Hyperbranched polymer as well as preparation method and application thereof

A hyperbranched polymer and reaction technology, which is applied in the field of petroleum additives, can solve the problems that the demulsification efficiency needs to be improved, and achieve the effects of efficient demulsification, improved demulsification efficiency, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

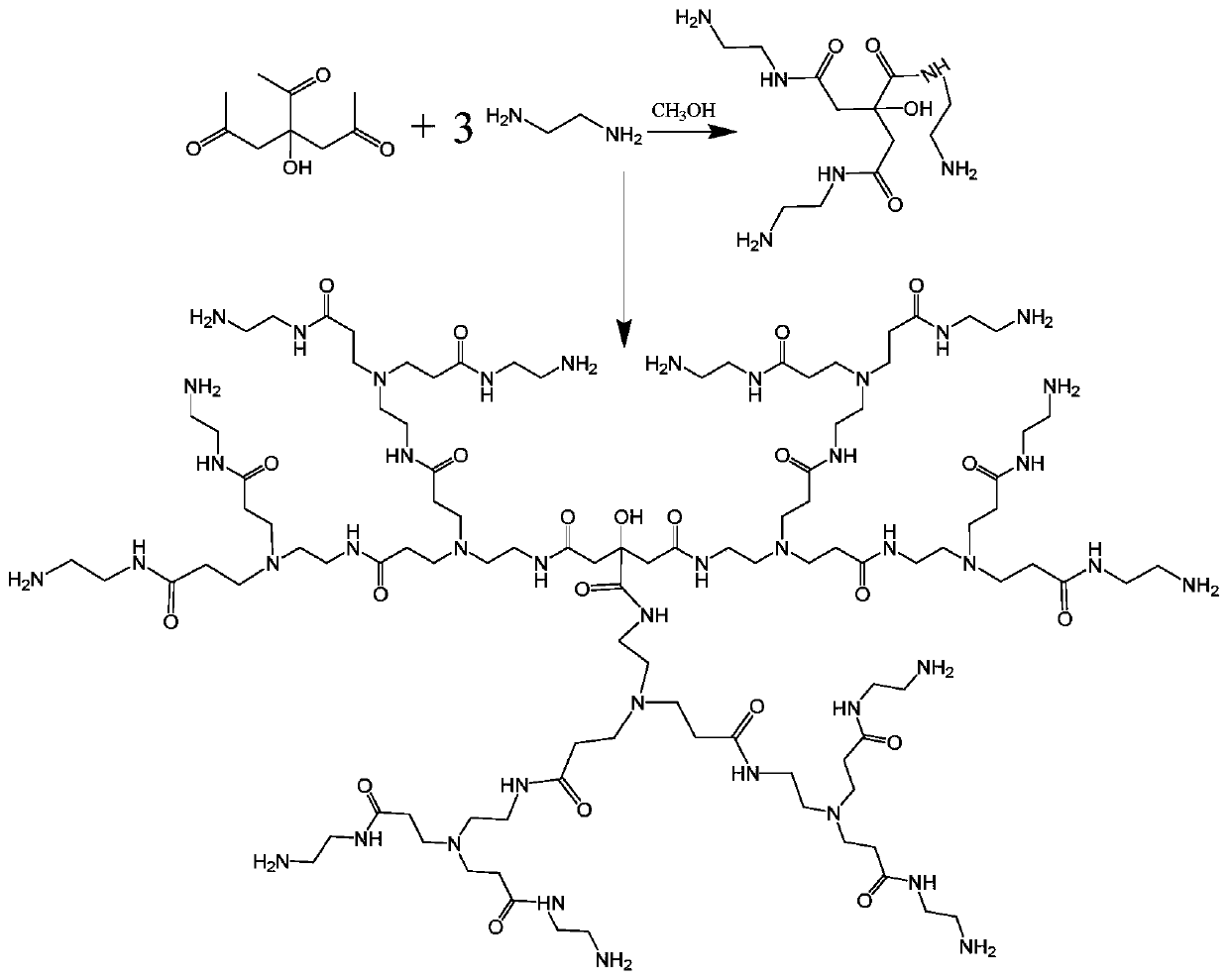

[0023] The concrete preparation method of this hyperbranched polymer comprises the steps:

[0024] (1) dissolving trimethyl citrate in a solvent, adding ethylenediamine thereto, and reacting at normal temperature to obtain intermediate 1;

[0025] (2) Add methyl acrylate and ethylenediamine to intermediate 1, react at room temperature, and then remove the solvent by distillation under reduced pressure to obtain intermediate 2;

[0026] (3) Under reduced pressure, the intermediate 2 was reacted with a gradient from 60 to 120° C. for 8 to 10 hours to obtain a reaction product. The reaction product was separated and dried to obtain the target product.

[0027] In some preferred embodiments of the present invention, the molar ratio of trimethyl citrate to ethylenediamine in step (1) is 1:3.

[0028] In some preferred embodiments of the present invention, the solvent used in step (1) is methanol.

[0029] In some preferred embodiments of the present invention, in step (1), trimet...

Embodiment 1

[0041]Embodiment 1 of the present invention provides a kind of preparation method of hyperbranched polymer, comprises the steps:

[0042] (1) 2.34g (0.01mol) of trimethyl citrate was dissolved in 30ml of methanol, then 1.8g (0.03mol) of ethylenediamine was added dropwise thereto, after mixing evenly, the mixed solution was placed at room temperature (25 °C) Stir the reaction at a rate of 300r / min for 24h to obtain intermediate 1;

[0043] (2) Add 9.02g (0.15mol) of ethylenediamine and 15.50g (0.18mol) of methyl acrylate to the intermediate 1 prepared in step (1), and continue stirring at a rate of 300r / min at room temperature Reaction for 24h, and then the solvent methanol was removed under reduced pressure to obtain intermediate 2;

[0044] (3) Under reduced pressure, react intermediate 2 at 60°C for 1h, 80°C for 1h, 100°C for 2h, and 120°C for 2h, naturally cool the obtained reaction product to room temperature, and add ether to the reaction product After stirring and prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| demulsification efficiency | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| demulsification efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com