Thick film photoresist composition containing carboxyl phenolic resin with high heat resistance

A phenolic resin and high heat-resistant technology, applied in the field of functional polymer materials, can solve the problems of increasing exposure time and developing time, reducing processing efficiency, and decreasing sensitivity, and achieve shortening developing time, improving processing efficiency, and low methylene The effect of proportion

Pending Publication Date: 2020-05-19

SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

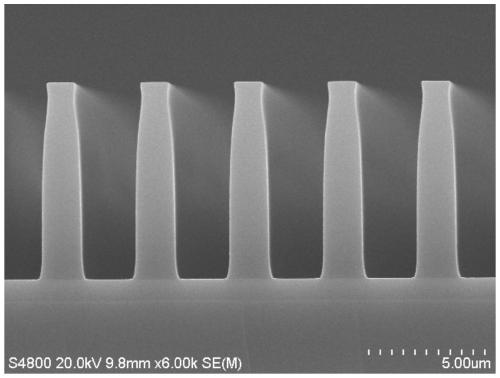

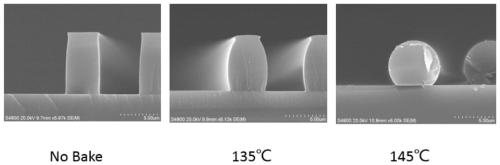

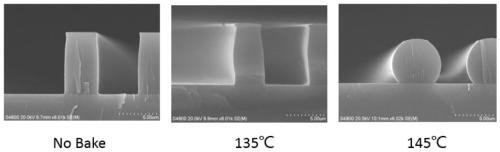

Due to the thicker film thickness, the sensitivity decreases, the exposure time and development time are increased, and the processing efficiency is reduced; various heat treatments will be implemented in the manufacturing process, and insufficient heat resistance will cause the pattern to collapse; when etching high aspect ratio patterns, photolithography is required Resist has high etch resistance, how to balance photosensitivity, heat resistance, etch resistance has become an important development direction of thick film photoresist

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0033] Example 1: polycondensate of m-cresol, p-cresol, 2,4-dimethylphenol and formaldehyde, Mw=8579g / mol, ADR is 230 Angstroms / second.

Embodiment 2

[0034] Example 2: polycondensate of m-cresol, p-cresol, 2,5-dimethylphenol and formaldehyde, Mw=9785g / mol, ADR is 170 angstroms / second.

Embodiment 3

[0035] Example 3: polycondensate of m-cresol, p-cresol, 2,4-dimethylphenol, 2,5-dimethylphenol and formaldehyde, Mw=9784g / mol, ADR is 212 angstroms / second.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a thick film photoresist composition containing carboxyl phenolic resin with high heat resistance. The structural general formula of the carboxyl phenolic resin with high heatresistance is shown in the specification, wherein x is 0-4, the ratio of m to n is 0.05-0.75: 1, R is H, phenyl or C1-C9 alkyl, and the weight-average molecular weight of the resin is 8000-35000g / mol.The film-forming resin is mixed with commercial phenolic resin, a photosensitive compound, an additive, a solvent and other components to obtain the thick film photoresist composition. Tests show that the thick film photoresist composition is high in resolution ratio, high in sensitivity, good in heat resistance and excellent in etching resistance, and is suitable for MEMS processing and packaging processes with high heat resistance requirements.

Description

technical field [0001] The invention relates to the technical field of functional polymer materials, in particular to a thick-film photoresist composition prepared by using high heat-resistant carboxyl phenolic resin as a film-forming resin. Background technique [0002] Micro-electro-mechanical systems (MEMS), also known as micro-electro-mechanical systems, micro-systems, micro-machines, etc., refer to high-tech devices with a size of a few millimeters or even smaller. MEMS is an independent intelligent system whose internal structure is generally on the order of microns or even nanometers. MEMS is developed on the basis of microelectronics technology (semiconductor manufacturing technology), and integrates high-tech electronic machinery produced by technologies such as lithography, corrosion, thin film, LIGA, silicon micromachining, non-silicon micromachining and precision machining. device. The MEMS fabrication method is accomplished by multiple photolithography and rel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G03F7/039

CPCG03F7/0392

Inventor 纪昌炜郑祥飞徐亮

Owner SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com