Metal-air battery air electrode and preparation method thereof

A metal-air battery and air electrode technology, which is applied to battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve the problems that the porous structure is difficult to control, difficult to obtain, and not clear enough. Achieve the effect of excellent adsorption, stable structure, and prevent excessive heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing an air electrode of a metal-air battery, comprising the following steps:

[0045] S1. Preparation of nitrogen-doped porous carbon:

[0046] The metal-organic framework material and the nitrogen source were prepared into a mixed solution, stirred evenly, and then allowed to stand for adsorption, then centrifuged, washed, and dried; followed by high-temperature carbonization treatment in an inert gas atmosphere, and after carbonization, acid treatment was performed to remove metal particles to obtain Nitrogen-doped porous carbon;

[0047] The high-temperature carbonization treatment includes the following steps: heating at a heating rate of 3-8°C / min, first raising the temperature to 70-90°C and keeping it for 18-30h, then raising the temperature to 130-180°C and keeping it for 5-10h, and finally raising the temperature to 700°C ~1000℃ for 5~10h.

[0048] Preferably, in step S1, the high-temperature carbonization treatment i...

Embodiment 1

[0073] A method for preparing an air electrode of a metal-air battery, comprising the steps of:

[0074] (1) Synthesis of MIL-53(Al) (Levashill framework material whose metal nodes are Al)

[0075] Al(NO 3 ) 3 9H 2 O and terephthalic acid were prepared according to the molar ratio of 1:2.25, added to 30ml of DMF to dissolve completely; then the mixed solution was transferred to a polytetrafluoroethylene reactor, put into an oven, and heated to 393K for constant temperature reaction Cool to room temperature after 72 hours; centrifuge to collect the white solid obtained by the reaction, wash with DMF several times, and finally put it into a 413K oven to dry to obtain MIL-53(Al) powder.

[0076] (2) Preparation of NPC (nitrogen-doped porous carbon)

[0077] Mix 500mg of activated MIL-53(Al) powder, 20ml of sugar alcohol (FA), 5ml of NH 4 OH and 5g of urea were configured into a mixed solution, kept in a stirring state for 12 hours, then stood overnight, and collected solid p...

Embodiment 2

[0085] The preparation method of a kind of metal-air battery air electrode that embodiment 2 provides is compared with embodiment 1, and difference is that step (1) is the synthesis of ZIF-8 (metal node is the zeolite imidazolate framework material of Zn), details as follows:

[0086] Zn(NO 3 ) 2 ·6H 2 O (2.933g, 9.87mmol) was added into 200ml of methanol and stirred to dissolve to form a solution (I), Hmim (2-methylimidazole) (6.489g, 79.04mmol) was added to 200ml of methanol to dissolve to form a solution (II), and then the solution (I) Quickly pour into the solution (II), stir at room temperature for 1 hour to form white crystals. After the obtained product was collected by centrifugation, it was rinsed several times with methanol and dried in a 413K oven.

[0087] Other steps are basically the same as those in Embodiment 1, and will not be repeated here.

