Device for removing methyl mercury in low-temperature seawater and manufacturing method thereof

A technology for methylmercury and seawater, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems affecting environmental quality and ecological safety, complicated operation, temperature influence, etc., and achieve faster adsorption speed and structure Uniform, ensure the effect of adsorption removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Simultaneously the present invention also provides a kind of method for preparing above-mentioned device, comprises the following steps:

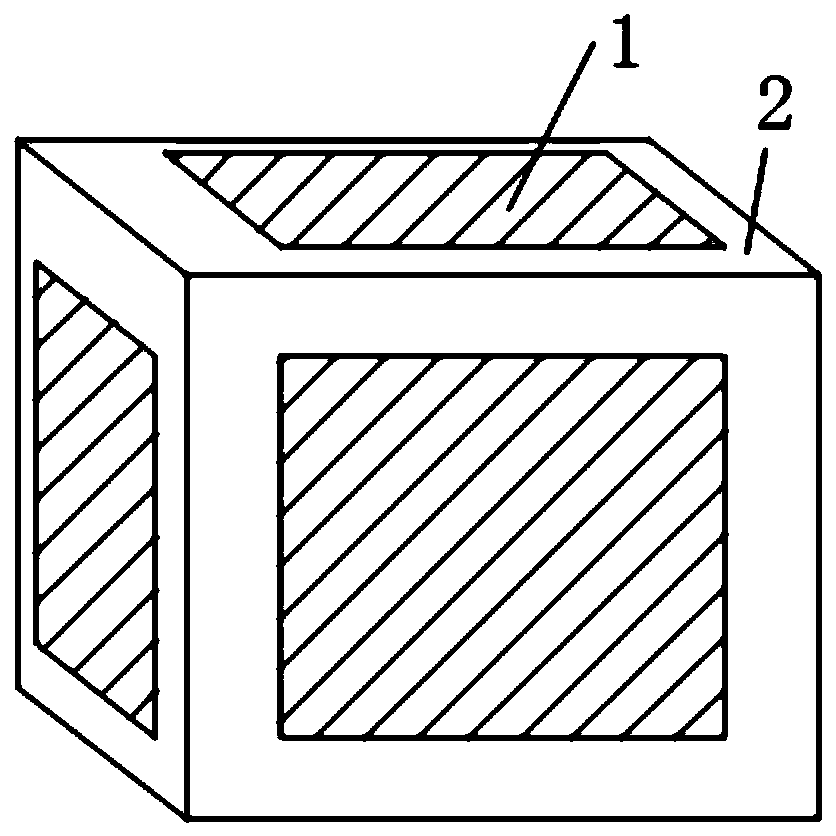

[0033] S1. Dilute 0.48g of particles into ultrapure water preheated to 80°C, mix well, place it in a boiling water constant temperature water bath, cover and stir gently until all the agarose particles are completely dissolved, and the solution It is transparent. Immediately use a pipette to transfer the solution onto a preheated glass slide, and let it stand for 1 hour. After the temperature drops below 36°C, cut the gel into a hexahedron, and dig holes on each side, and finally wash it in ultrapure water. save in .

