Multi-terminal industrial equipment inspection monitoring system and method based on digital twinning technology

A monitoring system and industrial equipment technology, which is applied in the field of multi-terminal industrial equipment inspection and monitoring system, can solve the problems of fault feedback delay, poor visualization of fault data, etc., and achieve the effect of improving operation and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

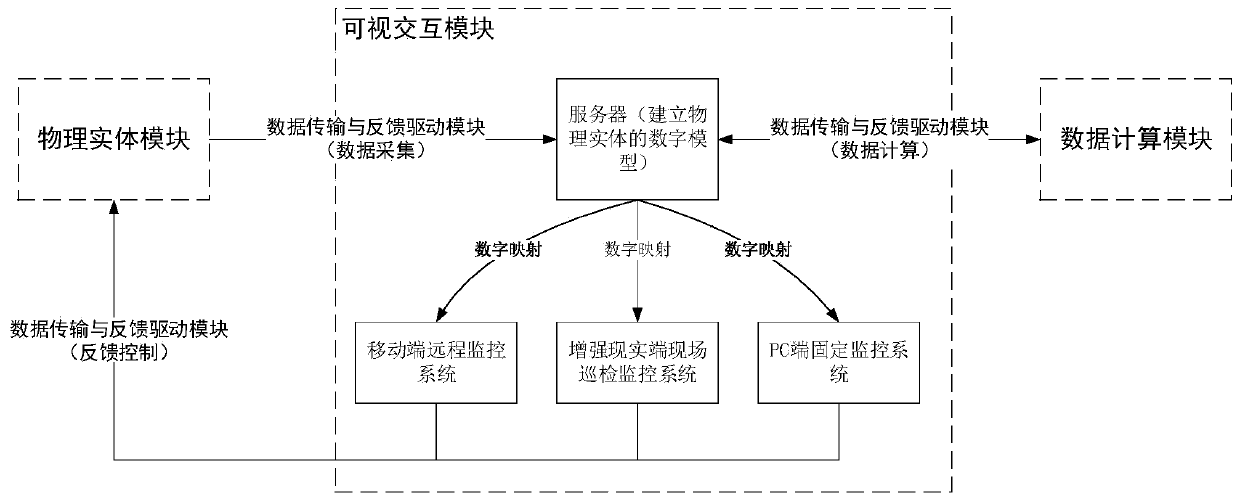

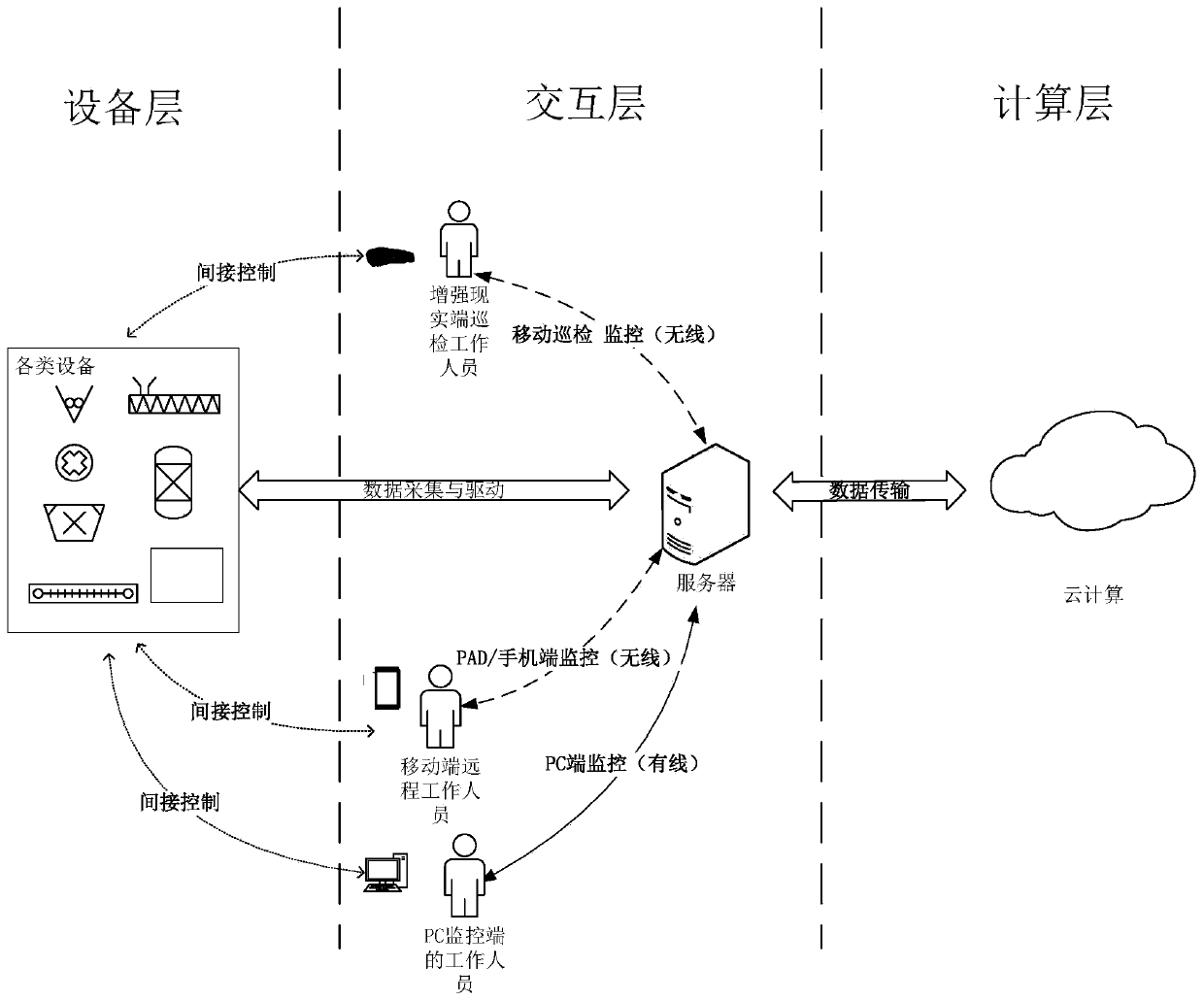

[0057] This embodiment provides a technical solution: a multi-terminal industrial equipment inspection and monitoring system based on digital twin technology, including a physical entity module, a visual interaction module, a data calculation module, and a data transmission and feedback drive module;

