A method of nanometer precision preparation using femtosecond laser

A femtosecond laser and nanotechnology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as limited process flow, yield and cost, limited focusing spot diffraction limit, and difficulty in meeting industrial mass production. , to achieve the effect of good processing compatibility, strong robustness, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Nano-patterns with birefringence are prepared on titanium dioxide by using femtosecond laser for nano-precision preparation.

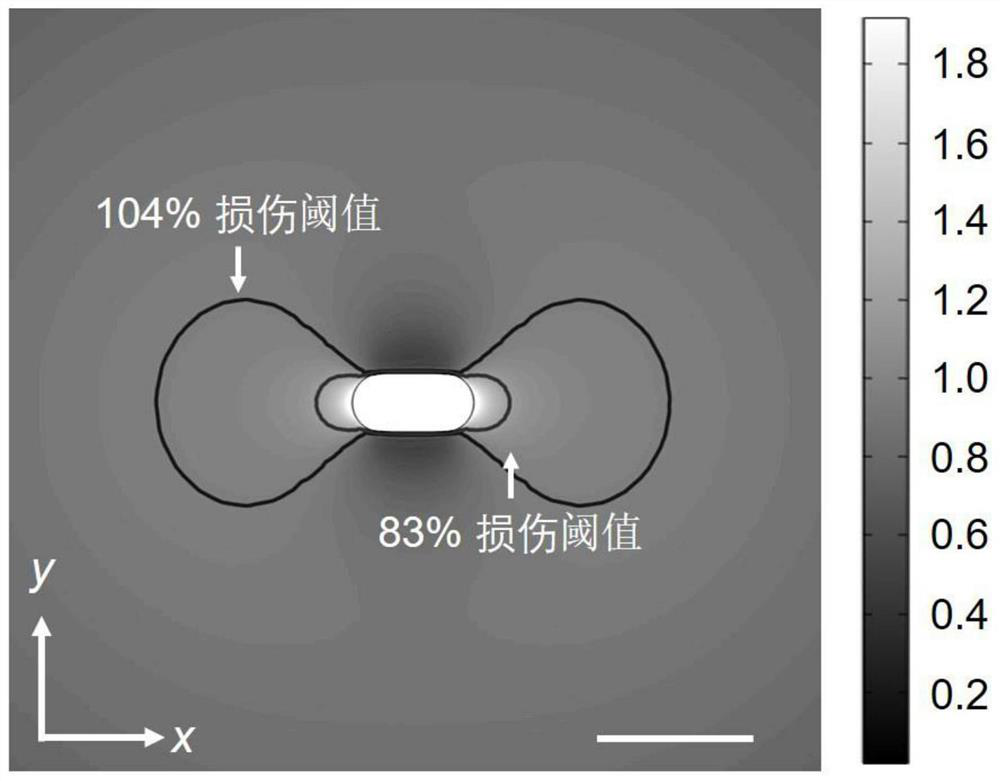

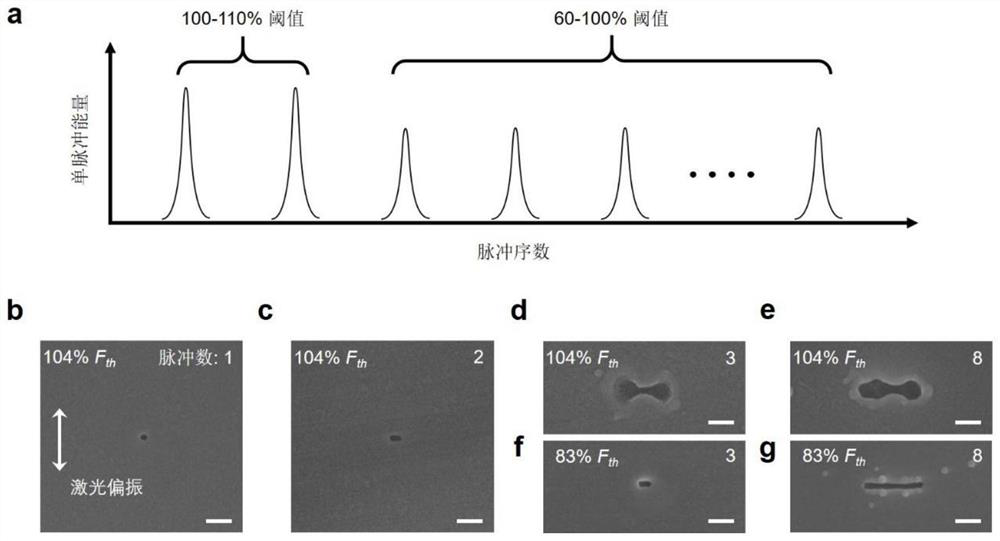

[0039] The initial damaged nanopore formed by femtosecond laser multiphoton excitation is used as a seed structure, and the energy and polarization state of subsequent laser pulses are adjusted in real time, so that uniform and directional optical near-field enhancement near the seed structure is used to achieve high-precision removal of processed materials. According to the geometric structure of the pre-designed nano-groove, the polarization state of the laser pulse is adjusted in real time, so that the nano-groove designed by the sum of the polarization of the laser pulse remains locally vertical, thereby preparing any given geometric pattern of the nano-groove.

