Middle-mounted wheel core drive electric drive automatic speed change system

An automatic shifting and driving electric technology, applied to vehicle gearboxes, bicycles, motor vehicles, etc., can solve problems such as difficulty in setting up deceleration and shifting mechanisms, inability to use high-speed motors, and unsatisfactory motor efficiency, etc., to reduce distance changes , strong climbing and heavy load capacity, and the effect of extending the deceleration transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

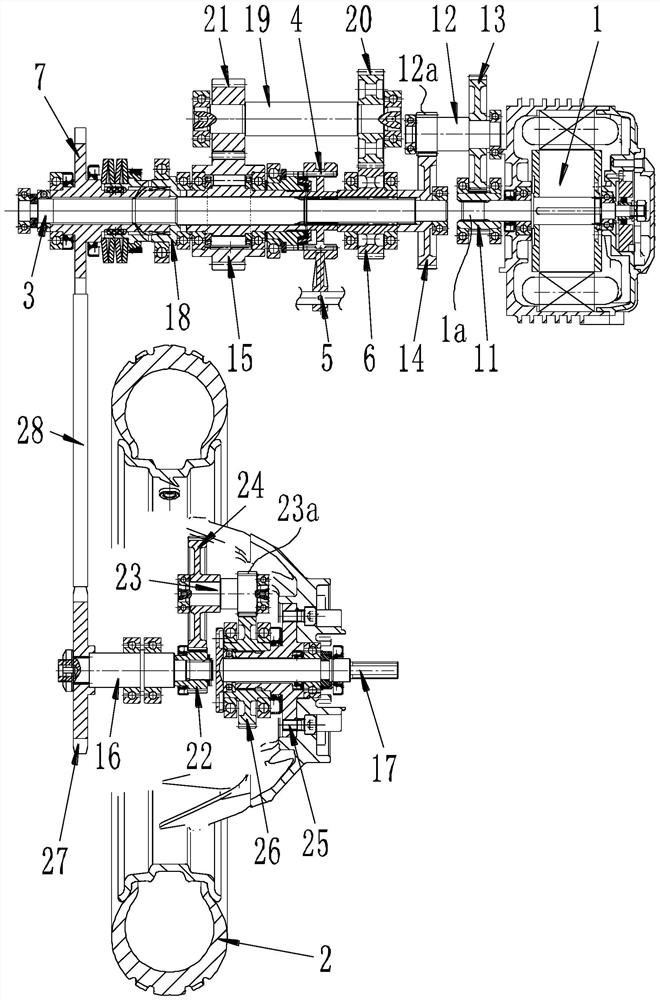

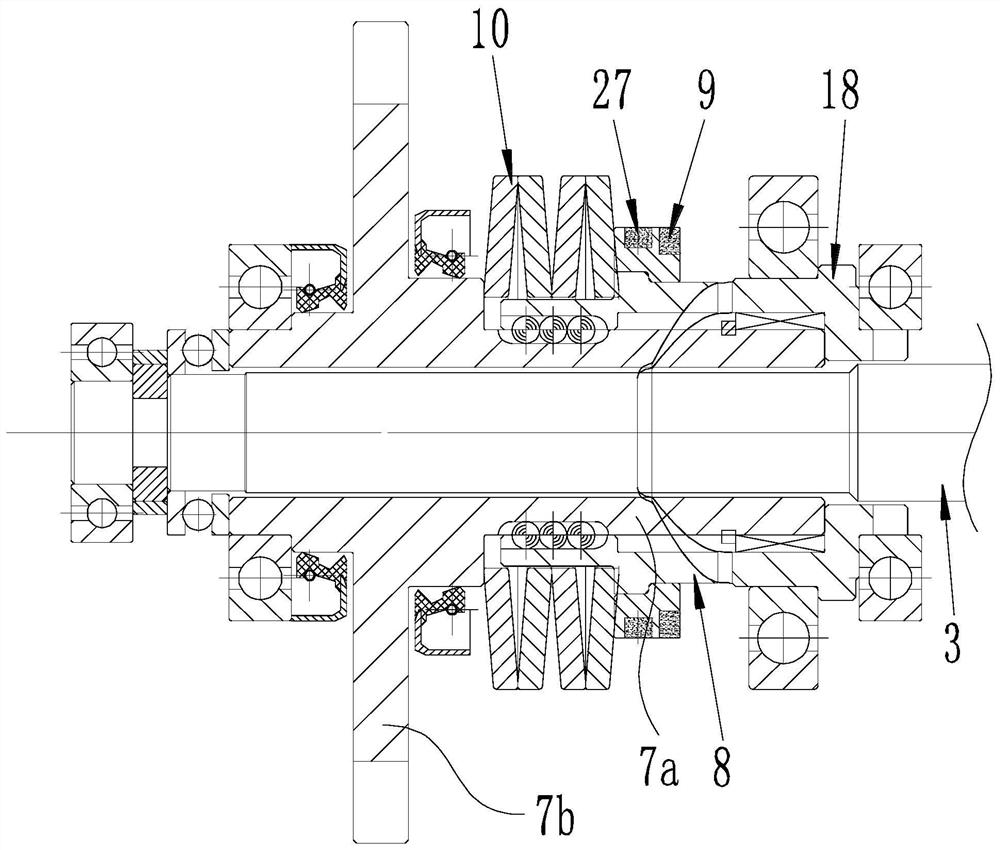

[0030] Such as figure 1 As shown, a center-mounted wheel core-driven electric drive automatic transmission system mainly includes a power input mechanism, a driving