Device and method for preventing winding deformation of spiral copper pipe coil

A copper tube and coil technology, used in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of inconsistent spacing, unstable inductance value of copper tubes, flattening of copper tubes, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

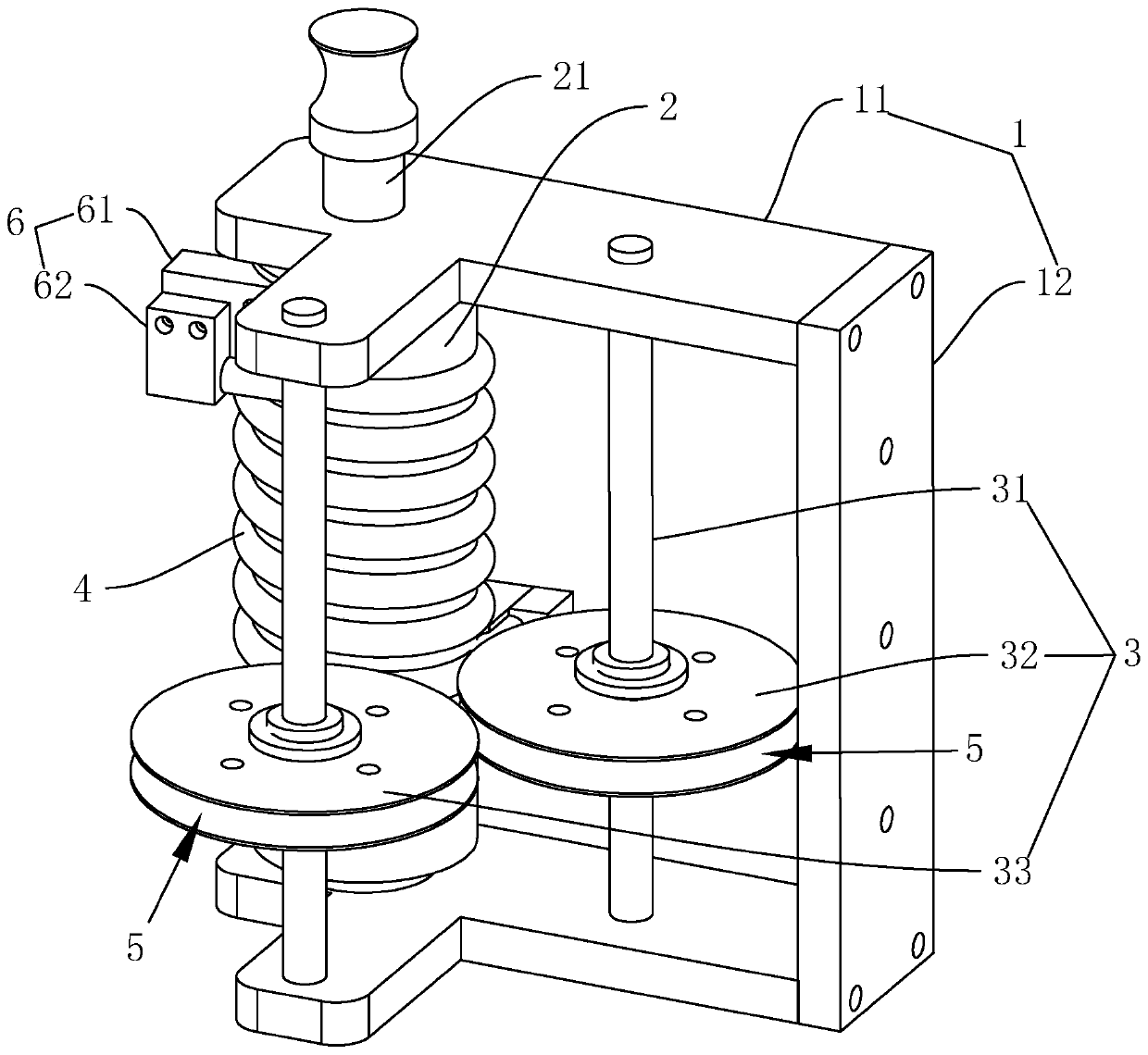

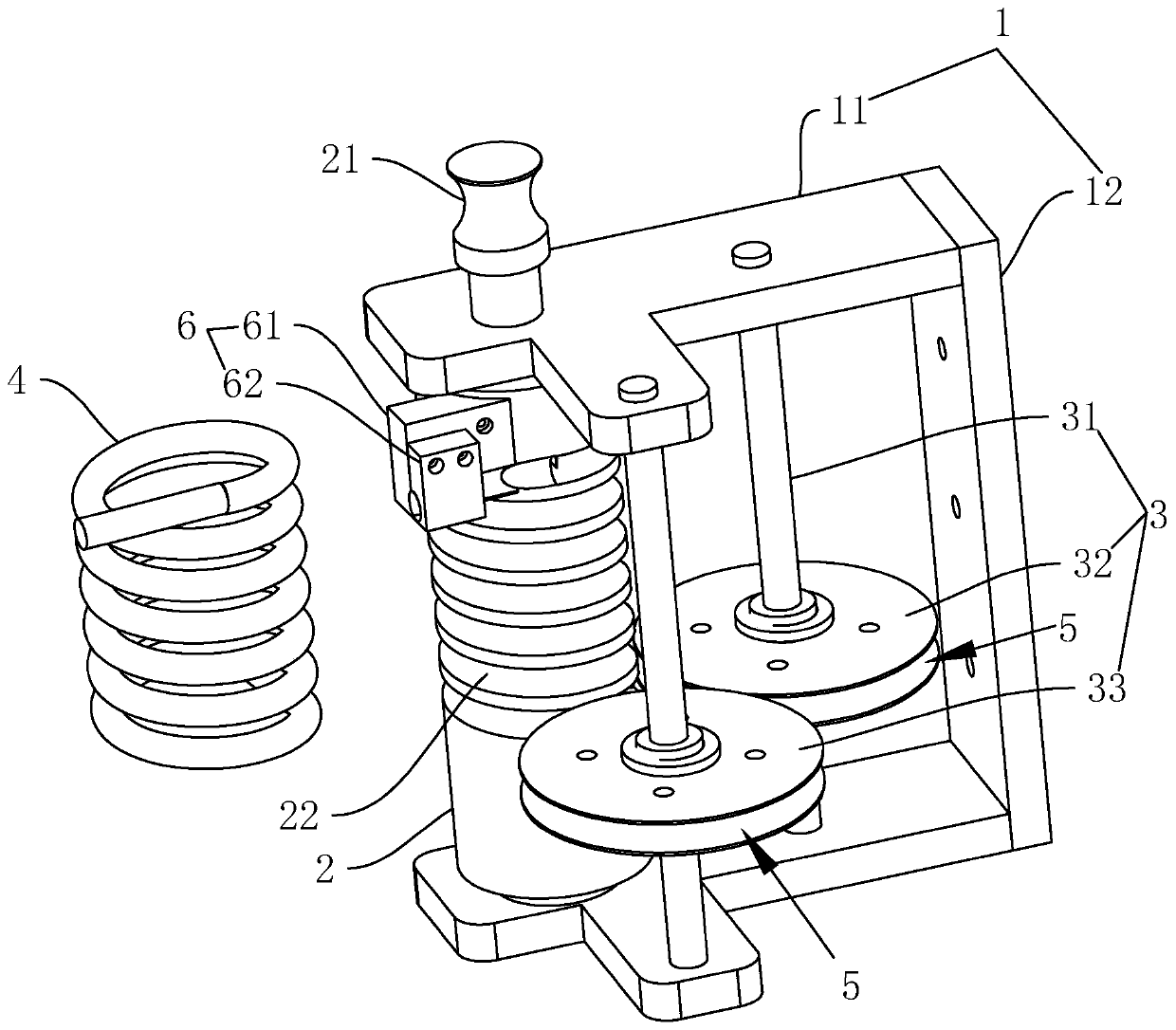

[0046] Embodiment two, refer to figure 1 and figure 2 , a method of use proposed based on the above-mentioned device for preventing the winding deformation of the spiral copper tube coil, which includes:

[0047] S1. First fix the bracket 1 on a workbench, and then fix one end of the cut copper tube to one end of the spiral groove 22 on the winding reel 2 through the starting clamp 6, and the deformation follows the wheel 32 and the setting follower wheel 33 all press the copper tube in the spiral groove 22 by the limiting groove 5 at the starting position of the copper tube bending.

[0048] S2. Rotate the winding reel 2 around the axis of the winding reel 2, so that the copper pipe is wound into the copper pipe coil 4 along the spiral groove 22, and finally the terminal end of the copper pipe is fixed on the termination clamp 6; After the tube coil 4 is formed, keep the copper tube coil 4 in the state on the winding reel 2 for at least two minutes, which can be two minute...

