A method for removing the inner shielding layer of anodized aluminum channel

A technology of anodized aluminum and inner shielding layer, applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problems of unfavorable electroplating process, undisclosed etching method, non-uniform corrosion, etc., and achieve simple and easy positioning corrosion , good wash-off, high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] First, the preparation method of γ-chloropropyltrichlorosilane used in Example 1-3 is as follows: Take a 1000mL three-necked flask, mix 4.5M trichlorosilane and 3M 3-chloropropene in a constant pressure dropping funnel, Put about 25mL of feed liquid into reaction bottle earlier, then add 0.1mol / L chloroplatinic acid-isopropanol solution 0.15mL, cocatalyst 0.15mL, hydroquinone 0.25g, reaction is triggered rapidly at room temperature, is heated up to Start dropping the feed solution at 75°C, adjust the dropping rate and control the temperature at 80°C, complete the dropwise addition in about 2 hours, then reflux for 3 hours, and end the reaction when the reaction temperature finally rises to 90°C. The reaction mixture was fractionated under normal pressure, and the fraction at 182°C was collected, which was 3-chloropropyltrichlorosilane.

[0091] Secondly, the used pretreatment solution of embodiment 1-3 is consistent, all comprises mechanical polishing-degreasing-hot wat...

Embodiment 2

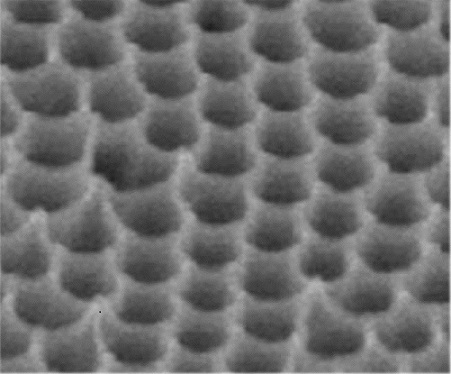

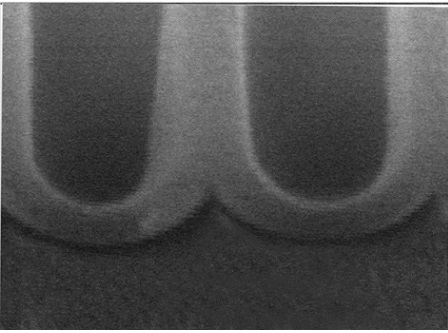

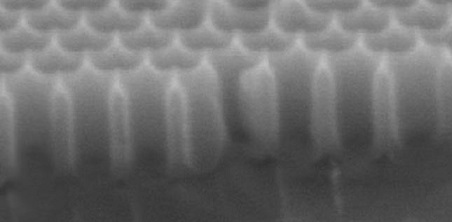

[0100] (2) Anodizing: use the aluminum material treated in step (1) as the anode, graphite as the cathode, immerse in the electrolyte, and connect the power supply through wires respectively. The electrolyte is a mixture of oxalic acid, phosphoric acid and sulfosalicylic acid , the concentration of oxalic acid is 0.275M, the concentration of phosphoric acid is 0.3M, the concentration of sulfosalicylic acid is 0.1M, the electrolysis parameters are as follows, the voltage is 25V, the temperature is 30 o C, current density 2.5A / dm 2 , time 25min; after anodizing, soak and clean in ethanol, and use vacuum drying to remove the electrolyte in the oxide film. The whole process strictly avoids the aluminum after anodizing from contacting air or water to avoid sealing holes.

[0101] (3) Protective film for positioning marks: Soak the aluminum material treated in step (2) in a toluene solution of γ-chloropropyltrimethylsilane, the concentration is 15wt.%, and the amount is 1% of the we...

Embodiment 3

[0104] (2) Anodizing: use the aluminum material treated in step (1) as the anode, graphite as the cathode, immerse in the electrolyte, and connect the power supply through wires respectively. The electrolyte is a mixture of oxalic acid, phosphoric acid and sulfosalicylic acid , the concentration of oxalic acid is 0.275M, the concentration of phosphoric acid is 0.3M, the concentration of sulfosalicylic acid is 0.1M, the electrolysis parameters are as follows, the voltage is 25V, the temperature is 30 o C, current density 2.5A / dm 2 , time 25min; after anodizing, soak and clean in ethanol, and use vacuum drying to remove the electrolyte in the oxide film. The whole process strictly avoids the aluminum after anodizing from contacting air or water to avoid sealing holes.

[0105] (3) Protective film for positioning marks: Soak the aluminum material treated in step (2) in a toluene solution of γ-chloropropyltrimethylsilane, the concentration is 15wt.%, and the amount is 1% of the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com