NiM-LDH/g-C3N4 composite photocatalytic material and preparation method thereof

A composite photocatalysis, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen/syngas production, etc. Low cost, good repeatability, enhanced separation efficiency and light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] High specific surface porous g-C 3 N 4 preparation of

[0027] Put 20 g of urea into a 50 mL crucible, cover it, put it into a muffle furnace, raise the temperature to 550 °C at a heating rate of 2 °C / min, keep the temperature for 4 h, and then cool it down to room temperature naturally. Take it out and grind it finely to get g-C with high specific surface porosity 3 N 4 Beige powder.

Embodiment 2

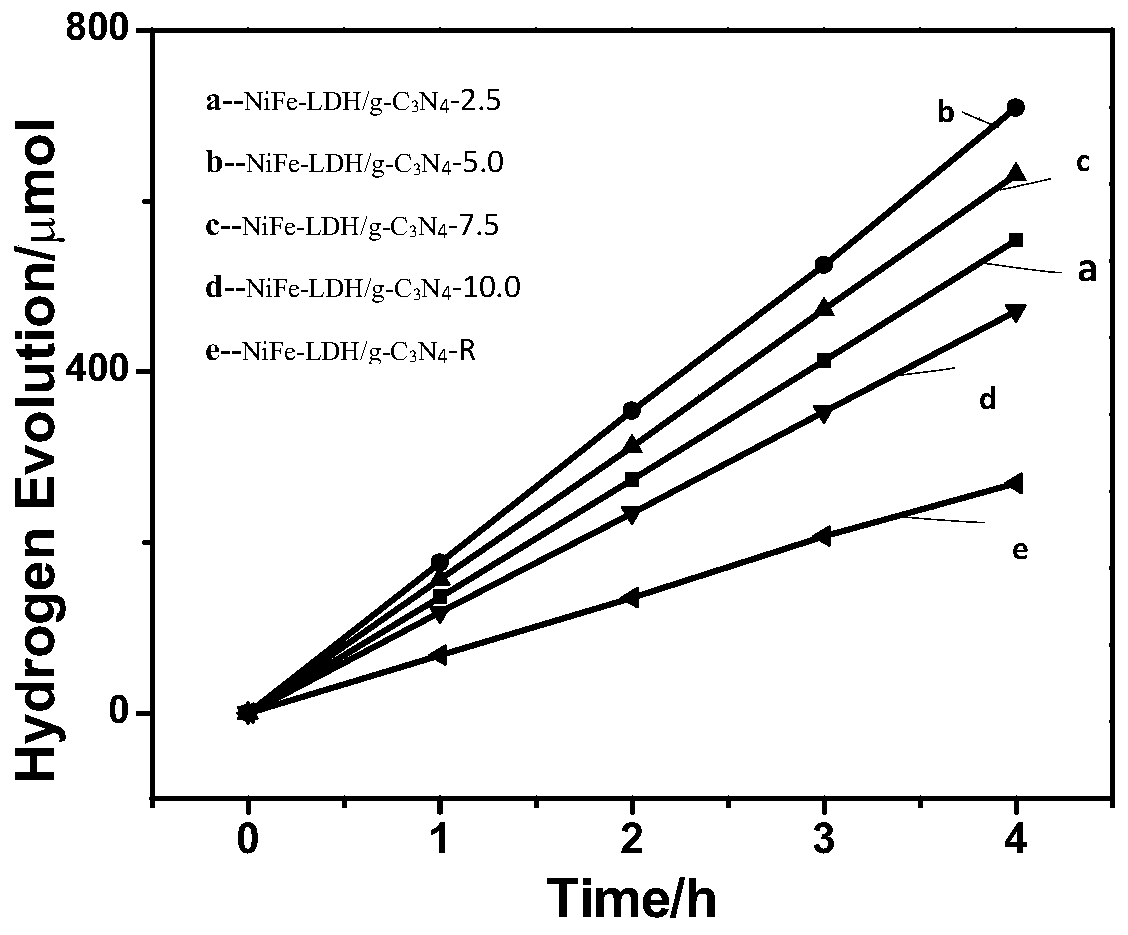

[0029] NiFe-LDH / g-C 3 N 4 -2.5 Preparation of two-dimensional ultrathin composite catalytic materials

[0030] Take by weighing 0.488g g-C prepared through embodiment 1 3 N 4 Put the powder in a polytetrafluoroethylene tank, add 25mL of n-butanol and 25mL of purified water, then add 100mg of urea, 34mg of nickel nitrate, 7.5mg of ferric nitrate and 200mg of sodium citrate, ultrasonically disperse for 20min, then cover and seal, and place at 120°C Heat treatment in a hydrothermal oven for 12 hours, filter after natural cooling, wash 3-5 times with pure water, and dry at 80°C for 10 hours to obtain NiFe-LDH / g-C with a NiFe-LDH content of 2.5wt%. 3 N 4 Two-dimensional ultrathin composite photocatalytic material, denoted as NiFe-LDH / g-C 3 N 4 -2.5.

Embodiment 3

[0032] NiFe-LDH / g-C 3 N 4 -5.0 Preparation of two-dimensional ultra-thin composite catalytic materials

[0033] Take by weighing 0.475g g-C prepared through embodiment 1 3 N 4 Put the powder in a polytetrafluoroethylene tank, add 25mL n-butanol and 25mL purified water, then add 200mg urea, 67mg nickel nitrate, 15mg ferric nitrate and 400mg sodium citrate, ultrasonically disperse for 20min, then cover and seal, place in 120℃ water Heat treatment in a hot oven for 12 hours, filter after natural cooling, wash 3-5 times with pure water, and dry at 80°C for 10 hours to obtain NiFe-LDH / g-C with a NiFe-LDH content of 5.0wt%. 3 N 4 Two-dimensional ultrathin composite photocatalytic material, denoted as NiFe-LDH / g-C 3 N 4 -5.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com