Method for continuously synthesizing diethyl phosphite in microchannel reactor

A technology of diethyl phosphite and microchannel reactor, which is applied in chemical instruments and methods, chemical/physical/physicochemical reactors, climate sustainability, etc., can solve the problem of diethyl phosphite yield decline, difficult Guarantee product quality, difficult to control reaction temperature and other issues, to achieve the effect of improving production efficiency, good temperature and safety controllability, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

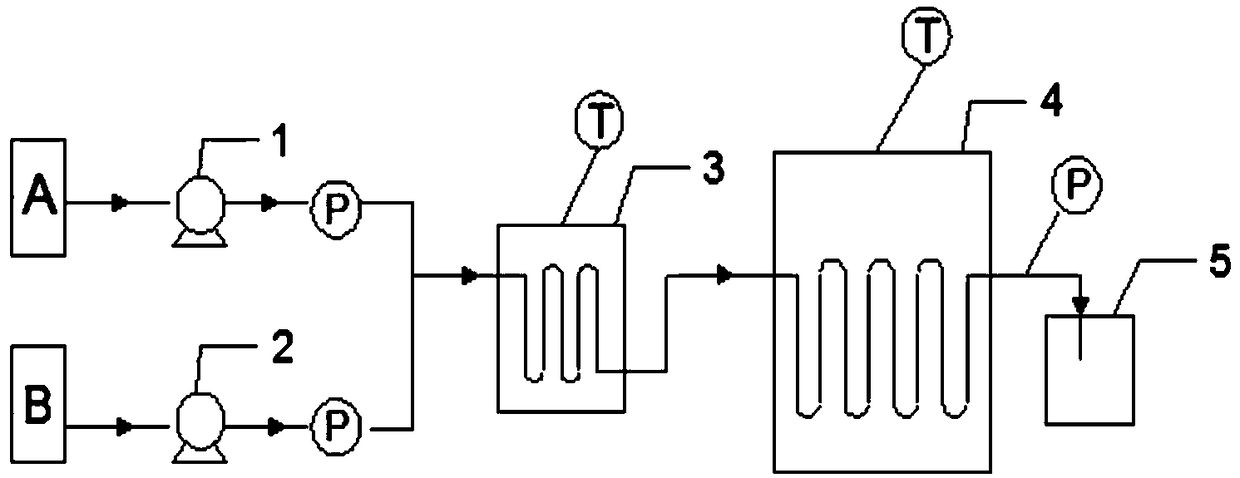

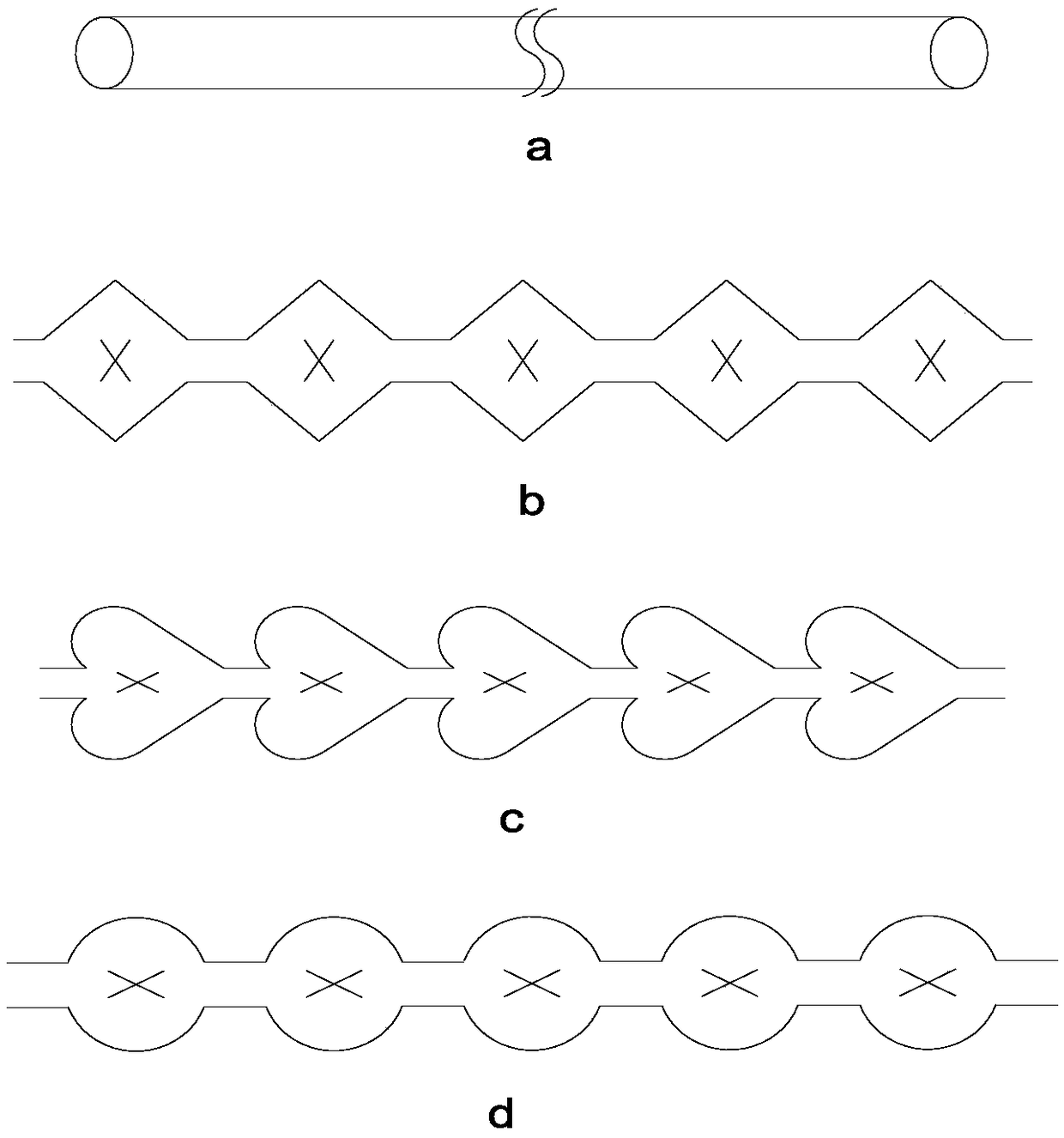

[0030] (1) Reference figure 2 Determine the connection method of the tubular reactor. The pipeline type is a straight structure and a diamond structure. The volume and flow rate of the pipeline determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0031] Phosphorus trichloride and chloroform are mixed uniformly in a volume ratio of 1:2, which is regarded as raw material A; anhydrous ethanol solution is regarded as raw material B, and the two materials are passed at a flow rate of 48ml / min and 19ml / min respectively The metering pump is injected into the reactor. At this time, n (anhydrous ethanol): n (phosphorus trichloride) = 1:3.5, adopt figure 2 In the microchannel reactor, the temperature is controlled at 30°C, the residence time is 60s, the reaction liquid is quantitatively collected, washed, then distilled under reduced pressure, and finally weighed and calculated to obtain a yield of 99.2% of the product diethyl phosphite. The selectivity...

Embodiment 2

