Gear pair of stable non-pulse gear pump and machining technology of gear pair die cavity

A technology without pulses and gear pairs, which is applied to pumps, pump components, rotary piston pumps, etc., to achieve the effects of increasing life, stabilizing the medium, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

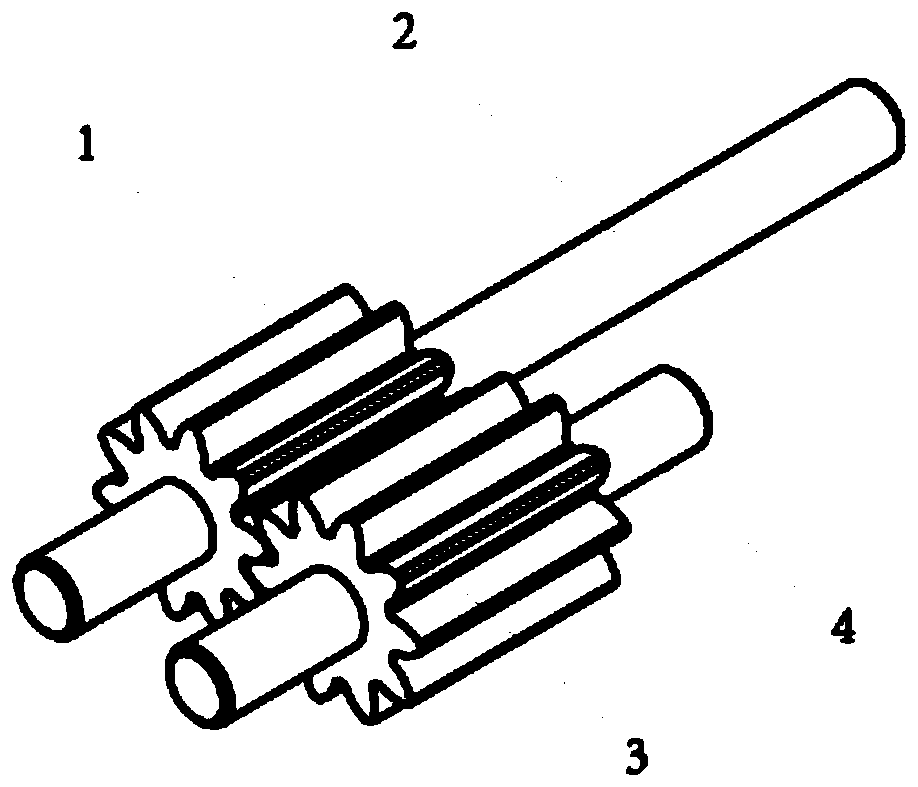

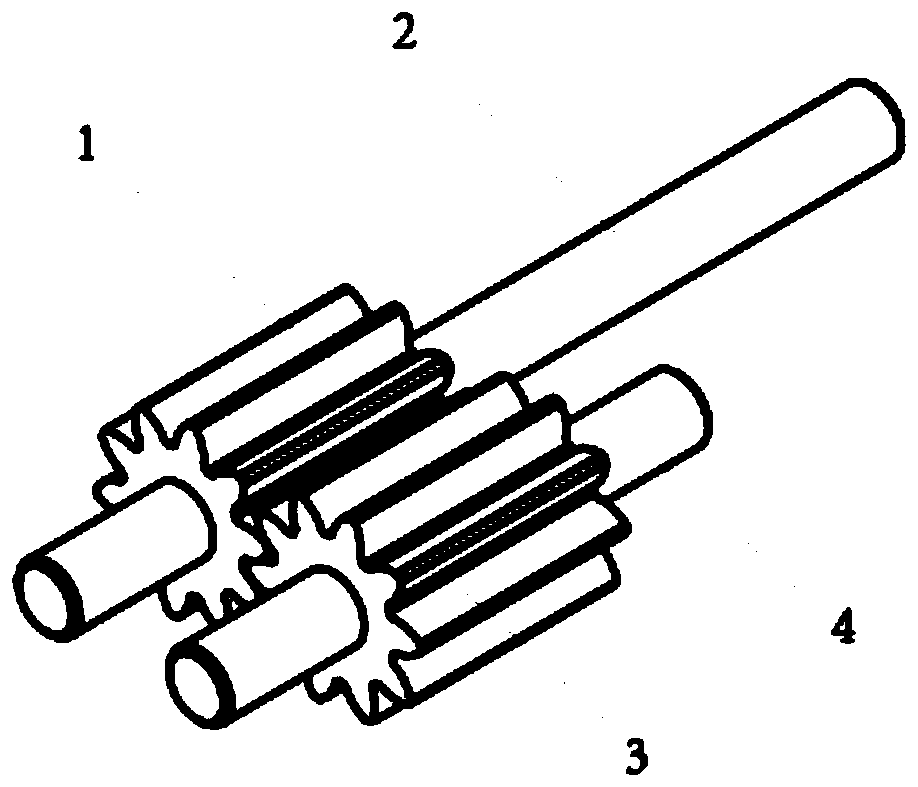

[0023] See attached figure 1 As shown, the gear pair of a smooth pulse-free gear pump in this embodiment is an involute spur gear pair, including a driving gear 1 and a driven gear 3 meshing with each other, and the driving gear 1 is provided with a main drive shaft 2 , The driven gear 3 is provided with a slave drive