wheel 2, a shifting transmission mechanism arranged on the outer intermediate shaft 3, and the outer intermediate shaft through a chain transmission assembly. 3 connected to the in-wheel intermediate shaft 16 and the deceleration output mechanism arranged on the wheel installation shaft 17, the power input mechanism sequentially transmits power to the The deceleration output mechanism drives the drive wheel 2 to rotate by the deceleration output mechanism.

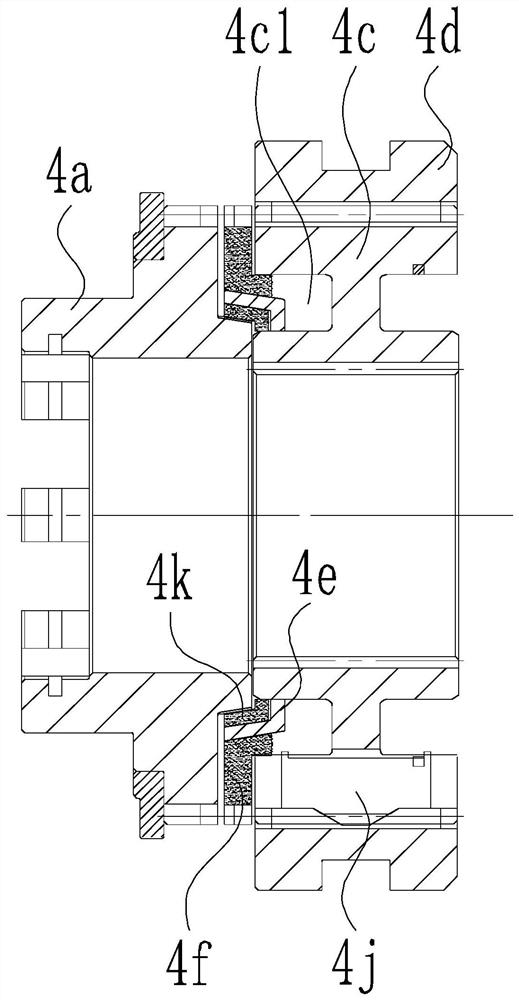

[0031] The shifting transmission mechanism includes a one-sided synchronizer 4, an overrunning clutch 15 and a reduction assembly. The one-side synchronizer 4, the overrunning clutch 15 and the first-stage deceleration driving gear 6 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com