[0033] (1) Reference figure 2 Determine the connection method of the tubular reactor. The pipeline type is a straight-through structure and a heart-shaped structure. The volume and flow rate of the pipeline determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0034] Phosphorus trichloride and chloroform are mixed uniformly at a volume ratio of 1:4, which is regarded as raw material A; anhydrous ethanol solution is regarded as raw material B, and the two materials are passed at a flow rate of 50ml / min and 22ml / min respectively The metering pump is injected into the reactor. At this time, n (anhydrous ethanol): n (phosphorus trichloride) = 1:4, adopt figure 2 In the microchannel reactor, the temperature is controlled at 55°C, the residence time is 300s, the reaction solution is quantitatively collected, washed with water, then distilled under reduced pressure, and finally weighed and calculated to obtain a yield of 99.4% of the product diethyl ph...

Embodiment 3

[0036] (1) Reference figure 2 Determine the connection method of the tubular reactor. The pipeline type is a straight structure and a circular structure. The volume and flow rate of the pipeline determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0037] Phosphorus trichloride and chloroform are mixed uniformly at a volume ratio of 1:5, which is regarded as raw material A; anhydrous ethanol solution is regarded as raw material B, and the two materials are passed at a flow rate of 58ml / min and 25ml / min respectively The metering pump is injected into the reactor. At this time, n (anhydrous ethanol): n (phosphorus trichloride) = 1:4, adopt figure 2 In the microchannel reactor, the temperature was controlled at 55°C, the residence time was 60s, the reaction liquid was quantitatively collected, washed with water, then distilled under reduced pressure, and finally weighed and calculated to obtain a yield of 99.1% of the product diethyl phosphite. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com