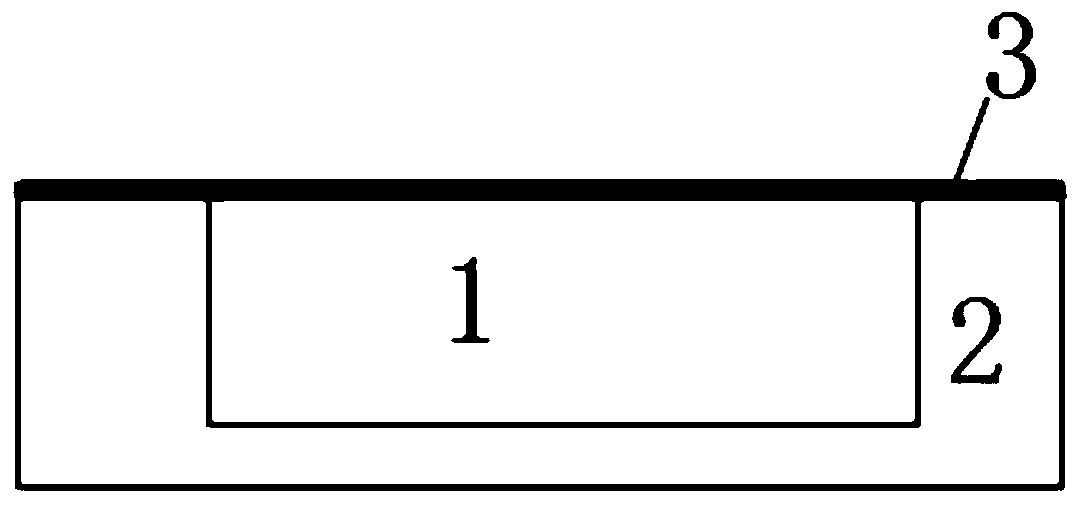

[0034]S2. Take 2.5ml of DGT glue solution and place it in a 10ml plastic centrifuge tube, add 0.38g of mercapto silica gel (1.5g per 10ml), shake to mix well; then add 24μL of ammonium persulfate solution and 7.4μL of TEMED Shake it to make it fully mixed; use a pipette to draw an appropriate amount of the mixed solu...

Embodiment 2

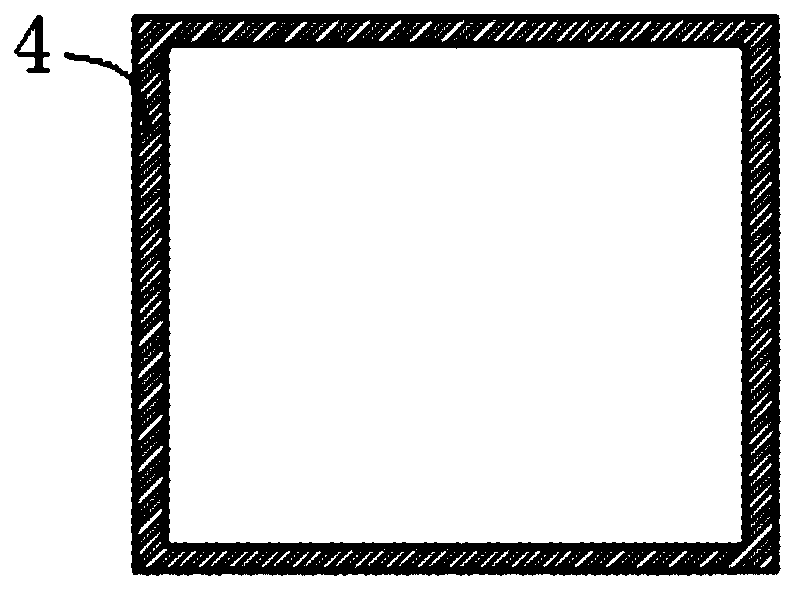

[0037] This embodiment is the same as the method of step S1-S2 in embodiment 1, the difference is that step S3 is different, as follows: S3, take a plurality of plastic plates and hollow out the center, and the 3-mercaptopropyl group cut in step S2 Functionalized silica gel particles are placed in the center groove of each side of the agarose gel, and nitrocellulose membranes are attached to each side of the agarose gel, and then the agarose gels covered with nitrocellulose membranes are placed on each side. Glue is placed in the frame, and finally the remaining plastic sheet is fixed to the frame.

[0038] The present invention increases the contact area between methylmercury and agarose gel by constructing a polyhedron, so that methylmercury can diffuse into 3-mercaptopropyl functionalized silica gel from multiple surfaces, thereby accelerating the functionalization of 3-mercaptopropyl group The adsorption speed of methylmercury on silica gel can promote the rapid purificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com