Noodle belt distributing and stacking machine

A technology of splitting layer and stacking machine, which is applied in the direction of dough processing, dough forming and cutting equipment, baking, etc. It can solve the problems of limited product types, unsuitable for roll forming, and inconvenient production line layout, so as to achieve good product appearance, Multiple types of processing and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

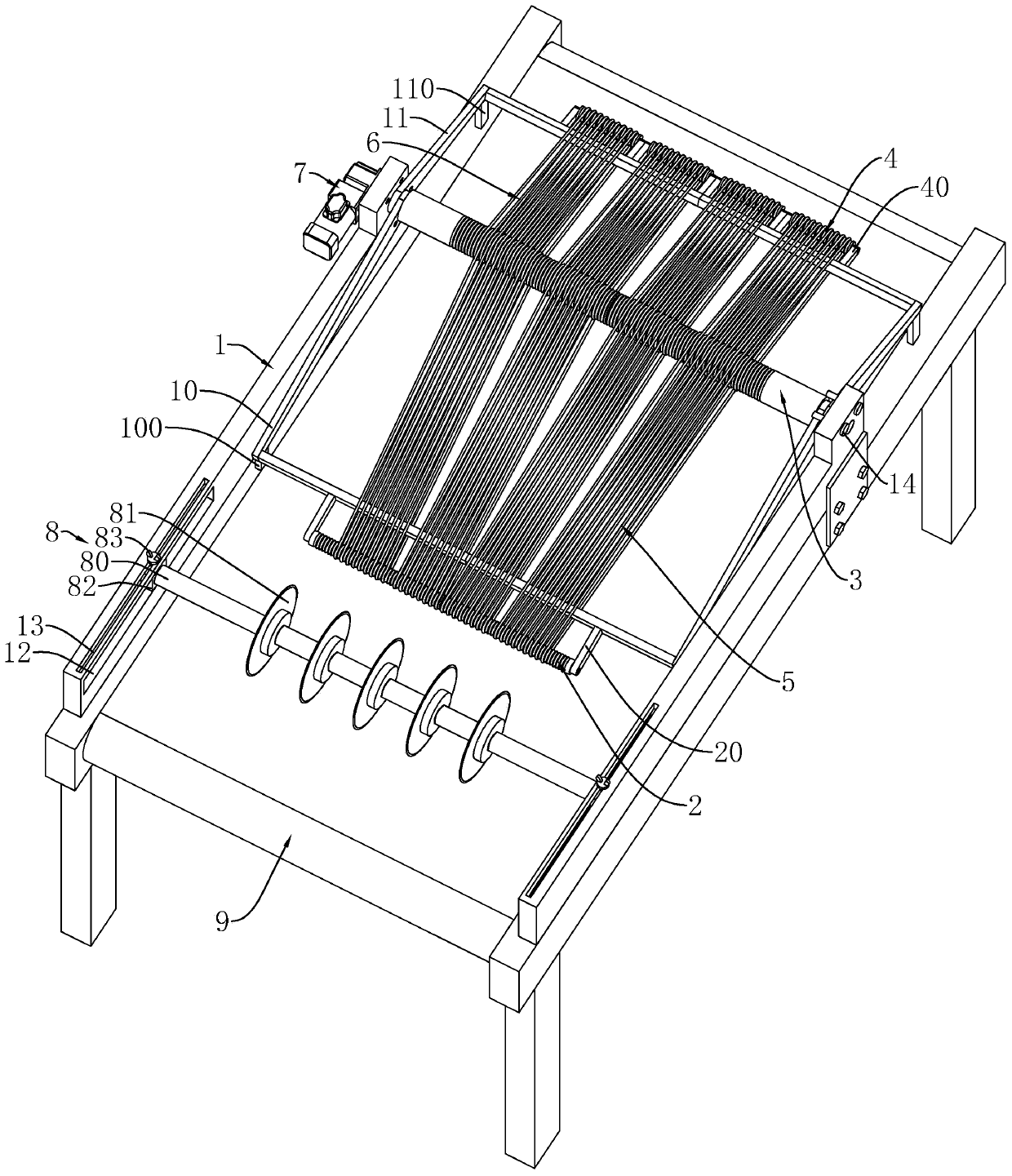

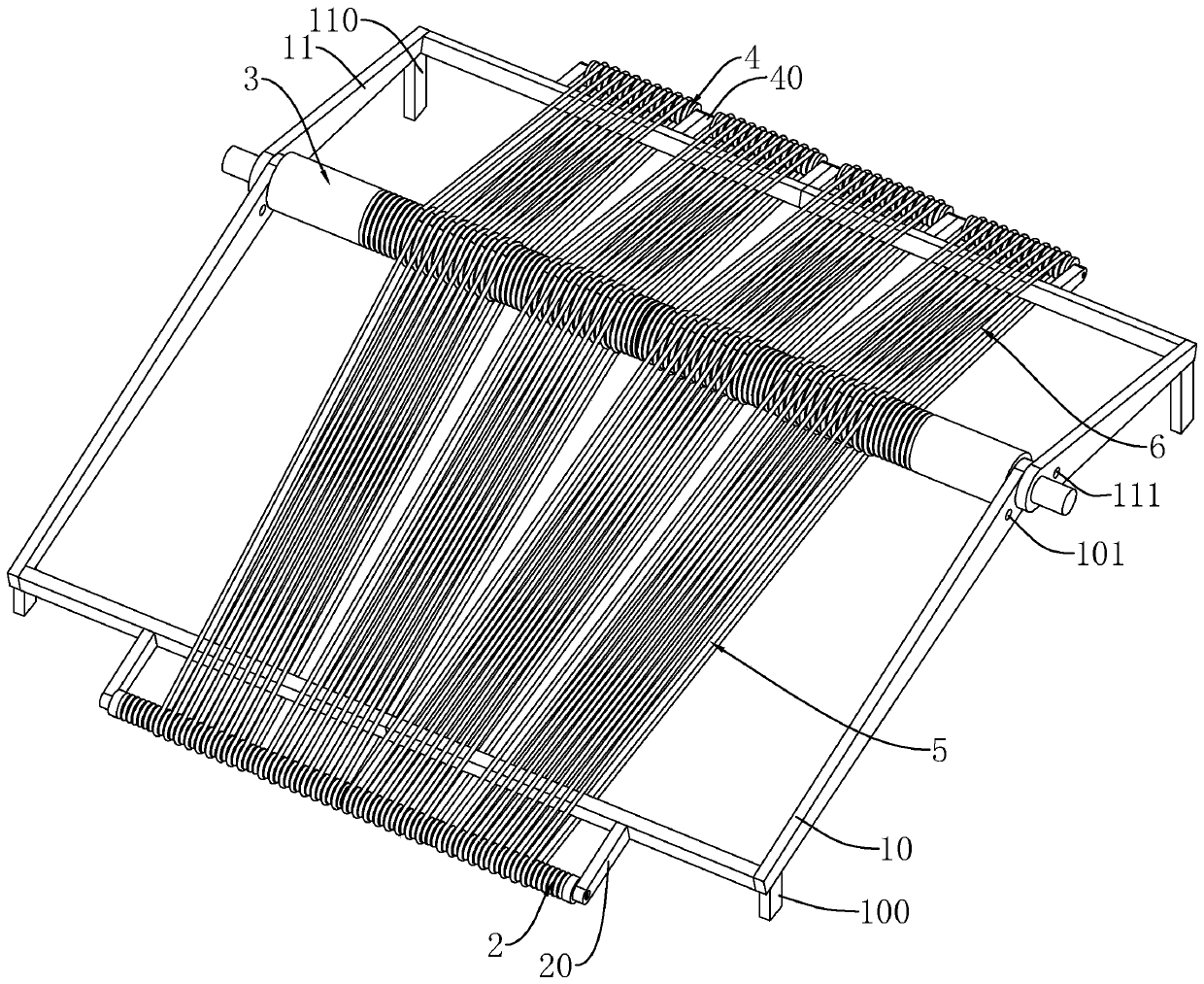

[0032] refer to figure 1 , figure 2 , is a kind of noodle strip splitting and laminating machine disclosed in the present invention, which is arranged on the conveyor belt 9 and used in conjunction with the conveyor belt 9, and it includes a frame body 1 .

[0033] Frame body 1 is arranged on the conveyor belt 9 top and is fixed on the frame of conveyor belt 9; A first frame 10 is connected horizontally to the frame body 1 . The lower part of the first frame 10 on the side away from the axis of rotation is fixedly connected with two entrance pillars 100 . The lower ends of the entrance pillars 100 are supported on the frame of the conveyor belt 9 . A second frame 11 is horizontally rotatably connected to the frame body 1. The rotation axis of the second frame 11 coincides with the rotation axis of the first frame 10. The second frame 11 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com