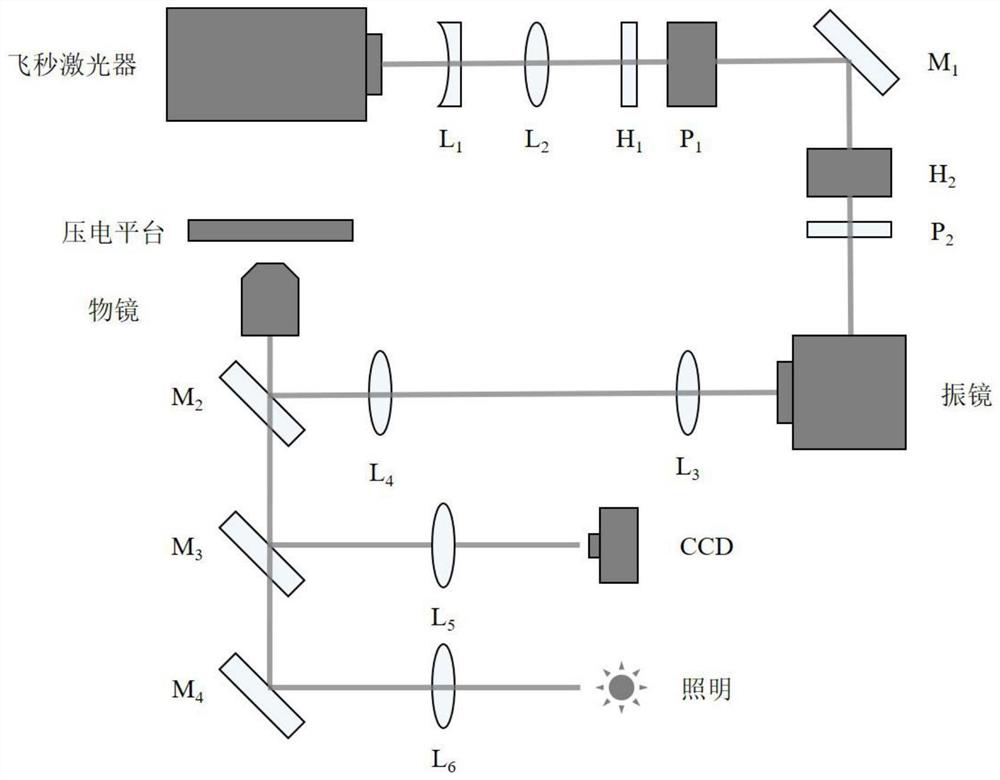

[0040] The method of preparing a nanometer pattern with birefringence on titanium dioxide by using a femtosecond laser to prepare nanometer precision, the specific steps are as follo...

Embodiment 2

[0055] A method for preparing periodic nano-grooves on the surface of titanium dioxide and quartz glass by using femtosecond laser for nano-precision preparation.

[0056] Large-area nanostructures of any given shape can be rapidly prepared by periodically depositing seed structures and adjusting the energy and polarization state of laser pulses in real time.

[0057] Fabrication of Periodic Nanogroove Arrays on TiO2 and Quartz Glass Surfaces:

[0058] (1) Leveling of samples;

[0059] Same as in Example 1, wherein the spot of the femtosecond laser is enlarged by 2 times after beam expansion.

[0060] (2), preparation of seed structure;

[0061] As in Example 1, it is enough to periodically prepare the seed structure on the surface of the sample.

[0062] (3) Raster scanning to prepare large-area nanostructures:

[0063]When machining on titanium dioxide surfaces, reduce the energy of the laser pulse to between 83% of the material damage threshold (for quartz glass, reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com