An automatic packing production line for square bricks

A production line, automatic technology, applied in packaging, building materials packaging, transportation and packaging, etc., can solve the problems of inability to limit the staggered movement of bricks and balers, complex belt transmission structure, increase the clamping force of balers, etc., to improve the storage space. Effectiveness of utilization rate, improving packaging quality, and facilitating forklift transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the technical solution of the present invention more clearly, the structure and functions thereof will be described in detail below in conjunction with the accompanying drawings. Obviously, what is described below is only a specific embodiment of the present invention.

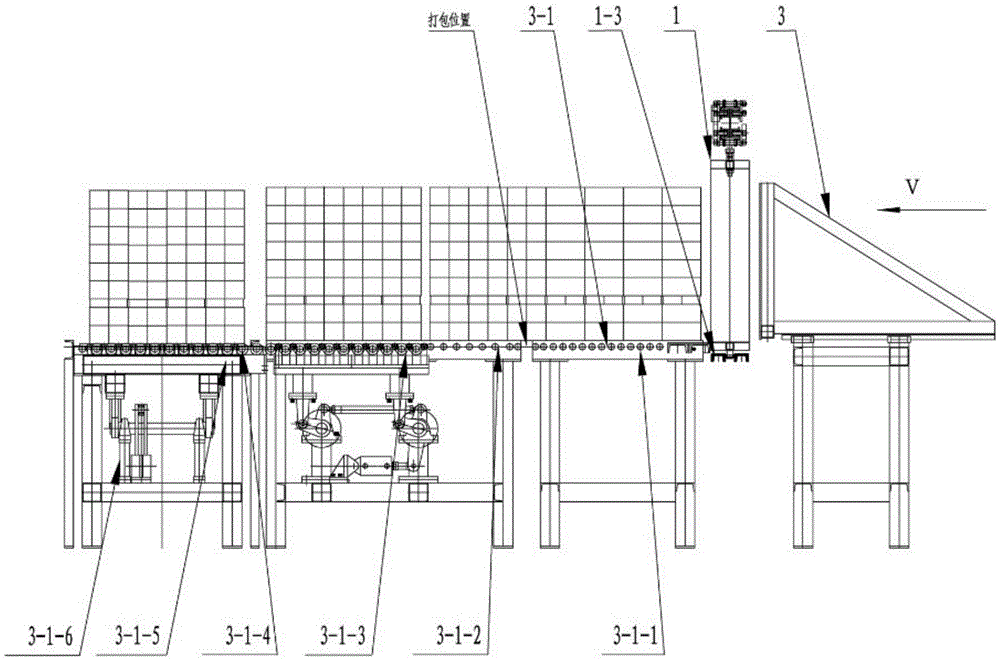