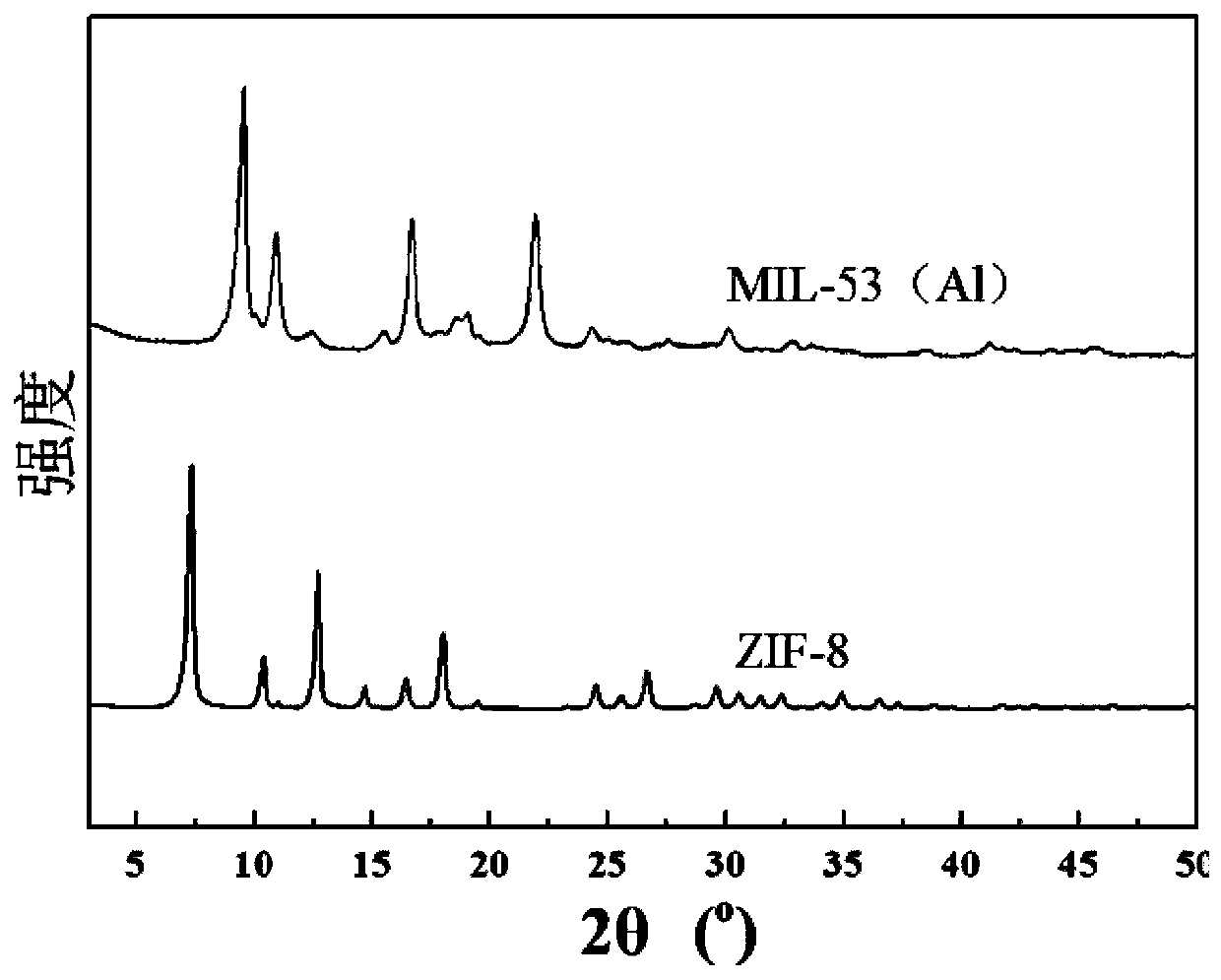

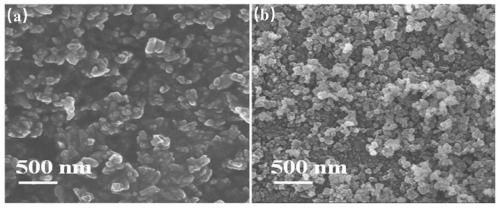

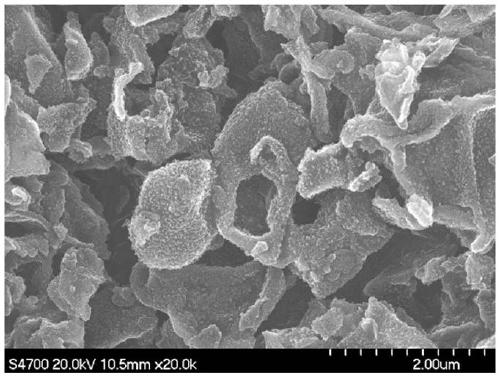

[0088] from Figure 1 to Figure 3 It can be seen that ZIF-8 was successfully prepared in this example, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com