Boron-containing fuel-rich propellant

A fuel-rich propellant and fuel technology, which is applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve the problem of low combustion efficiency, achieve the effect of improving combustion and promoting oxygen transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Test and Analysis of Thermal Oxidation Characteristics of Core-Shell Boron Powder

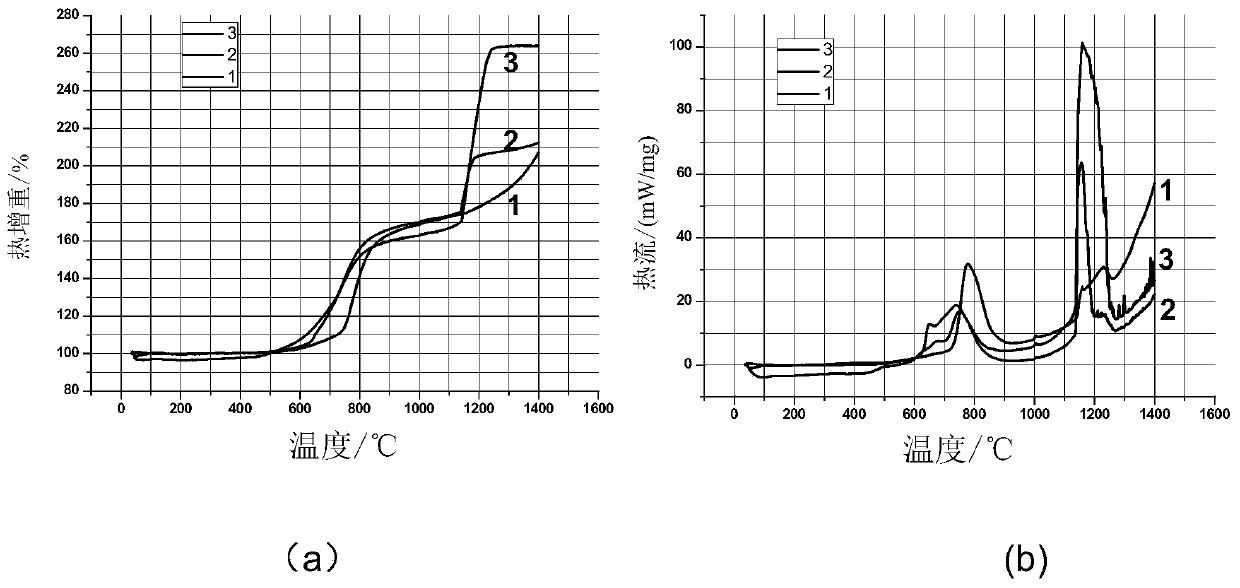

[0024] with Fe 2 o 3 As an example, the influence of transition metal oxide-coated boron powder on the thermal oxidation characteristics of boron powder is investigated, and the effect on B-Fe 2 o 3 The core-shell boron powder has been tested by TG-DSC thermal oxidation performance, and the results are as follows: figure 1 As shown, (a) is the TG curve of the sample, (b) is the DSC curve of the sample, and the curves 1, 2, and 3 marked in the figure represent the No. 1 sample, the No. 2 sample, and the No. 3 sample respectively. The sample is ordinary boron powder, the No. 2 sample is 5% Fe 2 o 3 Coated boron powder, sample No. 3 is 10% Fe 2 o 3 The coated boron powder was tested with a NETZSCH STA 449F3 thermal analyzer, the temperature range and temperature rise rate were 40°C / 20.0(°C / min) / 1400°C, and the atmosphere was 20OXYGEN 60NITROGEN. to B-Fe 2 o 3 The core-shell boron ...

Embodiment 2

[0029] B-Fe 2 o 3 Composition of core-shell boron powder: boron content 95%, Fe 2 o 3 Content 5%.

[0030] ⑴Propellant composition

[0031]

[0032] ⑵Propellant performance

[0033]

Embodiment 3

[0035] B-Cr 2 o 3 Composition of core-shell boron powder: boron content 95%, Cr 2 o 3 Content 5%.

[0036] ⑴Propellant composition

[0037]

[0038] ⑵Propellant performance

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com