Modified nickel cobalt lithium aluminate positive electrode material and its preparation method and application

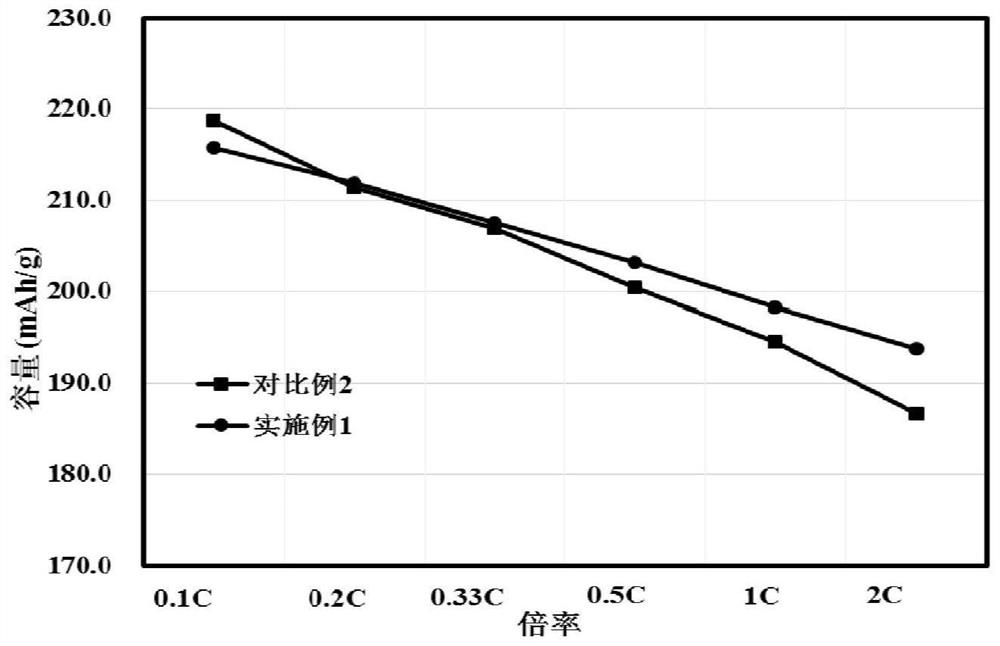

A technology of lithium nickel cobalt aluminate and positive electrode materials, which is applied in battery electrodes, secondary battery repair/maintenance, structural parts, etc., and can solve poor cycle stability and thermal stability, high surface residual Li, low surface residual Li, etc. problems, achieve high cycle rate performance, low surface residual Li, and improve coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The second aspect of the present invention provides a method for preparing a modified nickel-cobalt lithium aluminate positive electrode material, wherein the method includes the following steps:

[0044] (1) Nickel salt, cobalt salt and optional aluminum salt are configured as a mixed salt solution in a molar ratio x:y:z; a compound containing a doping element M, an alkali and a complexing agent are respectively configured as a solution; The mixed salt solution, lye, complexing agent solution, and compound solution containing the doping element M are respectively passed into the reaction kettle to perform the first reaction, and the obtained slurry is separated, washed, dried and screened to obtain the positive electrode material Precursor;

[0045] (2) Mix the positive electrode material precursor obtained in step (1), the lithium source, the compound containing the doping element G and an optional aluminum compound, and in an oxygen atmosphere, carry out the first si...

