A two-degree-of-freedom parallel lifting mechanism for a three-dimensional garage

A technology of a three-dimensional garage and a lifting mechanism, which is applied in the direction of buildings, building types, and buildings where cars are parked, and can solve problems such as shortening the distance of the scissor support points, reducing the folding ratio of the mechanism, and reducing the stability of the mechanism. Achieve the effect of large unfolding height, large folding-expanding ratio, and increasing the carrying capacity of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

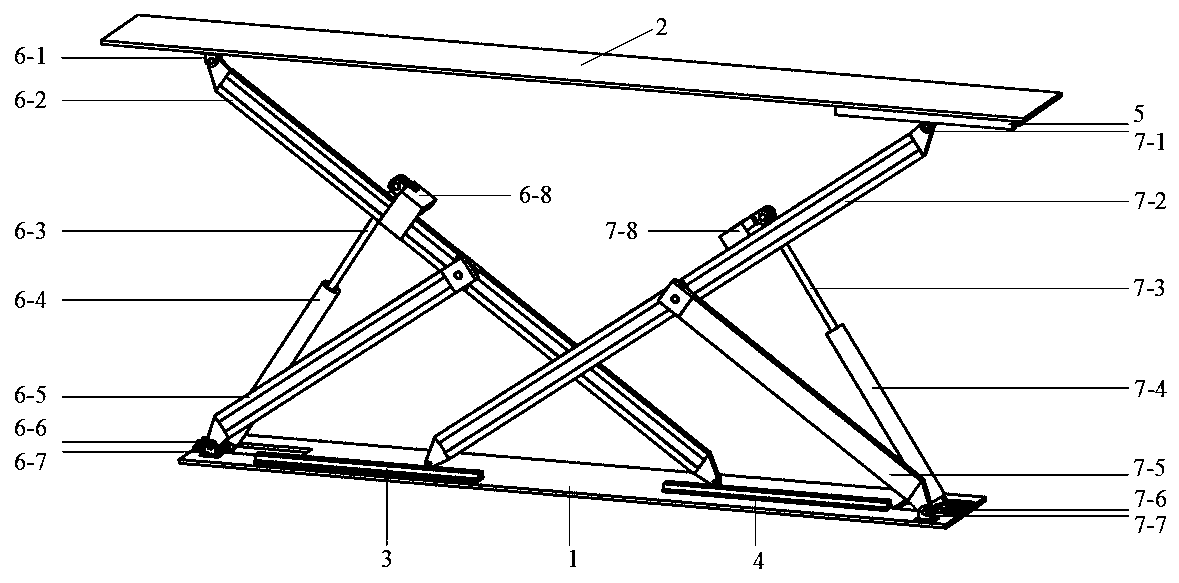

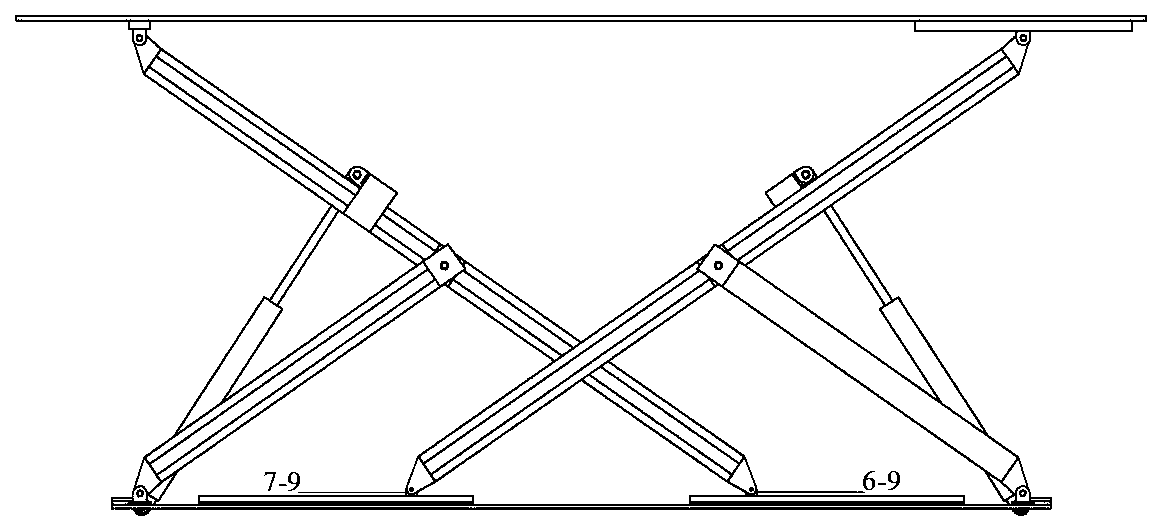

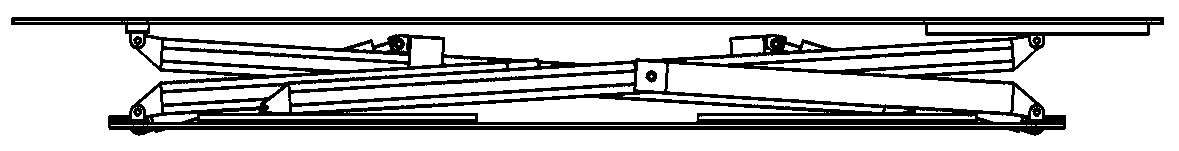

[0015] Such as figure 1 and 2 As shown, the specific embodiment adopts the following technical solutions: it includes a fixed platform 1, a moving platform 2, a first slideway 3, a second slideway 4, a third slideway 5, a left side motion branch chain and a right side motion branch chain. chain. Among them, the left motion branch chain consists of the left moving platform connecting seat 6-1, the left long lifting arm 6-2, the left hydraulic cylinder rod 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com