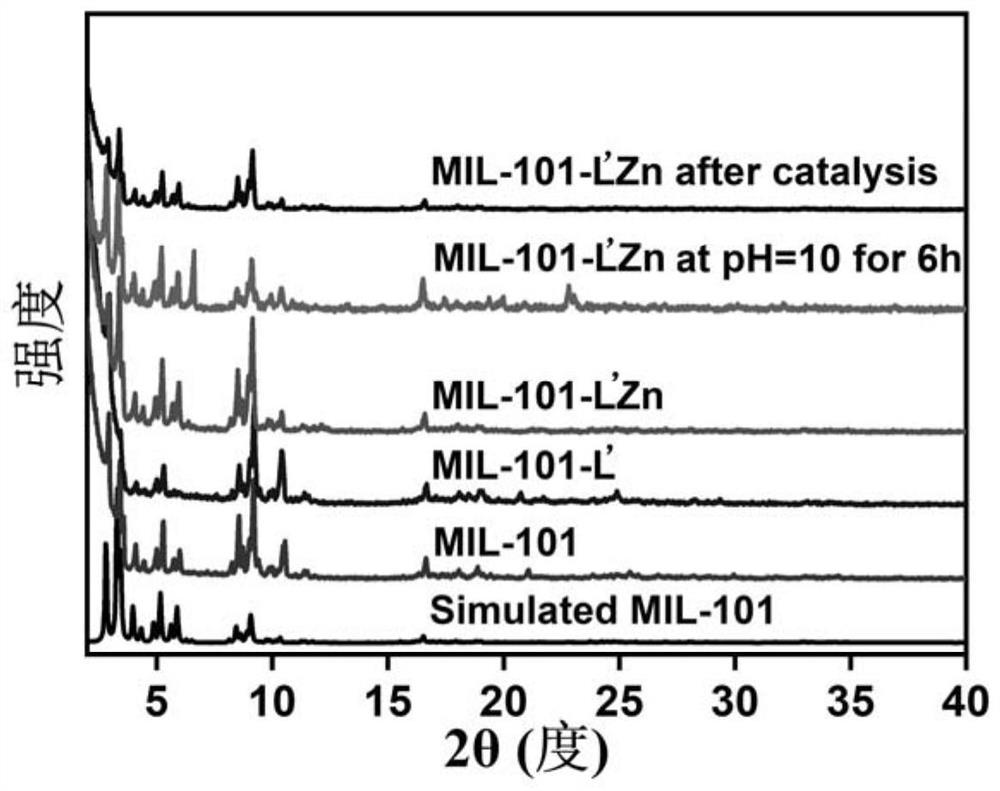

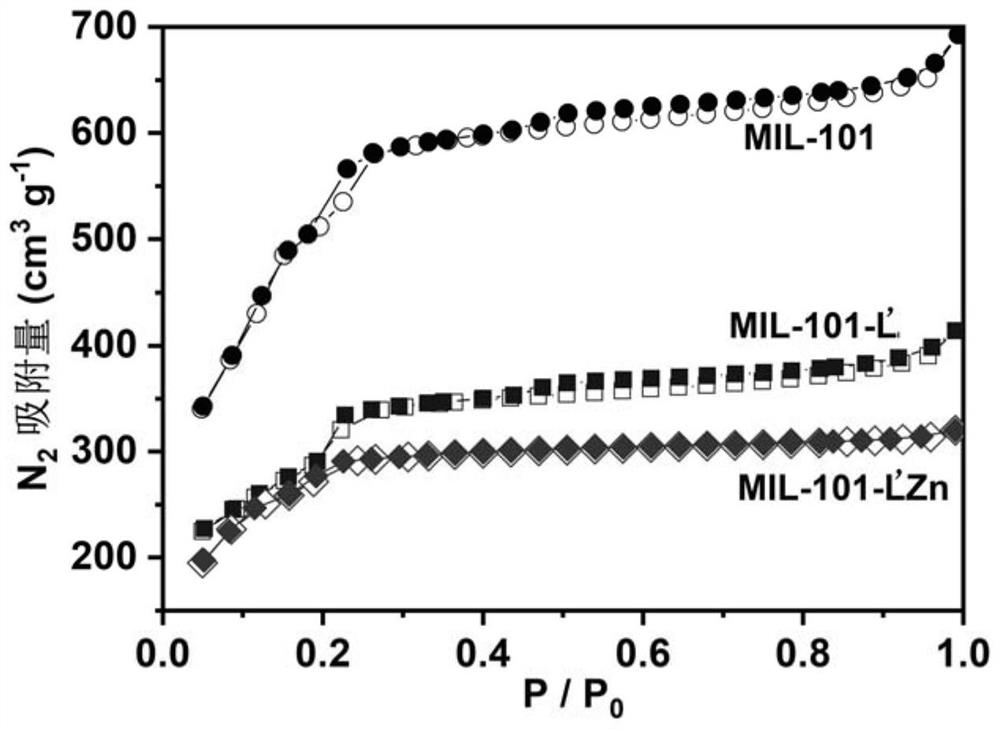

[0049] A preparation method of a hybrid material of MIL-101 modified by a polybipyridine zinc complex, comprising the following steps:

