High-activity catalyst for dimethyl oxalate hydrogenation and preparation method of the high-activity catalyst

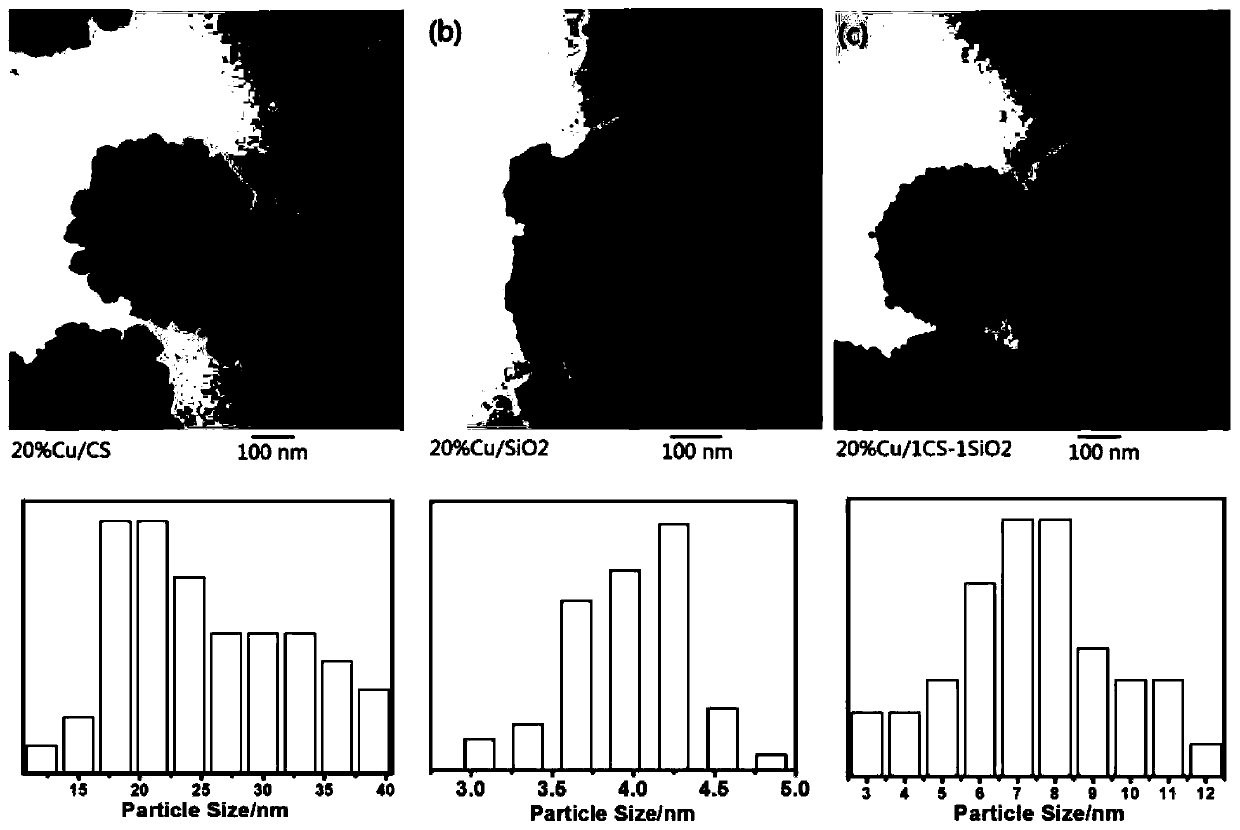

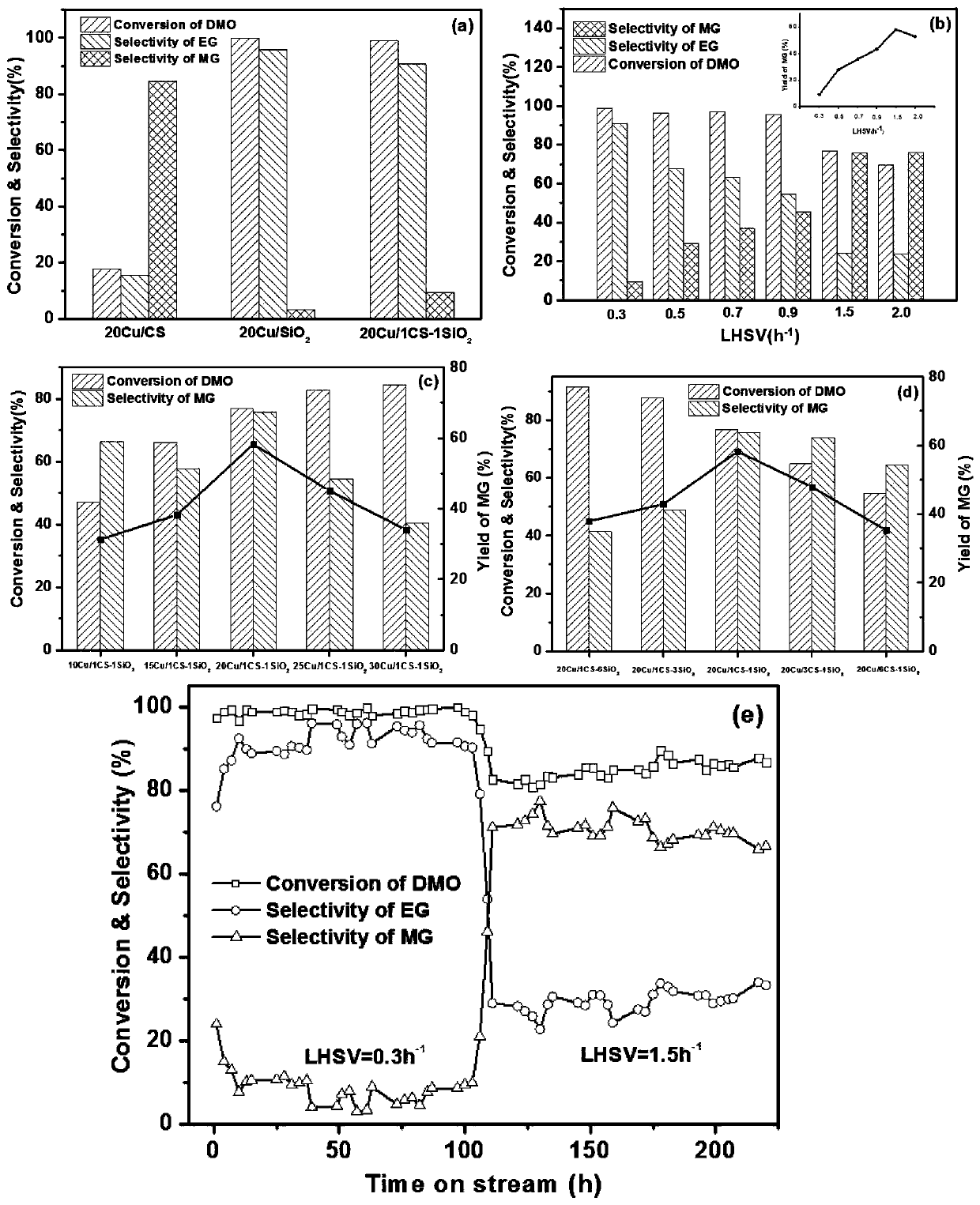

A highly active catalyst, the technology of dimethyl oxalate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of hydroxyl compounds, can solve the problems of improving catalytic performance and poor product selectivity, and achieve excellent catalytic activity. The effect of moderate content and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