shaft 4 . Among them: the parameters of driving gear 1 and driven gear 3 are the same, and the design parameters are as follows:

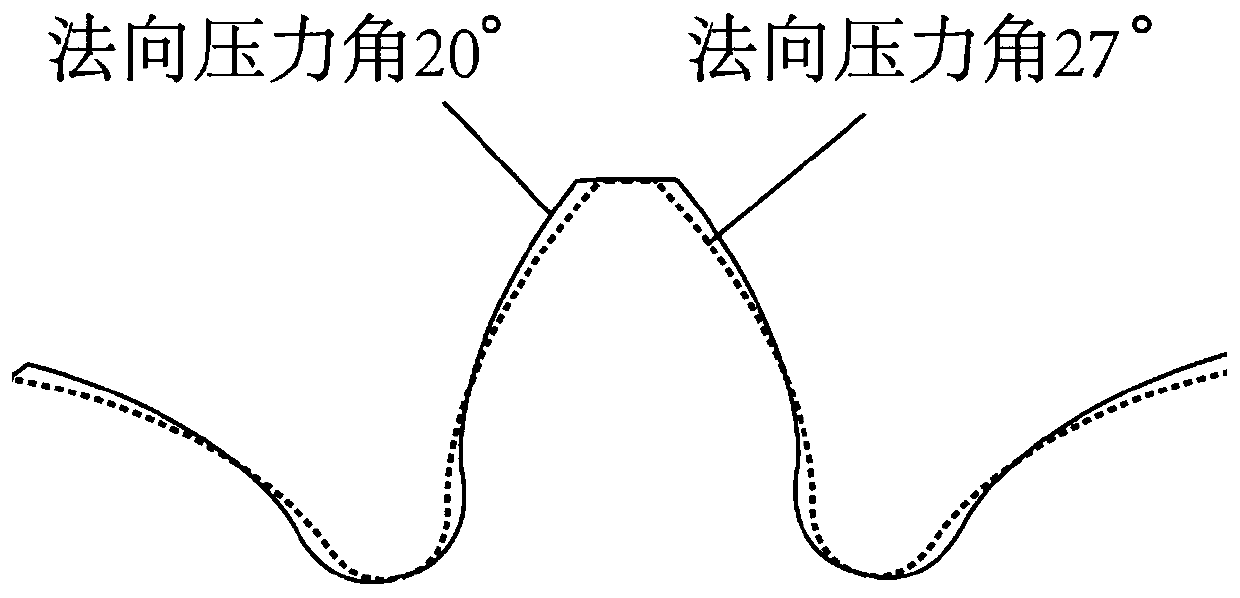

[0024] The number of teeth is 10-18, the normal phase modulus is 1-20mn, the normal pressure angle is 20°, the addendum height coefficient is 0.8, the dedendum height coefficient is 1.26, the meshing angle is 29.531°, and the tooth shape coincidence degree is 1.024.

[0025] In this embodiment, the driving gear with 10 teeth is taken as an example, and its basic parameters are as follows:

[0026] Speed(r / min) 1000 Number of teeth z 10 Normal modulus mn 1 Addendum height factor ha* 0.8 Dedend height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com