Reverse-direct flotation method for siliceous-calcareous collophanite

A technology of collophosite and silicon-calcium, which is applied in the field of grinding and reverse flotation backwater utilization process of silica-calcium collophosphine, which can solve the problem of increased consumption of beneficiation reagents, increased dosage of collector reagents, tailings The problem of high inventory pressure in the ore warehouse can achieve the effect of saving flotation reagents, low dehydration cost and reducing grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

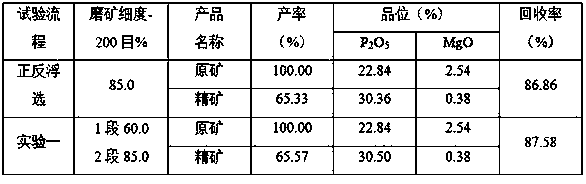

Embodiment 1

[0027]Embodiment 1, a method of reverse flotation of silicon-calcium colloidal phosphate rock. After the raw ore is ground, the flotation process is adopted first to remove magnesium by reverse flotation and then to remove silicon by positive flotation; the backwater of reverse flotation enters the reaction After the flotation backwater is returned to the reverse flotation to remove magnesium, the positive flotation backwater enters the positive flotation backwater and returns to the positive flotation desiliconization operation, and the surplus positive flotation backwater is fed into the reverse flotation backwater for reverse flotation Choose to use.

[0028] The method of this embodiment adopts stage grinding stage separation, the crushed raw ore is first fed into the first stage of grinding operation, and after the carbonate gangue ore is selected through the reverse flotation demagnesia operation, it is fed into the second stage of ore grinding operation , The ground pul...

Embodiment 2

[0029] Embodiment 2, a method for reverse flotation of siliceous calcareous colloidal phosphate rock, its specific steps are as follows:

[0030] (1) The crushed raw ore is fed into the first-stage grinding operation, and the grinding fineness of the first-stage grinding is -200 mesh and 75.00%; the ore pulp is fed into the reverse flotation demagnesiza- Flotation coarse concentrate dehydration operation, the filtrate is fed into the reverse flotation backwater tank; the foam product is sent to the tailings pond or tailings stockpile after dehydration operation, and the filtrate is fed into the reverse flotation backwater tank;

[0031] (2) The reverse flotation coarse concentrate filter cake after dehydration is sent to the second-stage grinding operation after slurry adjustment. The grinding fineness of the second-stage grinding is -200 mesh, accounting for 100%. Flotation desiliconization operation, the foam product is fed into the positive flotation coarse concentrate dehy...

Embodiment 3

[0038] Embodiment 3, a method for reverse flotation of siliceous calcareous colloidal phosphate rock, its specific steps are as follows:

[0039] (1) The crushed raw ore is fed into the first-stage grinding operation, and the grinding fineness of the first-stage grinding is -200 mesh and 65.00%; the ore pulp is fed into the reverse flotation demagnesiza- Flotation coarse concentrate dehydration operation, the filtrate is fed into the reverse flotation backwater tank; the foam product is sent to the tailings pond or tailings stockpile after dehydration operation, and the filtrate is fed into the reverse flotation backwater tank;

[0040] (2) The reverse flotation coarse concentrate filter cake after dehydration is sent to the second-stage grinding operation after slurry adjustment. The grinding fineness of the second-stage grinding is -200 mesh, accounting for 90%. Flotation desiliconization operation, the foam product is fed into the positive flotation coarse concentrate dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com