Embodiment 3

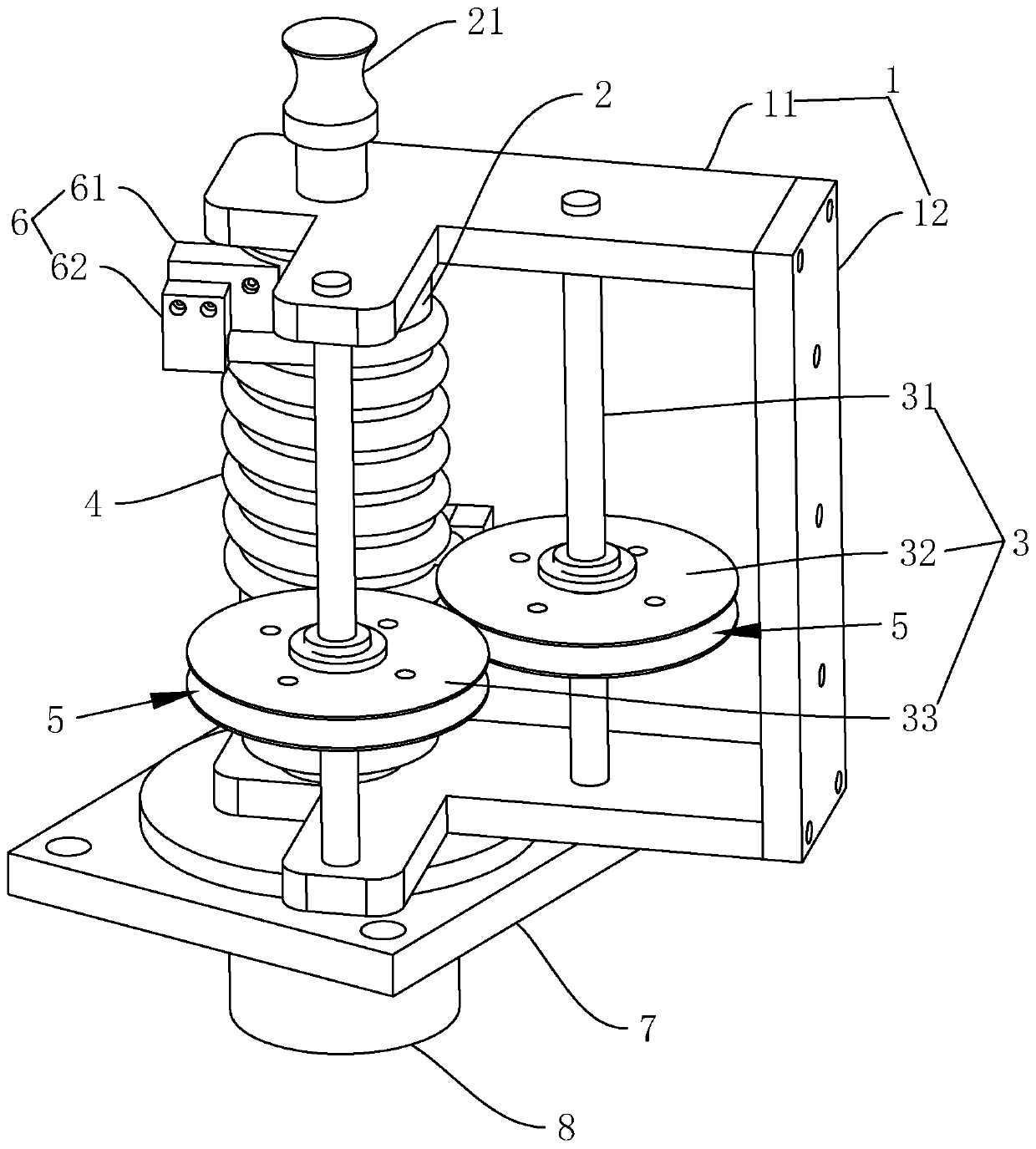

[0050] Embodiment three, refer to image 3 , Compared with Embodiment 1 and Embodiment 2, in Embodiment 3, a base 7 is also fixed by bolts at one end of the bracket 1. The base 7 is in the shape of a cuboid and is made of stainless steel. The round hole through which the connecting shaft 21 on the same side passes; the driver 8 for driving the winding reel 2 to rotate around its own axis is also fixed by screws on the base 7, the driver 8 is a servo motor, and the output shaft of the driver 8 It is connected with the connecting shaft 21 through a coupling, so that the driving member 8 can drive the connecting shaft 21 to rotate around its own axis.

Embodiment 4

[0051] Embodiment four, with reference to Figure 4 Compared with the third embodiment, the fourth embodiment is provided with a socket 211 for inserting other tools to rotate the winding reel 2 on a connecting shaft 21 away from the driving member 8 on the winding reel 2. At this time, the operation A person can insert a tool similar to a round rod into the insertion hole 211, and then turn the tool to achieve the purpose of driving the winding reel 2 to rotate around its own axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com