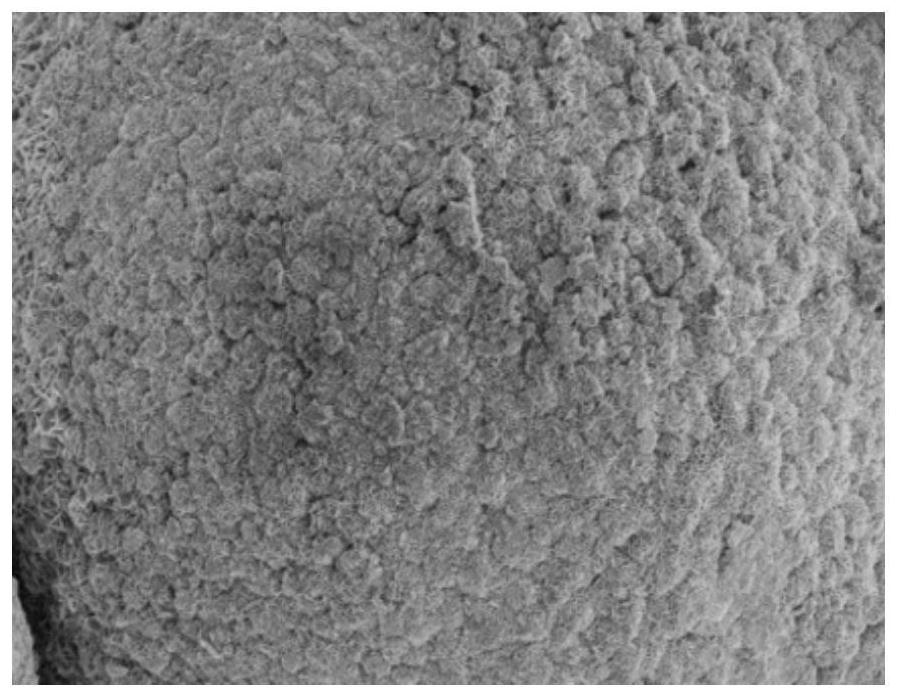

Embodiment 1

[0136] S1, dissolving nickel sulfate and cobalt sulfate according to the ratio of metal molar ratio 0.95:0.05 to obtain a mixed salt solution of 2mol / L, dissolving magnesium nitrate into a magnesium nitrate solution with a concentration of 0.1mol / L, and dissolving calcium nitrate into a concentration of 0.1mol / L calcium nitrate solution, dissolve sodium hydroxide into an alkali solution with a concentration of 8mol / L, and dissolve ammonia water into a complexing agent solution with a concentration of 6mol / L.

[0137]S2. Add the mixed salt solution, magnesium nitrate solution, calcium nitrate solution, alkali solution, and complexing agent solution together into the reactor for reaction. The mixed salt solution inlet flow rate is 400mL / h. The solution inlet flow rate is 16mL / h, the reaction pH is controlled to be 11.5-11.7, the reaction temperature is 60°C, and the concentration of ammonia in the reaction system is controlled to be 8-11g / L. The temperature and stirring speed re...

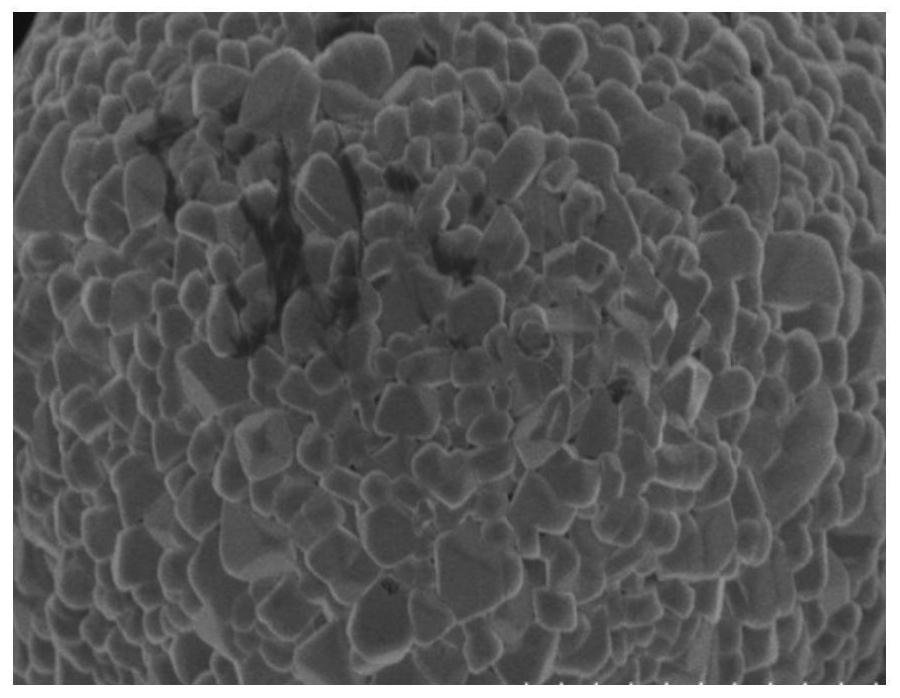

Embodiment 2

[0143] Prepare the positive electrode material according to the same method as in Example 1, except that in the S1 step, nickel sulfate, cobalt sulfate, and aluminum sulfate are dissolved according to the metal molar ratio of 0.92:0.05:0.03 to obtain a 2mol / L mixed salt solution, and finally get spherical Ni 0.9163 co 0.0498 al 0.0299 Mg 0.0020 Ca 0.0020 O oxide precursor.

[0144] In the S3 step lithium hydroxide and Ni 0.9163 co 0.0498 al 0.0299 Mg 0.0020 Ca 0.0020 The O precursor was mixed uniformly in a high mixer according to the molar ratio of 1.05:1, and finally Li 1.05 Ni 0.9163 co 0.0498 al 0.0299 Mg 0.0020 Ca 0.0020 o 2 .

[0145] Other steps are consistent with embodiment 1, finally obtain positive electrode material A2: Li 1.035 Ni 0.9027 co 0.0589 al 0.029 4 m n0.0049 Mg 0.0020 Ca 0.0020 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com