Titanium-nickel alloy material with high blood compatibility and preparation method thereof

A titanium-nickel alloy, compatible technology, used in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of reduced heparin activity, chemical pollution, and easy coating fall off by anticoagulant drug fixation. Fibrin adhesion, improved antibacterial properties, and improved adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

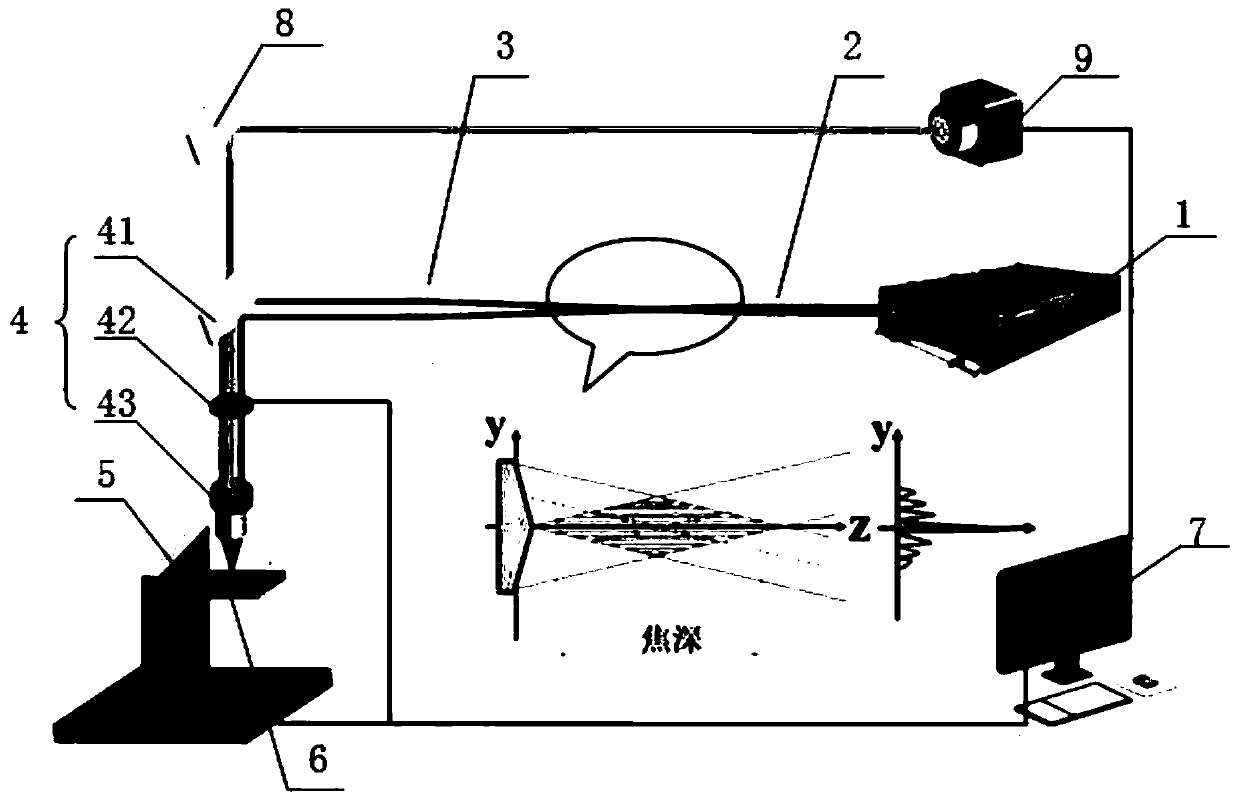

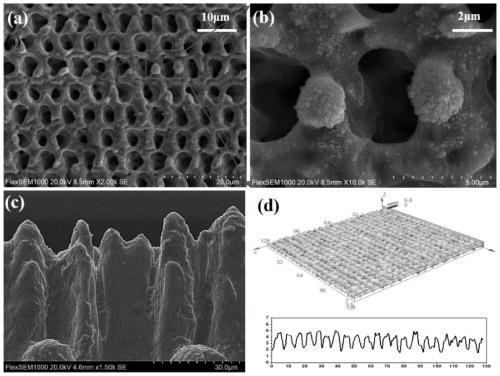

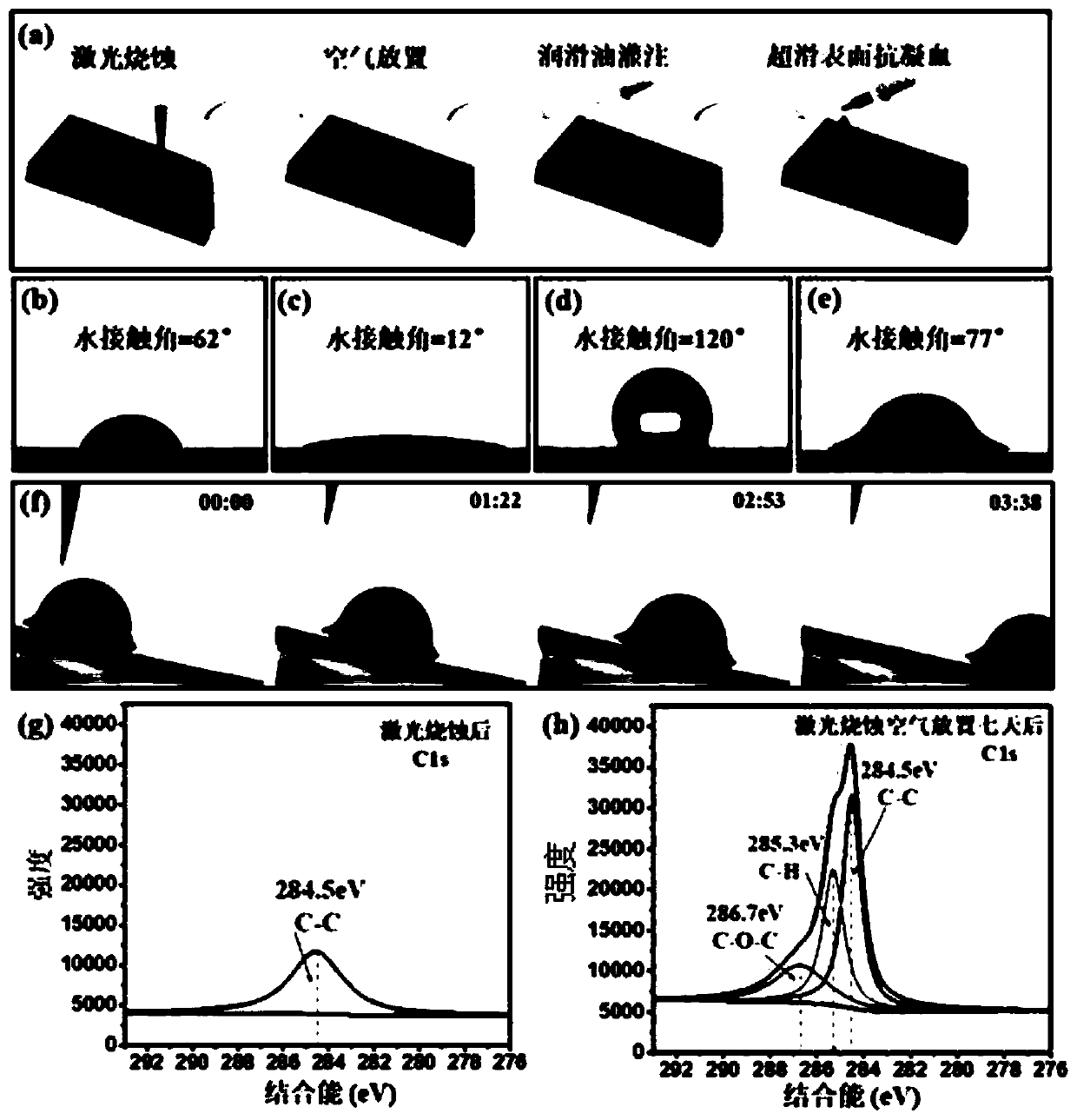

[0047] see figure 1 and image 3 In (a), the preparation method for preparing the above-mentioned highly blood-compatible titanium-nickel alloy material includes the following steps:

[0048] Step 1: The femtosecond laser 1 generates the femtosecond laser, and then the axicon lens 2 spatially shapes it into a conical light field distribution of the Bessel profile;

[0049] Step 2: The conical light field of the Bessel profile output by the axicon 2 is collimated by the first lens 3 to form a parallel laser beam, and then through the micromachining system 4, it is focused on the titanium laser beam fixed on the three-dimensional processing table 5. Nickel alloy material 6 surface;

[0050] Step 3: Control the movement of the three-dimensional processing table 5, and the beam focused on the surface of the titanium-nickel alloy material 6 processes a uniformly distributed porous structure on the surface of the titanium-nickel alloy material 6;

[0051] Step 4: inject lubricati...

specific Embodiment

[0054] (1) femtosecond laser 1 produces femtosecond laser, and its femtosecond laser is that wavelength is 1030nm, and pulse width is 400fs-10ps, and output frequency is the red light of 25KHz-5MHz; Then the model manufactured by Thorlabs is AX-250, The axicon lens 2 with the apex angle α of 1° is spatially shaped into a conical light field distribution with a Bessel profile; in this embodiment, the femtosecond laser 1 is a FemtoYL-40 laser, and in addition to selecting the FemtoYL-40 laser, you can also choose YSLP laser or other lasers; the specific parameters of femtosecond laser 1 are set as follows: the frequency is set to 2500KHz, the frequency is selected by the signal generator to 2KHz, the high level is triggered, the duty cycle is 20%, and the power is 2170mW;

[0055] (2) The conical light field of the Bessel profile output by the axicon 2 is collimated by the first lens 3 to form a parallel laser beam, and then through the micromachining system 4, it is focused on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com