Silicon-tin-oxygen-carbon compound electrode material and preparation method and application thereof

A carbon composite material, carbon composite technology, applied in the direction of active material electrode, nanotechnology for materials and surface science, negative electrode, etc. Density and reversible capacity, good cycle stability, and excellent cycle rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of silicon-tin-oxygen-carbon (Si-Sn-O-C) composite electrode material

[0036] (1) Weigh 2 g of solar cutting waste silicon, add it to 20 mL of acetone solution, ultrasonicate for 60 minutes, centrifuge at 10,000 rpm for 5 minutes, and then vacuum dry at 80°C for 10 hours. After drying, use a ball mill to refine its particles, put 0.5g of waste silicon into a 100 milliliter ball mill tank, the ball-to-material ratio is 40:1, and the rotating speed is 450 rpm, under high-purity (99.9999%) inert gas ( Argon) under the protection of ball milling for 10 hours.

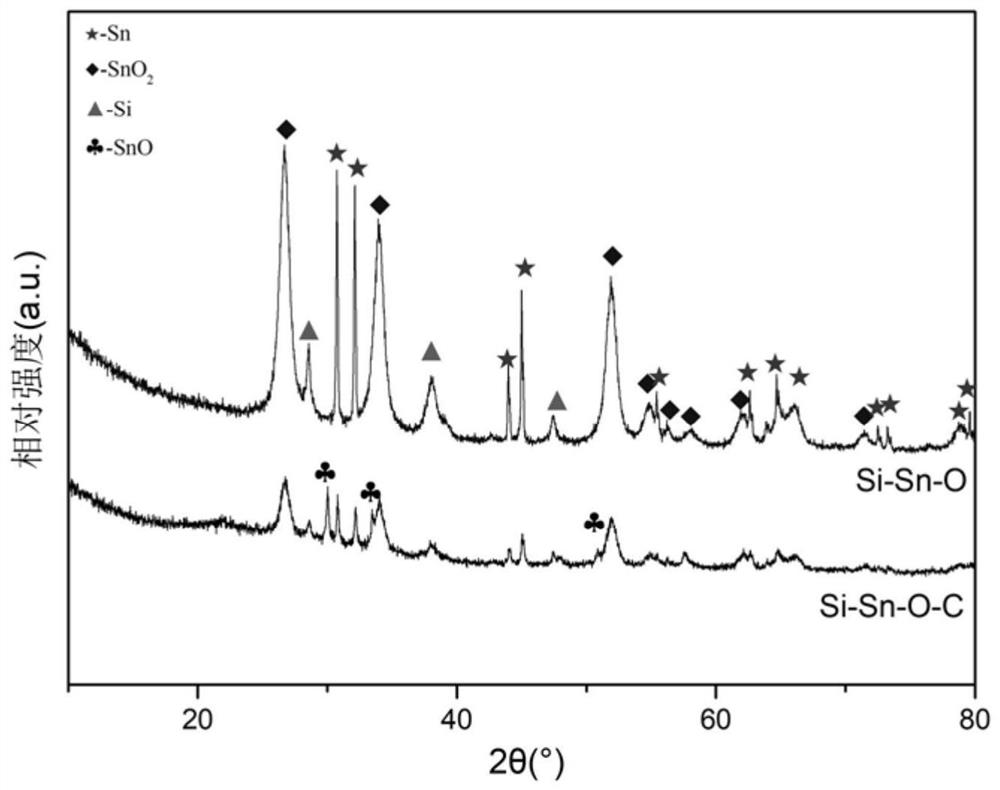

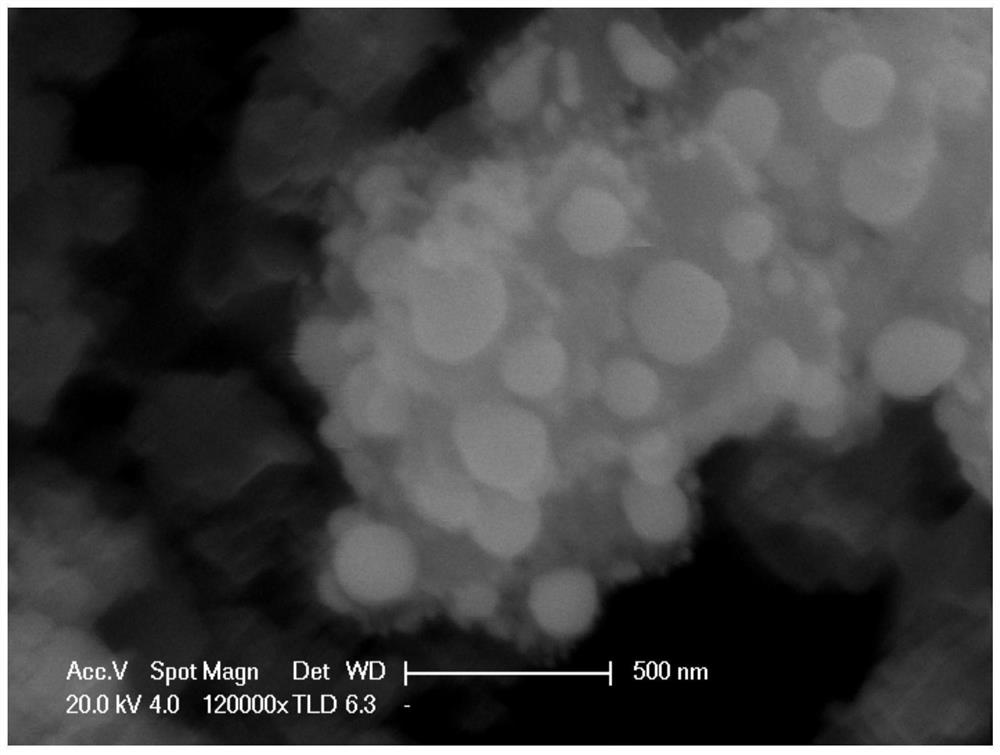

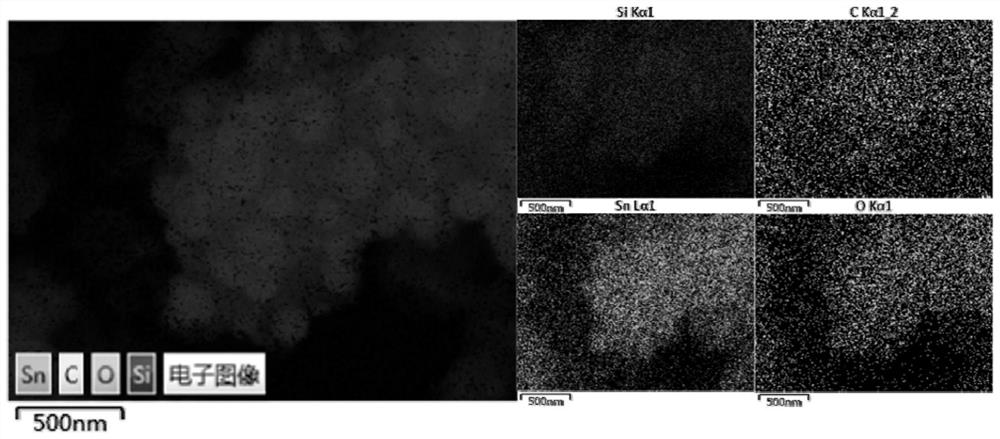

