A torque sensor calibrating method

A technology of torque sensor and calibration method, applied in the field of sensor measurement, can solve the problems of complicated calibration operation, high cost, poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

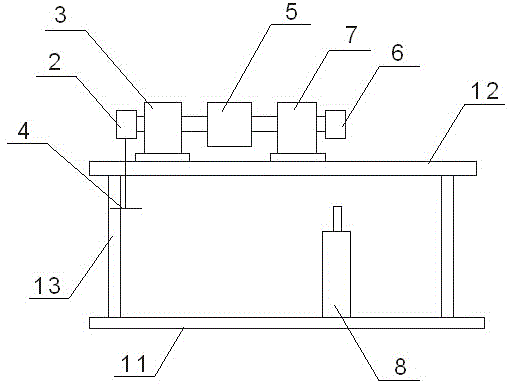

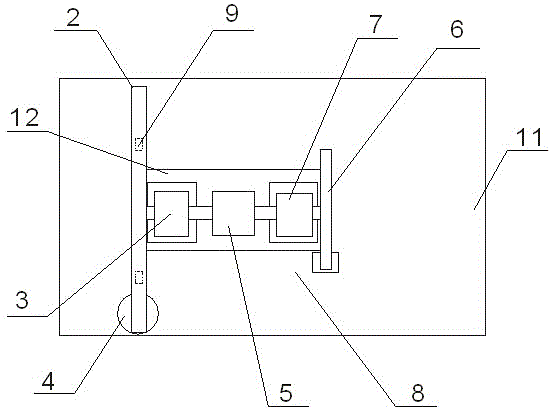

[0035] Example: see figure 1 , figure 2 , a torque sensor calibration method, in the calibration process need to use a special calibration bench, the calibration bench includes a mounting base, a loading arm 2, a long arm mounting seat 3, a weight tray 4, a torque sensor to be calibrated 5 , Leveling jib 6, jib mount 7 and leveling cylinder 8. The installation base includes a base plate 11 , an installation base plate 12 and a support rod 13 connecting the installation base plate 12 and the base plate 11 ; wherein, the width of the base plate 11 is greater than that of the installation base plate 12 . The long arm mounting seat 3 is fixed on one end of the mounting base plate 12, and the long arm bearing seat is fixed on the long arm mounting seat 3, and the middle part of the loading long arm 2 is connected with (one end of) the long arm connecting shaft. The long arm connecting shaft is installed on the long arm bearing seat through the long arm connecting bearing. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com