[0058] The visual interaction module includes a server, a PC fixed terminal monitoring system, an augmented reality terminal on-site inspection and monitoring system, a mobile terminal remote monitoring system, the PC fixed terminal monitoring system, the augmented reality terminal on-site inspection and monitoring system, all The mobile terminal remote monitoring system is respectively connected with the server;

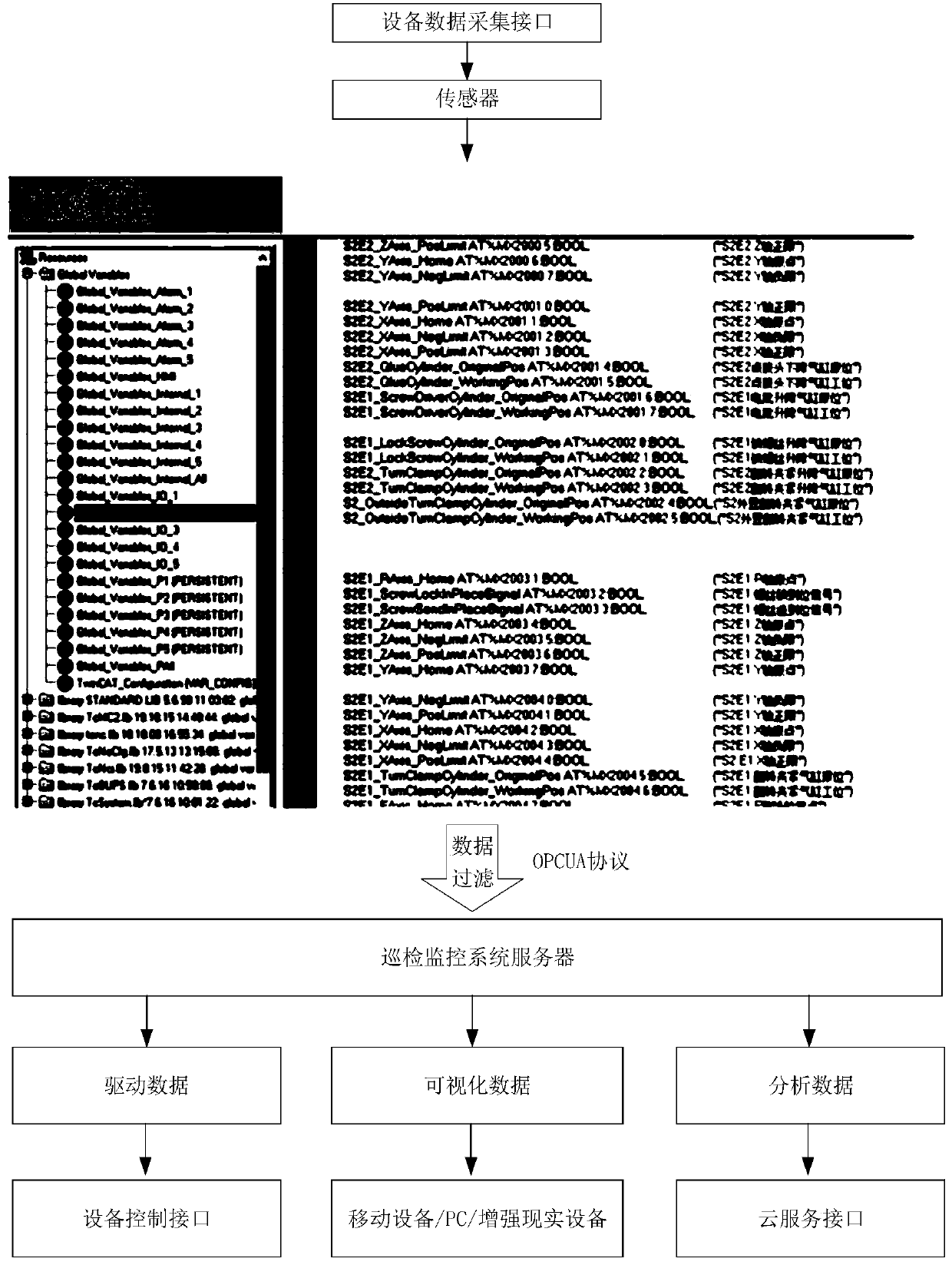

[0059] The physical entity module, as the basic module of the entire production inspection and monitoring system, that is, the entity of equipment operation, needs to install sensors, extract equipment status data, and transmit it to the server of the visual interactio...

Embodiment 2

[0084] Such as figure 1 As shown, it is the schematic diagram of the architecture of the inspection and monitoring system. The system obtains the data of the equipment through the sensor, collects it through the PLC, and finally transmits it to the server through the OPCUA data protocol. The server is a collection point of data, and it will separate various data It is transmitted to the data computing terminal, interactive control terminal and equipment control terminal through wired and wireless methods. The server is divided into data acquisition server and visualization server.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com