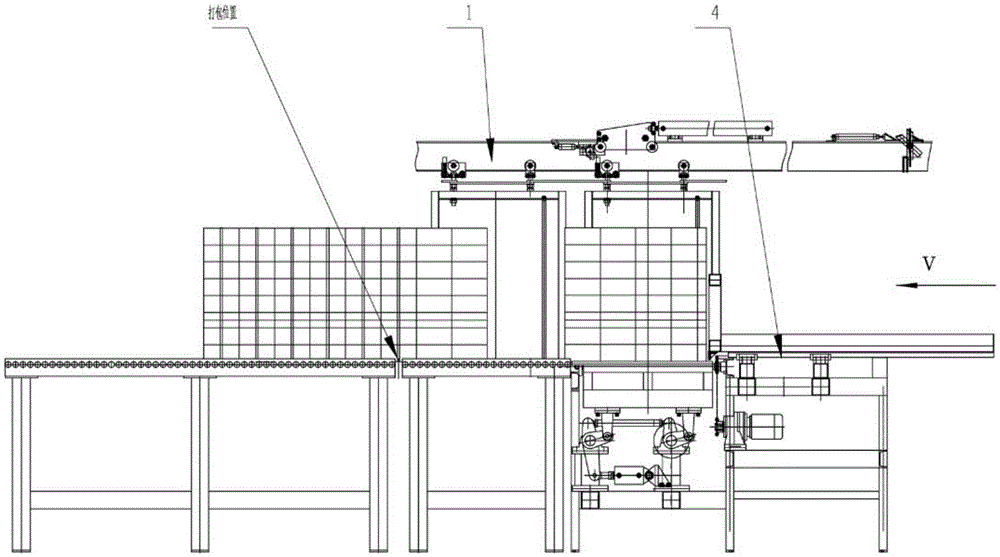

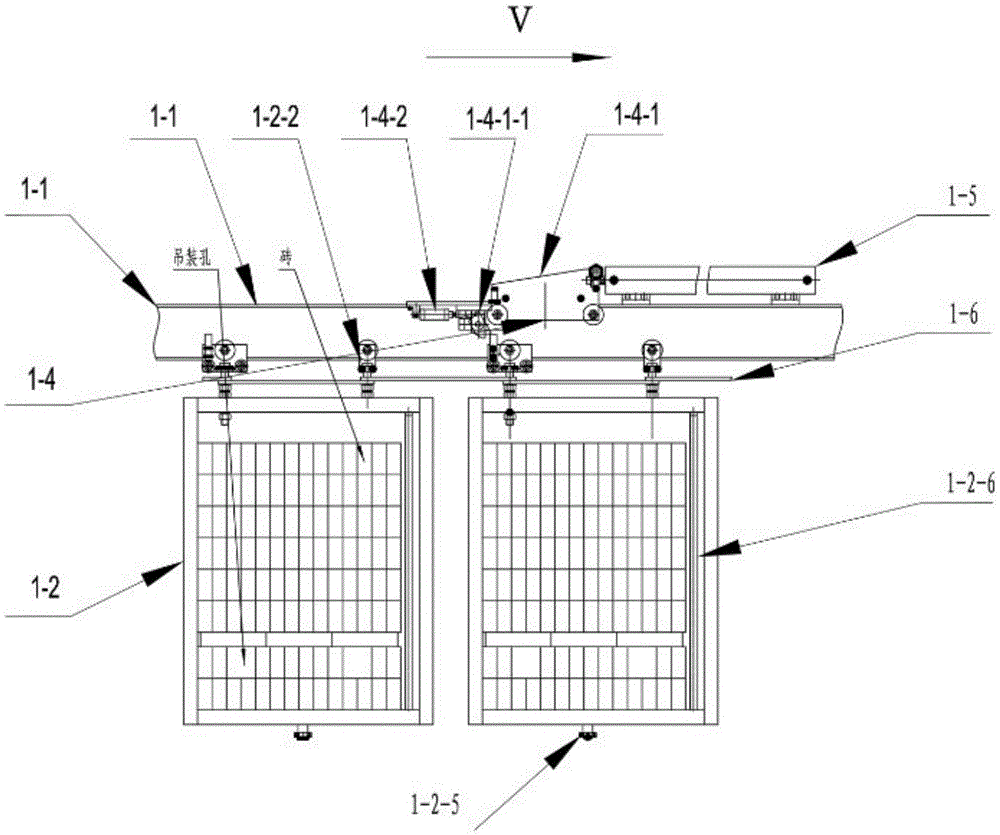

[0030] like figure 1 As shown in Figure 8, an automatic packing production line for square bricks includes a circular feeding system 1, a brick pushing mechanism 2, a brick stack longitudinal packing system 3, a brick stack horizontal packing system 5 and an automatic detection control system (not shown in the figure). , PLC control system is used in this embodiment); wherein, the circulating feeding system 1 is used to provide brick materials to the longitudinal packing system 3, straddles two kiln cars (not shown in the figure), and is arranged on the brick The feeding end of the vertical packing system 3 of the stack; the brick pushing mechanism 2 is used to push the stack of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com