Modular combined underground engineering tunneling device and construction method thereof

An underground engineering, combined technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of too many sections of underground engineering, unable to correspond to unity, single section of tunneling equipment, etc., to reduce the cost of underground engineering and increase mechanization degree, the effect of good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

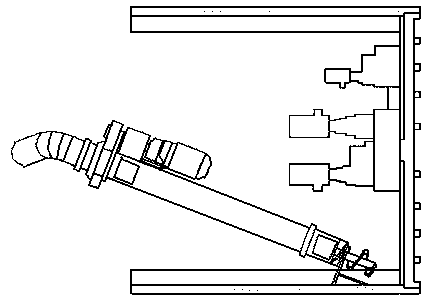

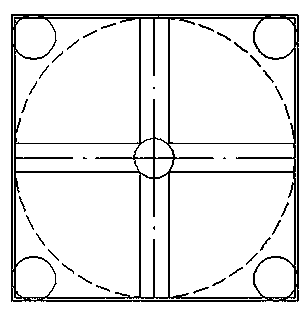

[0058] For the underground walkway, the tunneling device of the present invention is used for construction. according to image 3 The schematic cross-section of the outline of the underground pedestrian passage is divided according to the above three standard excavation units. Specifically, type I excavation units and type III excavation units are selected, one type III excavation unit is arranged in the middle, and 10 type I excavation units are arranged The units are arranged on both sides respectively, so as Figure 4 The schematic diagram of the excavation unit modulus of the underground municipal tunnel is shown, and the combination of the two can be obtained as Figure 5 The cross-sectional schematic diagram of the combined roadheader for the underground walkway shown.

Embodiment 2

[0060] Taking the underground municipal tunnel as an example, the tunneling device of the present invention is used for construction. according to Figure 6 The schematic diagram of the outline section of the underground municipal tunnel shown is divided according to the above three standard excavation units. Specifically, type I excavation units, type II excavation units and type III excavation units are selected, and two type III excavation units are arranged in the lower left corner. Arrange 5 type II excavation units on top of 2 type III excavation units, then arrange 10 type I excavation units on top of 5 type II excavation units, finally arrange 8 type I excavation units on the last right side, get as Figure 7 The schematic diagram of the excavation unit modulus of the underground municipal tunnel is shown, and the combination of the two can be obtained as Figure 8 The cross-sectional schematic diagram of the combined roadheader for the underground municipal tunnel s...

Embodiment 3

[0062] For the subway station at the intersection, adopt the driving device of the present invention to carry out construction.

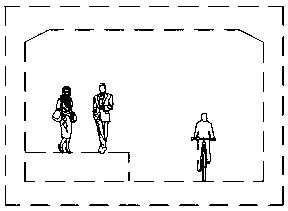

[0063] Process one: if Figure 9 As shown, a subway station is planned to be built at the crossroad 6 position, and the shaft 7 needs to be constructed on both sides of the road earlier.

[0064] Process two: if Figure 10 shown. In the vertical shaft 7, the construction cross channel 8 is dug underground. The cross-sectional schematic diagram of the cross-channel is shown in Figure 11 , specifically select Type I tunneling units, Type II tunneling units, and Type III tunneling units, arrange three rows and two columns of Type III tunneling units in the lower left corner, and arrange five Type II tunneling units corresponding to the two Type III tunneling units on the top row On the top of the excavation unit, arrange 8 type II excavation units on the far right, and finally arrange two type I excavation units on the right side above the type II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com