[0037] (2) After ball milling, waste silicon and nano-tin dioxide are mixed in a mortar with a molar ratio of 2:1, and a total of 1 g of waste silicon and nano-tin dioxide mixture is weighed and poured into a crucible, and placed in a tubular calciner Carry out high-temperature heat treatment, raise the temperature to 700°C at a rate of 5°C / min, and keep it warm for 12 hours. During the heating proce...

Embodiment 2

[0060] 1. Preparation of silicon-tin-oxygen-carbon (Si-Sn-O-C) composite electrode material

[0061] (1) Weigh 2 g of solar cutting waste silicon, add it to 20 mL of acetone solution, ultrasonicate for 60 minutes, centrifuge at 10,000 rpm for 5 minutes, and then vacuum dry at 80°C for 10 hours. After drying, use a ball mill to refine its particles, put 0.5g of waste silicon into a 100 milliliter ball mill tank, the ball-to-material ratio is 40:1, and the rotating speed is 450 rpm, under high-purity (99.9999%) inert gas ( Argon) under the protection of ball milling for 10 hours.

[0062] (2) After ball milling, waste silicon and nano-tin dioxide are mixed in a mortar with a molar ratio of 2:1, and a total of 1 g of waste silicon and nano-tin dioxide mixture is weighed and poured into a crucible, and placed in a tubular calciner Carry out high-temperature heat treatment, raise the temperature to 700°C at a rate of 5°C / min, and keep it warm for 12 hours. During the heating proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com