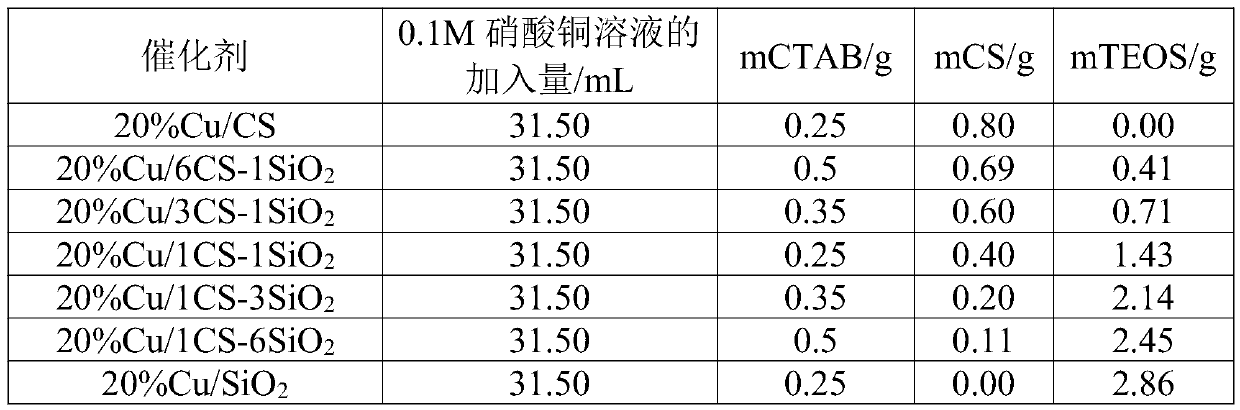

[0024] Embodiment 1: (catalyst 20%Cu / 1CS-1SiO 2 )

[0025] 1) Preparation of carbon microspheres CS

[0026] Prepare 10.27g of sucrose with M=342.3g / mol into a 0.3mol / L solution with deionized water, take 70mL of sucrose aqueous solution and pour it into a reactor with a polytetrafluoroethylene liner, and place the reactor at 180°C In the oven, react for 14 hours, then take the reaction kettle out of the oven and cool it down to room temperature naturally to obtain a brown or black jelly, which is centrifuged and washed three times with deionized water, absolute ethanol, and acetone , and then dried in a drying oven at 80°C for 12 hours to obtain spare carbon microspheres CS;

[0027] 2) Preparation of copper-based catalysts on carbon microspheres-silica composite supports by ammonia distillation

[0028] The carbon microsphere CS prepared in step 1) was dispersed in 0.1M copper nitrate solution, the amount of carbon microsphere CS added was 0.4g, the addition amount of 0.1...

Embodiment 2

[0031] Embodiment 2: (catalyst 20%Cu / 6CS-1SiO 2 )

[0032] 1) Preparation of carbon microspheres CS

[0033] Prepare 10.27g of sucrose with M=342.3g / mol into a 0.3mol / L solution with deionized water, take 100mL of sucrose aqueous solution and pour it into a reaction kettle with a polytetrafluoroethylene liner, and place the reaction kettle at 178°C In the oven, react for 16 hours, then take the reaction kettle out of the oven and cool it down to room temperature naturally to obtain a brown or black jelly, which is centrifuged and washed three times with deionized water, absolute ethanol, and acetone , and then dried in a drying oven at 80°C for 13 hours to obtain spare carbon microspheres CS;

[0034] 2) Preparation of copper-based catalysts on carbon microspheres-silica composite supports by ammonia distillation

[0035] The carbon microspheres CS prepared in step 1) were dispersed in 0.1M copper nitrate solution, the amount of carbon microspheres CS added was 0.69g, the a...

Embodiment 3

[0038] Embodiment 3: (catalyst 20%Cu / 3CS-1SiO 2 )

[0039] 1) Preparation of carbon microspheres CS

[0040] Prepare 10.27g of sucrose with M=342.3g / mol into a 0.3mol / L solution with deionized water, take 80mL of sucrose aqueous solution and pour it into a reactor with a polytetrafluoroethylene liner, and place the reactor at 182°C In the oven, react for 15 hours, then take the reactor out of the oven and cool it down to room temperature naturally to obtain a brown or black jelly, which is centrifuged and washed three times with deionized water, absolute ethanol, and acetone , and then dried in a drying oven at 80°C for 12 hours to obtain spare carbon microspheres CS;

[0041] 2) Preparation of copper-based catalysts on carbon microspheres-silica composite supports by ammonia distillation

[0042] The carbon microspheres CS prepared in step 1) were dispersed in 0.1M copper nitrate solution, the amount of carbon microspheres CS added was 0.6g, the addition amount of 0.1M cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com