[0050] (1) Preparation of MIL-101 activated by decoordinated water: Weigh 4.33 g (10.82 mmol) of chromium nitrate nonahydrate and 1.80 g (10.83 mmol) of terephthalic acid and ultrasonically disperse them in 52 mL of deionized water. The ultrasonic dispersion is uniform. , and 0.3 mL (1.5 mmol) of a 42% HF aqueous solution was added dropwise. The above prepared solution was added to a polytetrafluoroethylene-lined autoclave, and heated in a 473K oven for 8 hours. In order to remove impurities in the pores of MIL-101, MIL-101 was refluxed with 450 ml of deionized water for 24 hours, filtered while hot, and then MIL-101 was refluxed with 450 ml of ethanol twice for 24 hours each time, using hot ethanol Washed and filtered, and the obtained crystals were re-used containing NH 4 The aqueous solution of F was refluxed for 24 hours, filtered while...

Embodiment 2

[0056] A preparation method of a hybrid material of MIL-101 modified by a polybipyridine zinc complex, comprising the following steps:

[0057] (1) with step (1) in embodiment 1;

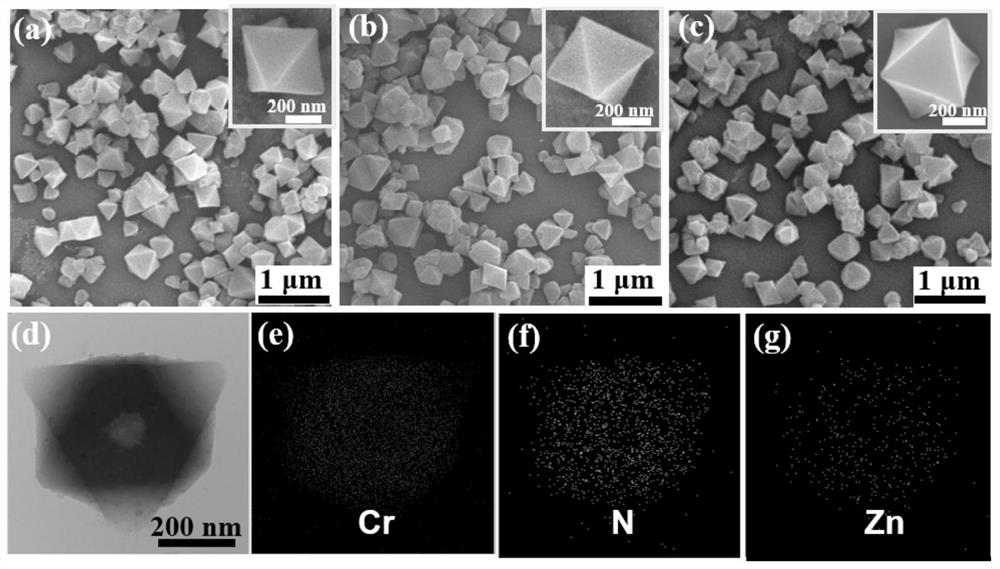

[0058] (2) Preparation of MIL-101-L': Dissolve 37.2 mg of ligand L, namely 4'-(4-pyridyl)-2,2':6',2"-terpyridine in 13 ml of anhydrous toluene 55.8mg of MIL-101 activated by the above steps was added, ultrasonically dispersed for 5 minutes, and then refluxed at 378K for 16 hours, centrifuged, washed three times with toluene and ethanol, and placed in a vacuum drying box at 353K after centrifugation. 12 hours.

[0059] (3) Preparation of MIL-101-L'Zn: 32.8 mg of Zn (CH 3 COOH) 2· 2H 2 O was dissolved in a mixed solvent of 15mL methanol and water (v / v=1:1.1), under vigorous stirring, 65.5mg MIL-101-L' was added, heated under reflux at 343K for 5 hours, centrifuged, and washed three times with methanol , after centrifugation, it was placed in a vacuum drying oven at 353K and dried for 12 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com